April 2014

This issue is designed to help our readers research, plan and execute some of their most successful strategic investments over the coming year.

Infor VISUAL enables Tube Specialties, a fabricator of complex tube assemblies, to improve their overall productivity and shop efficiency, and support customer requests without spending excessive time and absorbing additional costs.

Manufacturing employment can grow by more than 300,000 jobs every year and the economy can grow by an additional $1.5 trillion. It all comes down to products, people and policy.

This issue is designed to help our readers research, plan and execute some of their most successful strategic investments over the coming year.

Tooling U-SME introduced a new industry resource, Competency Framework, to address the labor gap in manufacturing.

Explore the technical advancements these forming and fabrication technologies bring to the shop floor and assess which ones can give your business a competitive edge.

Detailed information about specific companies, their products, and product applications.

Infor VISUAL enables Tube Specialties, a fabricator of complex tube assemblies, to improve their overall productivity and shop efficiency, and support customer requests without spending excessive time and absorbing additional costs.

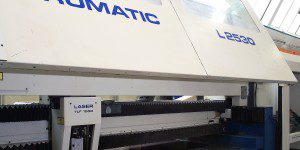

European Electrical Laminations uses Lantek Expert CAD/CAM software on its Trumpf laser cutting machines to produce electrical laminations for stators and rotors, armatures, stator segments, and pole laminations for motors and generators used in wind turbines, high speed rail and power generation.

The integrated control system inside this standard casting cell with trim press from Reis Robotics saves the Pierburg foundry up to 30 percent on energy consumption.

A review of some of the latest advancements in a variety of metal cutting technologies that offer reduced cycle times, improved quality and increased shop floor productivity.

Detailed information about specific companies, their products, and product applications.

Manufacturing employment can grow by more than 300,000 jobs every year and the economy can grow by an additional $1.5 trillion. It all comes down to products, people and policy.

BSL Industries aims to generate three times more money per employee than the industry standard by using advanced machine tools from DMG Mori Seiki to specialize in the top five percent of complex, difficult-to-manufacture parts for the power generation and oil & gas industries.

The U6 universal machining center from MAG/Fives Machining is engineered for lean manufacturing of large complex-geometry parts, with 5-axis machining and contouring capabilities that are ideal for heavy cuts in large cast iron, steel, Inconel or titanium parts used in aerospace, off-road, energy, marine and mining equipment.

Super-NURBS advanced programming functionality for CNC machining from Okuma is excellent for machining parts with high-accuracy requirements such as those for mold & die and aerospace/defense.

Alstom Power Hydro Lam turned to SCHIESS GmbH to enable it to work on large components used in hydro turbines.

A technical catalog of welding technologies that can increase welder productivity, reduce operating costs and improve part quality.

Detailed information about specific companies, their products, and product applications.

KUKA Systems and its sister company’s friction welding systems are proving increasingly important in the manufacturing industry with their almost limitless applications.

The Fronius AccuPocket combines the mobility welding technicians have been seeking with the reliable power, quality control and battery technology the job demands.

Some of the latest maintenance tools, equipment and software that will improve the backbone of any metal fabrication shop.

Detailed information about specific companies, their products, and product applications.

This modular micro-filtration system with Vomat FA-series high-performance filter technology is a critical part of any metal processing operation.

Detailed information about specific companies, their products, and product applications.

Examine how some of these tooling and workholding technologies can improve workpiece clamping and fixturing, increase cutting speeds and feeds, boost metal removal rates and significantly shorten cycle times.

Detailed information about specific companies, their products, and product applications.

Stanley‘s Spiralock thread form has been used in applications for NASA’S Space Shuttle, the Saturn Cassini orbiter, and more.

Some snapshots of the latest technical innovations in metrology that will improve measurement precision, increase inspection efficiency, and reduce the overall cost of quality on the shop floor.

Detailed information about specific companies, their products, and product applications.