August 2018

Digital Issue

The 2018 edition of the International Manufacturing Technology Show is on track to be one of the largest IMTS events ever at McCormick Place in Chicago from September 10-15. This show promises to help you stay ahead of your competition . . . and our special Show-in-Print provides technical reviews of some of the machinery, tooling, systems and accessories that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Subscribe View Digital IssueAs increasing demand for passenger and freight rail services fuels rapid growth in rail infrastructure investment, machining plays an invaluable role in the maintenance, repair and manufacture of numerous railway applications, including track, wheels and wagon parts.

There are rotatable necks, flex necks, ones with various bend angles and lengths, neck couplers and custom necks. Which one is the right style to use? Here are some considerations to remember that will help you choose the right MIG gun neck for your application.

Firefighters need high quality equipment that they can depend on, especially on the eve of wildfire season. For them, fast and effective water flow is essential, and here’s a closer look at how 3D printing and selective laser sintering technology helped redesign a water pump rotor three times faster than in the usual prototyping process.

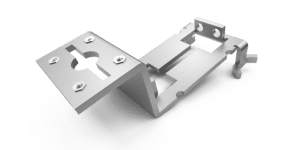

To reduce weight for lower deflection, Toyota Motor Manufacturing of Canada uses Accelerate Lightweight Tooling from Destaco for higher precision, reduced scrap and improved operational efficiency on their stamping press.

The No. 831 oven from Grieve has a 12 in long open belt loading zone, 54 in long insulated heat zone with recirculated airflow, 12 in long open unloading zone and 10 in wide, 0.041 in high carbon steel woven wire conveyor belt with 1/40 hp motor variable speed drive.

Take a journey through fabricating, metal forming, laser and waterjet-based machining, including displays of welding, metal treating and marking equipment that highlight in-process monitoring and multi-functional beam capabilities.

Ideal for marking reusable surgical instruments and endoscopes, the TruMicro 2000 picosecond laser from TRUMPF is suited for applications ranging from high quality metal engraving to cutting extremely thin films, to corrosion-free marking of medical instruments and chrome-plated plastics.

For use in high temperatures, contamination, aggressive media or for cleanrooms, the nearly maintenance-free PGN-Plus-P universal gripper from SCHUNK accommodates longer fingers and higher workpiece loads.

With the new ISO 14955 standards, energy efficiency is likely to become an increasingly important quality attribute of modern machine tools.

Additive manufacturing enables layer by layer processes to fabricate three dimensional products. See the continued improvements in materials and processes that are producing more industrial additive solutions than ever.

Firefighters need high quality equipment that they can depend on, especially on the eve of wildfire season. For them, fast and effective water flow is essential, and here’s a closer look at how 3D printing and selective laser sintering technology helped redesign a water pump rotor three times faster than in the usual prototyping process.

Here are gear cutting, forming and finishing, broaching, shaping and slotting systems used for automotive, construction, mining and shipbuilding, alternative energy and wind power applications.

This process development is a viable and very cost-effective alternative to conventional grind-and-hone operations for automotive powertrains and other gear market segments, yielding a highly attractive cost per piece, extended tool life scenario, reduced capital outlay and more consistent end product bode.

These advanced systems are the very foundation of the machine tool industry, where you’ll find the

latest innovations in metal cutting equipment, machining centers, turning centers, drilling, boring, milling, and more.

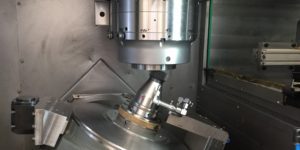

The Tongtai SH-5000P Horizontal Machining Center from Absolute Machine Tools can exceed the demands of any shop with high volume machining needs.

From CNC wire EDM equipment to die sinking machines, this reliable, high accuracy technology is ideal for tool and die applications, especially shops doing one-off or specialty components.

This is the world of custom systems automation and the latest software that is needed to extract the maximum efficiency from your machine tools and optimize your plant operations with cost efficiency.

For use in high temperatures, contamination, aggressive media or for cleanrooms, the nearly maintenance-free PGN-Plus-P universal gripper from SCHUNK accommodates longer fingers and higher workpiece loads.

Newly redesigned ICECUT 100 and 200 mag drills from Walter Surface Technologies guarantee productive drilling with almost no risk of motor overloading, overheating, or premature cutter breakage.

With the new ISO 14955 standards, energy efficiency is likely to become an increasingly important quality attribute of modern machine tools.

These are systems for applications requiring high tolerance and precision surface finish, including grinding technology, sawing and cutoff machines and a variety of finishing systems, such as lapping, balancing, honing and polishing machines, as well as advancements in abrasive size, shape or composite materials, and nano-materials for improved surface finishes in more constrictive areas.

The SURFOX 305 electrochemical MIG and TIG weld cleaning system from Walter Surface Technologies quickly removes heat tint from the heat-affected zone of MIG, TIG, and spot welds on stainless steel and aluminum.

Being nimble to meet project timelines is important to Sigma Thermal. Take a closer look at how their investments in new pipe welding equipment and technologies increased their productivity while keeping quality at the forefront.

There are rotatable necks, flex necks, ones with various bend angles and lengths, neck couplers and custom necks. Which one is the right style to use? Here are some considerations to remember that will help you choose the right MIG gun neck for your application.

Do you need faster travel speeds, reduced spatter levels and improved control over arc starts to boost efficiencies or improve your MIG weld quality? With some training and a little practice, pulsed MIG welding can drive the improvements you need. Here are some factors to consider whether it is a good alternative for your operation.

To stay competitive, many shops must choose between building a robotic workcell or buying a turnkey system. DIY robotic integration is possible, but certain critical factors should be considered because the end user assumes greater responsibility and acquires more project risk. There is much to know and manage, from process welding requirements and robotic cell design to tooling requirements and system documentation.

The SURFOX 305 electrochemical MIG and TIG weld cleaning system from Walter Surface Technologies quickly removes heat tint from the heat-affected zone of MIG, TIG, and spot welds on stainless steel and aluminum.

The complete spectrum of industrial automation, IT, power transmission and fluid power technology for shops needing cross-sector and cross-platform systems and digital integration to meet ever-changing market demands.

For wiping wire, drying inks, cooling hot extruded shapes, and blowoff of water, plating, coatings and dust, the 3/8 in Super Air Wipe from EXAIR produces a 360 deg airstream that can blow off, dry, clean or cool the material passing through it.

To run your plant effectively, these are the goods that are necessary to help make parts, service and monitor your machines, and operate a safe and environmentally responsible facility.

5S design of an industrial work environment by Hoffmann Group can guarantee plant aesthetics and operational functionality even when future changes are made, so that employees still feel good in their workspace and remain productive.

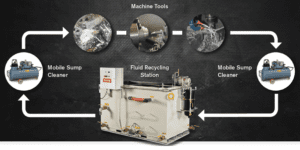

Are you concerned about the rising expenses associated with your waste management? Do you need a more effective and profitable way to reclaim and recycle your valuable metalworking fluid? Modern fluid reclamation systems use innovations that can provide a fast return on investment while improving your profits, equipment life and employee safety.

Personal Air Conditioning Vests from Vortec circulate cool air to minimize temperature-related stress and fatigue, thus improving comfort and productivity.

5S design of an industrial work environment by Hoffmann Group can guarantee plant aesthetics and operational functionality even when future changes are made, so that employees still feel good in their workspace and remain productive.

With the new ISO 14955 standards, energy efficiency is likely to become an increasingly important quality attribute of modern machine tools.

The latest tooling technology and state-of-the-art workholding systems are designed to minimize setup times and machining cycles, increase productivity and cost efficiency on machine tools, give new capabilities to older equipment and maximize the investment in your machinery and equipment.

As increasing demand for passenger and freight rail services fuels rapid growth in rail infrastructure investment, machining plays an invaluable role in the maintenance, repair and manufacture of numerous railway applications, including track, wheels and wagon parts.

Curls, hinges, knuckles, and rolled edges can all be produced on sheet metal using either a punch press or a press brake. The primary difference is the amount of control and handling provided by the machine. When producing curl forms, here are some factors to consider to make sure the job is done right.

Are you trying to blend and finish curved parts and other jobs where it’s difficult to reach the work or when a specific material finish is a priority? Trimmable flap discs are a versatile solution for these applications because the flaps and backing plate will also curve to match the shape during the process.

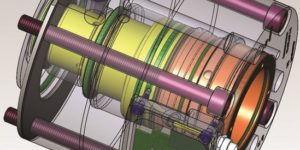

Using the ROTA NCR 6-jaw power chuck from SCHUNK, even pre-machined parts with diameters up to 1,200 mm can be perfectly centered on large lathes without deformation of the workpiece.

The newest metrology equipment, systems and software to keep your processes on track with absolute confidence and security in the quality of your production output, as well as instruments and devices that check the accuracy of your machines – an important step in protecting your investments.