Products

Manufacturing Product News

Looking for information on the latest products in the industrial world? Look no further! Check out our product overviews below.

The Latest Updates in Technology

For more than a decade, we at Fabricating & Metalworking Online have carried stories on the latest machines and equipment to hit the market. Take a look at our latest updates, go back in our archives to see what we’ve written about in the past.

Filter by Process Zone:

Aluminum Filler Metals Approved for Wrought Commercial Applications

Maxal offers patent-pending 4943 aluminum MIG wire and TIG cut-lengths for a higher-strength aluminum welding solution that also offers the advantages of using a 4043 aluminum filler metal, including excellent corrosion resistance, ease of welding and low hot cracking sensitivity. It is also suitable for elevated temperature applications, and provides the ability to reduce weld size without compromising strength.

Malleable Cast Iron Clamping Squares for Modular Welding Tables

BuildPro Malleable Cast Iron Clamping Squares from Strong Hand Tools are 4-face Heavy Duty Clamping Squares that feature a total of 26 mounting holes over three surfaces for unlimited options in fixturing with the BuildPro Modular Welding Tables.

Virtual Reality Simulator Expands Support for Lap Joint On Mild Steel, Aluminum, Stainless Steel

The fifth VRTEX® Extensions™ software upgrade from Lincoln Electric includes a lap joint weld coupon with support for mild steel, aluminum and stainless steel in the virtual welding simulation environment – increasing the number of available and supported welds on the system from 105 to 141.

Pipe Purging Systems for Pre-Heated Pipe Welding

Huntingdon Fusion Techniques has developed “HotPurge™” Pipe Purging Systems for use up to 300 deg C (572 deg F) for 24 hours.

New Product Catalogs On Filler Metal Solutions

One new Hobart® catalog includes products currently branded as Tri-Mark® by Hobart, alongside Hobart products. The catalog also features aluminum products formerly branded as MAXAL®. The other new catalog is the McKay® by Hobartcatalog, which features stainless steel and hardfacing wires.

Combination Torch Welds Up To 1 Inch Thick, Cuts Up To 8 Inches Thick

The Purox Elite Series Combination Torch from ESAB includes the WH-4200 welding handle and the CA-4200 cutting attachment. The torch delivers superior safety with its tubeless extruded handle that minimizes the potential of gases mixing in the handle.

MIG Gun Nozzles Minimize Changeovers, Reduce Costs

Quik Tip™ HD Series nozzles from Bernard feature a removable nozzle cone and offer an increased wall thickness and insulating material to help them withstand the heat of the welding arc for longer periods of time.

Versatile 5-Face Bridgeport VMCs for the Job Shop

Two new 4+1 axis vertical machining centers from Hardinge are designed to achieve maximum capacity and performance in the job shop, OEM, aerospace, medical, electronic, defense, automotive and power generation industries, as well as many other manufacturing sectors.

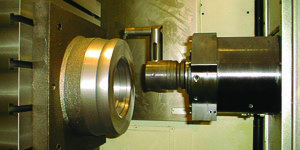

HMC Turn-Cut Function Eliminates Need for Secondary Turning

Turn-Cut processes work on Okuma MA and MB series of horizontal machining centers without the need to use secondary machinery for a turning application. In some cases, it can also be retrofitted to an existing Okuma machining center.

5-Axis HMC is Right Sized for Small Aerospace Parts

The a61nx-5E from Makino is uniquely sized for small components, featuring 3D contours without compromising the highly productive spindle performance and 5-axis capabilities of larger aerospace machines.

5-Axis HMC for Large Industrial, Energy and Aerospace Job Shop Production

The rigid design, versatile cutting capabilities and sizable work envelope make the T1 5-axis horizontal machining center from Makino an ideal fit for machining both soft and hard metals.

Smart HMC with User-Friendly Interface for Heavy Duty Machining

The intelligence system of the Tongtai HA-500II horizontal machining center from Absolute Machine Tools includes a tool management system, maintenance map, integrated monitoring of the hydraulic system and cooling system to avoid thermal fluctuation and vibration, and centralized management of the air pressure and lubrication systems.