August 2011

While it is quite common to evaluate the purchase of a laser cutting machine in great detail, much less consideration is given to what is required to keep that system in continuous operation. Lukas Baechler of TRUMPF explains how, when automation is done properly and the right equipment is used, all of the components required for an individual system will run with a perfect flow of material, better quality, and lower costs per part.

Accurately troubleshooting problems with the delivery of the welding wire to the weld pool and the current to the wire when they arise or, better yet, avoiding them before they arise, is crucial to maximizing the benefits that these processes offer.

Doing More With Less: Guest columnist Dale Petts of Simonds International sees a perfect storm brewing as baby boomers retire and young people view factory work as dirty, dangerous and unfulfilling. But he also sees an industry that is discovering how online training technology can build the competitive value of its workforce.

While it is quite common to evaluate the purchase of a laser cutting machine in great detail, much less consideration is given to what is required to keep that system in continuous operation. Lukas Baechler of TRUMPF explains how, when automation is done properly and the right equipment is used, all of the components required for an individual system will run with a perfect flow of material, better quality, and lower costs per part.

Technical insights and tips from Bret Molnar of Roll-Kraft on how to perform regular roll inspection and maintenance that extends roll life and improves performance by using micrometers, gauges, and a trained eye that can spot areas requiring attention before wear can get out of control.

Recent activities and events going on in the business of fabricating and metalworking.

People making recent headlines in the business of fabricating and metalworking.

HVAC contractor State Automatic Heating & Cooling saved money in labor and material costs by installing SimpleSox fabric ductwork from DuctSox instead of spiral metal duct to heat its own sheet metal shop in Chicago.

In an effort aimed at achieving a greater measure of customer service and reducing labor costs, Indiana-based steel service center Westfield Steel recently unveiled a new orbital stretch file wrapping machine technology built with some innovative in-house fabrication work for packaging its deliveries in a way that is more attractive and secure.

The cut quality, consumable life and reliability of the plasma cutters used in the past is just that – a memory of the past! Let’s evaluate the different categories of new plasma cutting systems to show how they can benefit those fabricators of steel parts that have traditionally used traditionally oxy-fuel cutting.

The More Things Change . . . Customers demand tighter radius bending, but no stock. Batch sizes have shrunk. Machine setup and scrap are critical to job pricing and costs. How is a job shop supposed to compete against all of this change? All-electric bending from Unison/Horn Machine Tools has an answer.

The technical consultation and equipment service that laser system distributor MSS Lasers provides enabled MPJ Fabrications to grow its business with reliable, advanced machinery at an affordable price.

Lowering the Total Cost of Ownership: The newest technology in punching cylinder axes from Bosch Rexroth promises metal fabricators they can maximize their nibbling, punching, engraving, soft punching and deep drawing – all while lowering their energy consumption.

Not Your Grandfather’s Process: The latest automated shot peening systems from Innovative Peening Systems boast a robust design that is integrated with smart, powerful motion control components from Siemens Industry to yield high-performance at an economical price.

To meet demands for wider flexibility in hole placement and accuracy, this Laserdyne 5-axis laser machining system from PRIMA North America allows precision job shop Aerofab to process complex turbine engine components along the full travel of the Z-axis at compound angles as shallow as 10 deg to the surface.

Flexibility is the key to making money in precision grinding. If you are looking for ways to reduce your grinder operating costs and improve your margins, check out the flexibility these machines offer.

Doing More With Less: Guest columnist Dale Petts of Simonds International sees a perfect storm brewing as baby boomers retire and young people view factory work as dirty, dangerous and unfulfilling. But he also sees an industry that is discovering how online training technology can build the competitive value of its workforce.

An offline personal computer can be used to train the operators, who then run the program on a virtual control to prove it out, all before running it on a costly machine tool . . . Randy Pearson of Siemens Industry explains how this evolution of the quasi-CAM system brings so many advantages to the shop.

Right angle grinders have traditionally used grinding wheels, fiber discs, wire brushes, and flap discs for stripping, deburring, blending, prepping and finishing. But David Long of Saint-Gobain Abrasives explains why non-woven abrasives are now replacing traditional coated abrasives as a faster and more cost effective method.

Accurately troubleshooting problems with the delivery of the welding wire to the weld pool and the current to the wire when they arise or, better yet, avoiding them before they arise, is crucial to maximizing the benefits that these processes offer.

The next generation of innovation and advances in industrial robot technology promise to increase your productivity in arc welding and other multipurpose applications.

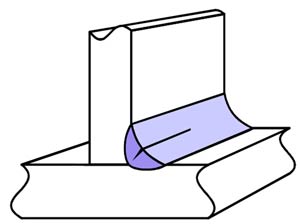

With equipment, weld procedures, filler metals, consumables and so many factors to monitor, it is inevitable that mistakes will occur in welding. But they don’t have to happen. Bernard, Hobart Brothers and Miller Electric review the most common mistakes that occur . . . and recommend how to solve them.

Robotic welding integrator Genesis Systems uses scalable, flexible DELMIA Robotics 3D digital manufacturing technology to get their systems to the build phase much quicker than their competitors, eliminating a huge amount of retool time, saving up to 30 percent in tool design and reducing design changes by 65 percent.

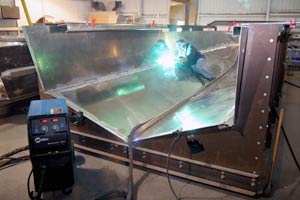

A welding robot typically uses a solid or metal cored electrode. Submerged arc welding (SAW) is an exception. Jeff Nadzam of Lincoln Electric explores how this highly efficient welding process is being embraced by East End Welding to deliver sound weld deposits that are lower in hydrogen, fuse well with parent materials, and create exceptional finished weld mechanical properties.

As the demands for energy continue to increase worldwide, fabricators serving this industry will be challenged to remain competitive by changing from the stick welding process to a gas-shielded flux-cored welding process. Tim Hensley of Hobart Brothers explains why they must carefully assess their quality needs and available labor or training ability before making this sort of switch.

Circumstances exist in which the selection of low-hydrogen, mild steel electrodes such as ER70S-6 solid wire or E7018 stick electrode is not enough to prevent weld cracking. Regis Geisler of Lincoln Electric explores the reasons for this and offer possible alternatives to these filler materials.

Due to the poor column strength of aluminum, the wire easily bends or twists when pushed through a typical GMAW wire feeder and gun system, causing “bird-nesting.” Thom Burns of AltoTec shares some ways to prevent this problem.

Moving Beyond “Wait and See”: Geoff Lipnevicius of Lincoln Electric examines how the hybrid revolution is building momentum as manufacturers embrace the higher travel speeds, increased depth of penetration and deposition rates of a ‘hybrid’ materials-joining process that captures the unique advantages of two distinct sources of energy – laser power and arc welding.

Reduce wear and stress on cables and hoses: Check. Prevent entanglement and improve operator safety: Check. Withstand high speeds and accelerations: Check. Cable carriers from igus can do it all and even be pre-configured online, too. Let’s see . . . Added value: Check.

Mine of Information: An old Gray horizontal boring mill used in the mining industry was electrically upgraded with CNC technology from NUM Corporation by automation systems integrator MasterControls to achieve higher precision, compatibility with RS274 G-code programming, probing functionality, and an industrial PC front-end with unlimited program storage and networking . . . all for a fraction of the cost of a new machine.

Even though a machine tool spindle is a high-precision machine component, more often than not it is handled carelessly, forced to perform well beyond design limitations, or otherwise abused to the breaking point. Ed Zitney of SKF Machine Tool Services shows how proper care and maintenance can make all the difference in both its operation and longevity in service.

Winner Take All: Imagine encountering a sluggish economy, technological change, industrial shifts and changes in consumer preferences, all at the same time. To compete within all of these challenges, Emerson Bearing restructured, increased the size of their warehouse and offered strategic inventories at several price points.

A review of the latest advancements in scrap conveyor technology for the economic removal of coil scrap, machine tool chips and magnetic separation of contaminates from PRAB, Jorgensen Conveyors and Polytech Filtration Systems.

It is not a difficult engineering challenge to design effective safeguarding for virtually any type of machine. Sergio Aguilar of Omron STI explains how the real challenge is to provide guarding that will deliver high levels of safety while also enabling high productivity and throughput.

Does the overall culture of a company have at least as powerful an influence on worker safety as the actions of the workers themselves? In exploring this controversial safety philosophy, Phil La Duke of Rockford Greene investigates whether an environment where people feel comfortable making and reporting mistakes is better equipped to determine the root cause of a problem and implement counter measures to prevent recurrence.

When collecting measurement data with a probe, the selection and use of the stylus becomes critically important because of the proliferation of probes in manufacturing – on machine tools, CMMs, portable arms – and the many different types of probes available, such as kinematic, strain gauge, scanning, etc. Dennis Bobo of Renishaw reviews the core points that you need to know before making that investment.