August 2013

Despite the benefits of automation, its complexity can intimidate first-time investors. Shops must learn how to effectively define, plan, justify, select, implement and execute a full system integration. To do this, they should become familiar with the process and the key considerations needed for a seamless integration.

The “leaner” a part is manufactured, the greater the justification to purchase a machine tool, tooling and programming with features that encompass this level of performance and provide the greatest advantages in productivity.

Every salesperson knows the job is tougher than ever, not for the faint hearted or those who feel the world owes them a living. But salespeople also recognize the importance of having an extra edge, of standing out from the crowd. Here are some ideas that can make a difference.

Which pump is right for your shop? Here is a look at how a water intensifier system operates, different system configurations, and the specific things to look for in the pump system regarding the waterjet application required.

These special custom enclosures and fuel tanks from Hennig meet the environmental and acoustic specifications of the water treatment facility required for three Cummins 2 MW generators powered by 16 cylinder QSK 60 series diesel engines.

The “leaner” a part is manufactured, the greater the justification to purchase a machine tool, tooling and programming with features that encompass this level of performance and provide the greatest advantages in productivity.

Every salesperson knows the job is tougher than ever, not for the faint hearted or those who feel the world owes them a living. But salespeople also recognize the importance of having an extra edge, of standing out from the crowd. Here are some ideas that can make a difference.

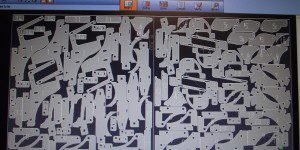

This engineering subcontractor explains how CAD/CAM project nesting technology has changed his life and completely revolutionized the way his job shop increased its workload capacity.

Roll formed tube materials from Roll Forming Corporation are effective for building operator compartment structures configured as cabs or frames that are intended to protect equipment operators and motorists from injuries caused by vehicle overturns or rollovers.

Recently, the spire for the One World Trade Center was permanently installed in New York City and with it, the building secured its place in Western Hemisphere history – along with the TruLaser 1030 laser cutting system from TRUMPF that made it.

Despite the benefits of automation, its complexity can intimidate first-time investors. Shops must learn how to effectively define, plan, justify, select, implement and execute a full system integration. To do this, they should become familiar with the process and the key considerations needed for a seamless integration.

The onset of robotics in machine shops both big and small has significantly impacted the CNC to a great degree already, but more changes are on the way.

Mike Riley reports on how manufacturers are supporting the emerging MTConnect® and ISO 13399 standards for sharing tool and machine data that will help job shops large and small improve their efficiencies and increase capabilities.

A breakthrough liquid-cooled generator technology marks the next generation of CNC Die Sinking that has revolutionized the way machine tool builders look at their power supplies.

As consumer products continue to shrink in size, die shops such as Scenic Tool and Stamping face the challenge of developing highly intricate tooling for stamping the tiny components that make up miniature merchandise. As a result, an increasing number of these shops are incorporating high-precision wire EDMs like the Cut 2000 from GF AgieCharmilles that provide automatic wire-changing capability.

uses the to easily switch wires of different sizes and materials.

The variety of shielding gases used in arc welding can be confusing as to when to use which gas for which application. Here are some basic guidelines to follow.

Because it can be difficult to properly evaluate the capabilities of a dust collection system, RoboVent recommends five things you should know to avoid getting burned when buying industrial ventilation equipment.

Though near miss reporting is a sacred cow among safety professionals, Phil La Duke of Environmental Resources Management examines why most shops waste vital resources and scarce funds relentlessly pursuing a goal that they cannot – and in most cases should not – achieve.

After paying $2 million annually in electricity costs, an old Simonds International factory installs new cogeneration technology from 2G-CENERGY to slash its electricity costs and carbon emissions.

Because it can be difficult to properly evaluate the capabilities of a dust collection system, RoboVent recommends five things you should know to avoid getting burned when buying industrial ventilation equipment.

An examination of some of the latest chucks, jaws, collets and other tool and workholding technologies that can help you reduce setup time, increase spindle utilization and improve your competitive edge.

These two technical studies from Ingersoll Cutting Tools examine how different machine shops are using next generation machining geometry to manage heat at the cutting edge.

A snapshot of some of the gages, quality software, calibration, CMMs, data collection, electronics test and non-contact inspection equipment being exhibited on the show floor at McCormick place in Chicago on September 10-12.

Permanent magnetic separators help draw out fine tramp metal along critical points of the production line. As such, they must be periodically tested for optimum strength. Here are the guidelines to follow from Eriez® on conducting a proper and valid magnet pull test.