April 2020

Digital Issue

Welcome to our annual Product Showcase and Buyers Guide. We publish this special issue each year to better serve our readers in job shops, metal service centers, contract manufacturing plants, OEMs and other companies by helping them become aware of and more familiar with some of the new machinery, equipment, tooling, software and other systems, accessories and services that are available to offer them a competitive advantage in their operations. We hope this issue helps you to research, plan and execute some of your most successful strategic investments over the coming year.

Subscribe View Digital IssueEquipped with servos for the X, Y, and Z axes, Tormach’s 1100MX is up to three times faster than the company’s 1100M and 770M mills. The machine delivers speeds of up to 10,000 rpm.

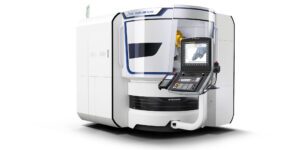

MC Machinery’s Eagle V5 can perform high-precision cuts with the X, Y, Z, B, and C axes moving simultaneously. Integrated 4/5-axis system allows X, Y, and Z travels of 21.6 in, 15.7 in, and 15.7 in, respectively.

Designed for workforce development, certification programs, and trade schools, Yaskawa Motoman’s EduCart features a six-axis robot, Schunk gripper package 3D-printed fingers and control interface, and laser scanner.

Huntingdon Fusion Techniques HF’s PurgEye 1000 measures 1 ppm to 1,000 ppm of oxygen from up to 1 kilometer away. Integrated networking device can share the reading from the monitor with another piece of equipment, such as a visual warning accessory or dew point monitor.

PurgElite from Huntingdon Fusion Techniques HFT tube and pipe purging systems help welders quickly achieve a clean, oxide-free, zero-color weld. Manufactured for diameters from 1 in to 24 in (25 mm to 600 mm), their integral gas feed device eliminates complicated valving for the operator to adjust and set.

Off-the-shelf inert gas feed hoses from Huntingdon Fusion Techniques HFT ensure argon, helium, and other gas arrives uncontaminated. The hoses can also be supplied to all other TIG/GTAW welders as well as laser operators with their own special fittings as required.

Featuring three welders and a plasma cutter, Forney Industries releases a refreshed and enhanced equipment line crafted for reliability, simplicity, and affordability: the 220 ST PRO Welder, 220 Multiprocess Welder, 220 AC/DC Welder, and 40 P Plasma Cutter.

A new machine size in powder nozzle technology, DMG MORI’s Lasertec 3D hybrid is designed for the additive manufacture of complex prototypes and small series parts as well as component repair and coating. It enables additive manufacturing and CNC milling on one machine – for 3D components in finished part quality.

Amada Miyachi America’s compact MM-410A supports process development and production applications for resistance welding technologies including AC, DC inverter, AC inverter, transistor, and capacitive discharge. Data storage is available using an onboard flash drive.

Venjakob/Nutro offers cleaning, pretreatment, coating, drying, and automation. Working with their customers’ paint manufacturers, the company develops tailor-made, highly technical concepts to meet challenging requirements.

Featuring a reinforced shank that helps resist breakage, 3X Power blades from L.S. Starrett cut metal and other materials more efficiently. A version with heat-treated teeth set at a super-aggressive pitch cuts fast in applications such as demolition and emergency vehicle extrication.

Local CAD installation isn’t required for importing files with SigmaNEST 20. The latest release of SigmaTek’s flagship product offers many new features that focus on improving user experience, material utilization, and data management.

Optomec’s LENS LDH 3.X brings the flexibility and versatility to build, repair, coat, and clad parts into one deposition head. Variable optics system that creates three focused spot sizes optimizes directed energy deposition (DED) processing across a range of parts and applications.

The automatic tool changer (ATC) for the BH series of dual-drive press brakes from MC Machinery Systems is designed for high-mix, low-volume environments by allowing for the greatest tooling variation on the market and facilitating operation by employees of all skill levels.

LVD Strippit’s Dyna-Cell with Easy-Form Laser in-process adaptive bending system and programming wizard ensure the desired angle from the first bending operation. Together, the features facilitate automated bending at speeds up to 1 inch (25 mm) per second.

The DMP Flex 350 from GF Machining Solutions is the successor to 3D Systems’ ProX DMP 320 3D metal printer. Consistent repeatability is achieved with its pure, low-oxygen environment during printing.

The FormBalancer FB42 shapes metal without relying on trouble-prone bladders. FluidForming Americas’ environmentally-friendly process uses high-pressure water instead of hydraulic oil as the forming liquid.

DMG MORI expands its selective laser melting (SLM) machine lineup with the Lasertec 12 SLM and Lasertec 30 SLM. Both machines feature the rePLUG module, which enhances safety and enables powder to be changed within two hours.

With longer reach and heavier weight capacities, Denso Robotics’ VM-VL series excels in large part assembly, long-reach computer tool tending, palletizing and depalletizing, material removal and deburring, and 3D bin picking. The two models also feature enhanced internal wiring for safer, more efficient operations.

Simulation and automated functions expedite commissioning new press feeding lines from COE Press Equipment. User-friendly interface and 10-in touchscreen simplify entry of machine setup information as well as troubleshooting.

ms Topcoater Elite Series 5 and ms Topcoater Speedy Series 4 provide high-quality powder coating with an easy-to-use, multifunctional cart. Configurations include single- or dual-gun, box-feed vibrating bed, or fluidizing container.

With functions such as choice of tool clamp and back gauge systems and a closed O-frame design that provides space for applications along the entire bending length, the Xpress press brake from Bystronic provides an impressive price-to-performance ratio.

BLM Group’s Twincut sawing machine more than doubles output with optional double-bar configuration. Cut bundles of aluminum and steel tubes of many shapes and a maximum length of 20 feet.

Bihler 4 Slide-NC Inc. automates processes in four-slide manufacturing, speeding setups to between five and 30 minutes. New method synchronizes operations with high-performance processing modules and controller for process monitoring.

b+s group combines cut-to-length and slitting lines at a speed of up to 100 m/min. The time-saving process also incorporates inspection measures that make this sheet metal processing suitable for sensitive surfaces like stainless steel and aluminum strips.

Automatic Feed’s three new models handle many material types as well as a range of widths, thicknesses and yield strengths. Gearboxes powered by AC servo-driven motors help achieve high precision and accuracy.

CAD design to final modeling is expedited with ABB’s RobotStudio for low-volume, high-mixing printing. Users program robots to complete production prototypes in 30 minutes.

6K’s UniMelt microwave plasma platform converts recycled material into premium powder. The technology processes almost any metal type, alloy, or ceramic feedstock, which means any alloy that’s machined has the potential to become powder.

L.S. Starrett’s 16 hardness-testing solutions include seven Rockwell systems, eight Vickers systems, and one Brinell system. Suitable for internal and external testing via dolphin nose design, the No. 3823 and No. 3824 test carbon steel, alloy steel, cast iron, and nonferrous metals per 30 Rockwell hardness scales.

The F3SG-SR Series optical system from Omron Automation Americas provides finger, hand, arm/leg, and full-body protection at machine openings. The safety light curtain provides stable detection up to 66 feet (20 meters) even in harsh environments.

United Grinding’s Laser Line Ultra uses an 8-axis configuration and picosecond lasers to machine complex micro geometries in cutting tools regardless of the material’s hardness.

Equipped with servos for the X, Y, and Z axes, Tormach’s 1100MX is up to three times faster than the company’s 1100M and 770M mills. The machine delivers speeds of up to 10,000 rpm.

Featuring high-speed performance and load capacities that exceed existing full ball standards, these new ball screws from THK America are ideal for machine tools.

Accessories and adapters for SMW Autoblok’s manual APS and WPS stationary workholding systems ensure flexible clamping of nearly every geometry without interfering with machining or contours, making them ideal for 5-axis machining. Zero-point clamping reduces setup time up to 90%.

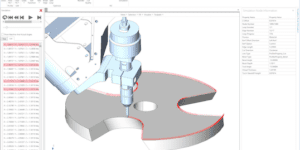

The latest version of hyperMILL 2020.1 CAD/CAM software from Open Mind Technologies includes 3D and 5-axis machining enhancements for complex parts as well as new automation and additive manufacturing strategies.

MC Machinery’s Eagle V5 can perform high-precision cuts with the X, Y, Z, B, and C axes moving simultaneously. Integrated 4/5-axis system allows X, Y, and Z travels of 21.6 in, 15.7 in, and 15.7 in, respectively.

Kays Engineering’s 3-axis DeHoff 1036 is designed for re-boring the CAM journals of automotive engine blocks. The single-spindle CNC boring machine has a capacity of 1 in (25.4 mm) and depth of 36 in (914 mm).

IBAG North America’s space-saving converter enables two microline spindles to operate simultaneously from one drive at speeds from 5,000 rpm up to 100,000 rpm.

Helios Gear Products introduces YG Tech’s Helios Hera 150 CNC machine to North America. The easy-to-program machine provides compact vertical hobbing for gears up to 6 inches (150 mm) in diameter.

Available for both electrochemical (ECG) and abrasive applications, Glebar’s Tridex CS1-E cutoff machine uses an electrochemical reaction to produce burr-free cuts on tubing from 0.012 inches to 3.15 inches in diameter.

Glebar’s CAM.3 is designed for the manufacture of guidewires with flats, multiple tapers, hex shapes, and other complex geometries as well as K wires, bone pins, orthopedic and sports medicine implants, instruments, and single-use disposable products 0.005 inches to 0.375 inches in diameter.

Sandvik Coromant’s solid carbide drills – the CoroDrill 860 with -SM geometry, the CoroDrill 860 with -GM geometry, and the CoroDrill 863 with -O geometry – improve consistency and performance on workpieces made from challenging materials such as heat-resistant super alloys (HRSAs), titanium alloys, and composites.

Designed for workforce development, certification programs, and trade schools, Yaskawa Motoman’s EduCart features a six-axis robot, Schunk gripper package 3D-printed fingers and control interface, and laser scanner.

A new machine size in powder nozzle technology, DMG MORI’s Lasertec 3D hybrid is designed for the additive manufacture of complex prototypes and small series parts as well as component repair and coating. It enables additive manufacturing and CNC milling on one machine – for 3D components in finished part quality.

The automatic tool changer (ATC) for the BH series of dual-drive press brakes from MC Machinery Systems is designed for high-mix, low-volume environments by allowing for the greatest tooling variation on the market and facilitating operation by employees of all skill levels.

The DMP Flex 350 from GF Machining Solutions is the successor to 3D Systems’ ProX DMP 320 3D metal printer. Consistent repeatability is achieved with its pure, low-oxygen environment during printing.

DMG MORI expands its selective laser melting (SLM) machine lineup with the Lasertec 12 SLM and Lasertec 30 SLM. Both machines feature the rePLUG module, which enhances safety and enables powder to be changed within two hours.

CAD design to final modeling is expedited with ABB’s RobotStudio for low-volume, high-mixing printing. Users program robots to complete production prototypes in 30 minutes.

The F3SG-SR Series optical system from Omron Automation Americas provides finger, hand, arm/leg, and full-body protection at machine openings. The safety light curtain provides stable detection up to 66 feet (20 meters) even in harsh environments.

Designed for workforce development, certification programs, and trade schools, Yaskawa Motoman’s EduCart features a six-axis robot, Schunk gripper package 3D-printed fingers and control interface, and laser scanner.

Strong Hand Tools’ Gas Grabber enables one person to safely and easily lift a heavy gas canister onto the company’s wheeled cart. Plasma cutting tray attaches to the Rhino Cart for greater versatility in mobile or stationary cutting, welding, and fabrication.

RoboVent’s Spire filtration units are still 3 ft by 3 ft, but have been completely re-engineered. The Spire for robotic weld cells and the Spire360 for ambient filtration come with more-absorbent filters that last longer and 7-in touchscreen controls for easier operation.

Thanks to integrated airflow sensors and three selectable flow rates, the optrel e3000X powered air-purifying respirator (PAPR) system from Optrel is certified to the highest class of breathing protection. Provides up to 18 hours of battery life.

Lincoln Electric’s Prism Compact fume-extraction system for welding and cutting applications incorporates the Prism line’s vertical filter technology. Available in indoor and outdoor configurations, the short unit fits efficiently into smaller spaces.

Four Magnum PRO Curve HDE semiautomatic welding guns from Lincoln Electric provide the best of both worlds: They deliver the highest duty cycle in their class and maximize operator comfort with a new ergonomic design.

Lincoln Electric’s Dual Maverick 200/200X is two welders powered by one diesel engine with two outputs, allowing two or more welders to work at the same time. Output remains steady even during arc stops and starts in dual mode.

Huntingdon Fusion Techniques HF’s PurgEye 1000 measures 1 ppm to 1,000 ppm of oxygen from up to 1 kilometer away. Integrated networking device can share the reading from the monitor with another piece of equipment, such as a visual warning accessory or dew point monitor.

PurgElite from Huntingdon Fusion Techniques HFT tube and pipe purging systems help welders quickly achieve a clean, oxide-free, zero-color weld. Manufactured for diameters from 1 in to 24 in (25 mm to 600 mm), their integral gas feed device eliminates complicated valving for the operator to adjust and set.

Off-the-shelf inert gas feed hoses from Huntingdon Fusion Techniques HFT ensure argon, helium, and other gas arrives uncontaminated. The hoses can also be supplied to all other TIG/GTAW welders as well as laser operators with their own special fittings as required.

Featuring three welders and a plasma cutter, Forney Industries releases a refreshed and enhanced equipment line crafted for reliability, simplicity, and affordability: the 220 ST PRO Welder, 220 Multiprocess Welder, 220 AC/DC Welder, and 40 P Plasma Cutter.

A new machine size in powder nozzle technology, DMG MORI’s Lasertec 3D hybrid is designed for the additive manufacture of complex prototypes and small series parts as well as component repair and coating. It enables additive manufacturing and CNC milling on one machine – for 3D components in finished part quality.

American Weldquip adds the Breath-Clean powered air-purifying respirator (PAPR) helmet to its weld fume-management lineup. Essentially a battery-powered gas mask, the helmet uses the same technology doctors and nurses use while treating contagious diseases.

Amada Miyachi America’s compact MM-410A supports process development and production applications for resistance welding technologies including AC, DC inverter, AC inverter, transistor, and capacitive discharge. Data storage is available using an onboard flash drive.

CAD design to final modeling is expedited with ABB’s RobotStudio for low-volume, high-mixing printing. Users program robots to complete production prototypes in 30 minutes.

The three-airflow process used by Parker Hannifin’s fabric-style SmogHog Media (SHM) collector virtually eliminates mist concentration. A 100% fully synthetic blend of fibers built into a tubular filter arrangement optimizes drainage.

The Venturi wet scrubber from Camfil Air Pollution Control (APC) improves workplace safety by collecting and removing potentially combustible airborne metal dust. It’s also suitable for processes that emit aerosols, fumes, gas, and vapors.

RoboVent’s Spire filtration units are still 3 ft by 3 ft, but have been completely re-engineered. The Spire for robotic weld cells and the Spire360 for ambient filtration come with more-absorbent filters that last longer and 7-in touchscreen controls for easier operation.

The three-airflow process used by Parker Hannifin’s fabric-style SmogHog Media (SHM) collector virtually eliminates mist concentration. A 100% fully synthetic blend of fibers built into a tubular filter arrangement optimizes drainage.

MicroCare Corp.’s Tergo metal cleaning fluid (MCF) avoids the regulatory issues of solvent-based vapor degreasers. By removing just enough binder to prevent damage during final sintering, the degreaser facilitates advanced processes such as additive manufacturing and injection molding.

Madison Chemical’s phosphate-free Aluma-Cling Blue eliminates having to brush by hand to clean bright aluminum and stainless steel. Clean-Gard 83 is an alkaline detergent that produces low-to-moderate foam, making it ideal for cleaning via ultrasonic cavitation.

IVEC’s fully automated Ultra ventilation system adjusts fan speed based on changes in velocity and/or air pressure. In addition to saving energy and extending filter life, maintaining air flow regardless of conditions ensures continuous particulate removal and lowers maintenance requirements.

The Venturi wet scrubber from Camfil Air Pollution Control (APC) improves workplace safety by collecting and removing potentially combustible airborne metal dust. It’s also suitable for processes that emit aerosols, fumes, gas, and vapors.

Featuring three welders and a plasma cutter, Forney Industries releases a refreshed and enhanced equipment line crafted for reliability, simplicity, and affordability: the 220 ST PRO Welder, 220 Multiprocess Welder, 220 AC/DC Welder, and 40 P Plasma Cutter.

The Detect-A-Finger Gen II from Rockford Systems helps protect fingers from pinch-point hazards and complies with Category 2 guarding device requirements. To make retrofitting older models quick and easy, the Gen II has the same mounting pattern as the original model.

The F3SG-SR Series optical system from Omron Automation Americas provides finger, hand, arm/leg, and full-body protection at machine openings. The safety light curtain provides stable detection up to 66 feet (20 meters) even in harsh environments.

IVEC’s fully automated Ultra ventilation system adjusts fan speed based on changes in velocity and/or air pressure. In addition to saving energy and extending filter life, maintaining air flow regardless of conditions ensures continuous particulate removal and lowers maintenance requirements.

IBAG North America’s space-saving converter enables two microline spindles to operate simultaneously from one drive at speeds from 5,000 rpm up to 100,000 rpm.

As 5-inch and 6-inch grinders become more prevalent in metal fabrication, Weiler Abrasives is providing larger-diameter consumables to ensure customers have the solutions to address all their grinding and finishing needs.

Capto toolholders and insert widths expand applications for users of the Cut MX grooving system. The TC410 Advance HSS-E thread former can be used universally for blind and through-hole threads in most materials.

Sandvik Coromant’s solid carbide drills – the CoroDrill 860 with -SM geometry, the CoroDrill 860 with -GM geometry, and the CoroDrill 863 with -O geometry – improve consistency and performance on workpieces made from challenging materials such as heat-resistant super alloys (HRSAs), titanium alloys, and composites.

Impregnated with premium silicon carbide grains on both sides, tear-resistant and waterproof fixed abrasive buff (FAB) buffing wheels from the Norton division of Saint-Gobain Abrasives last significantly longer than traditional cotton buffs.

With no setting required, even a novice can quickly install Monaghan Tooling Group’s Top Speed Ring (TSR) reamer. Four additional cutting heads ensure longer service life, saving time and money.

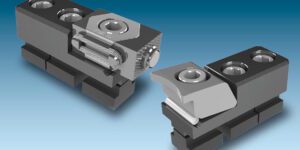

The Pitbull and OK-Vise clamps from Mitee-Bite Products generate over 20,000 lbs of pressure. Among the strongest, lowest-profile clamps in the industry, they can be used on the same base with different configurations.

Mount Kurt Manufacturing’s VersastileLock vises back to back to create an economical tombstone fixture for horizontal machining centers (HMCs) with work envelope size and weight limitations. The tool can be 200 to 300 lbs lighter than a tombstone with clamps or vises.

Bilsing Automation’s single-pipe tooling is easy to configure, has a compact design to minimize collisions, and provides Industry 4.0 features. Combined with a carbon fiber beam, the tooling can also reduce cycle times.

Strong Hand Tools’ Gas Grabber enables one person to safely and easily lift a heavy gas canister onto the company’s wheeled cart. Plasma cutting tray attaches to the Rhino Cart for greater versatility in mobile or stationary cutting, welding, and fabrication.

Featuring three welders and a plasma cutter, Forney Industries releases a refreshed and enhanced equipment line crafted for reliability, simplicity, and affordability: the 220 ST PRO Welder, 220 Multiprocess Welder, 220 AC/DC Welder, and 40 P Plasma Cutter.

Featuring a reinforced shank that helps resist breakage, 3X Power blades from L.S. Starrett cut metal and other materials more efficiently. A version with heat-treated teeth set at a super-aggressive pitch cuts fast in applications such as demolition and emergency vehicle extrication.

L.S. Starrett’s 16 hardness-testing solutions include seven Rockwell systems, eight Vickers systems, and one Brinell system. Suitable for internal and external testing via dolphin nose design, the No. 3823 and No. 3824 test carbon steel, alloy steel, cast iron, and nonferrous metals per 30 Rockwell hardness scales.

Rigaku’s KT Series of laser-induced breakdown spectroscopy (LIBS) analyzers for metal forming, fabricating, welding, and finishing includes the KT-100S. Via the Drill Down feature, the analyzer automatically burns through imperfections to obtain a clean reading.

The Vanta Element from Olympus Scientific Solutions Americas provides the same fast material- and alloy-grade identification as the line’s other models in a rugged, cost-effective package. The 2.9-lb X-ray fluorescence (XRF) analyzer works in temperatures ranging from 14 degrees F to 113 degrees F (-10 degrees C to 45 degrees C).

Mitutoyo America Corp.’s QM-Height Series measures height, height difference (step), inside/outside widths, inside/outside diameters, circle pitch, and free-form surface max/min heights to ±(2.4+2.1L/600) μm. Simple-to-use control panel enables most measurements to be made with one keystroke.

The M62 Scan from Marposs relieves the workload of gear lab machines by enabling an interim check directly on the shop floor. The universal inspection system can reach speeds of up to 50 mm/s, helping to improve production processes.

Mahr Inc.’s Precimar ICM 100 IP can be retrofit to automatically calibrate dial and digital indicators, test indicators, and dial comparators. Six higher-resolution options expand potential applications for MarCator 1086R-HR and 1087R-HR digital indicators.

The coordinate measuring machine (CMM) manufacturer is entering the portable measuring arm market with the Freedom line of 24 3D articulating arms. A 6-axis model for touch probing and a 7-axis version for multisensor metrology including laser scanning are available in two accuracy levels.

Kurt Manufacturing’s gaging systems range from manual operation to fully automated and include SPC software and PC integration, custom engineering, and final testing. They’re ruggedly designed to provide many years of use processing tens of thousands of parts.

Hexagon Manufacturing Intelligence’s R12 is a 12-megapixel version of the company’s AICON SmartScan white light scanner. The higher-resolution camera increases the accuracy of a system known for versatility and portability.