August 2019

Digital Issue

Additive manufacturing is moving beyond prototypes, part repair and producing non-critical parts, and entering the direct production of critical parts and lot sizes. To deliver these jobs quicker, digital networks are integrating AM with product design software, CAD/CAM, ERP and automation to develop new approaches that can build innovative products faster than ever.

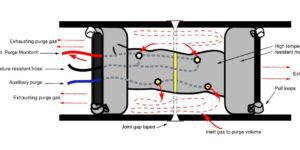

Subscribe View Digital IssueInconel 740H and other new superalloys provide major improvements in mechanical properties and corrosion resistance at elevated temperatures, but they still need careful purging during welding in order to preserve these characteristics.

These best practices for welded moment connections and column splices in the field require an up-front investment of time and money, but considering how much you’re likely leaving on the table, it’s a small price to pay.

Digital tools are already here in the form of DROs and one-way communications to mobile devices, but that’s only the beginning. Get ready for some exciting breakthroughs in automation that promise higher productivity, increased safety, greater throughput and less scrap.

Additive manufacturing is moving beyond prototypes, part repair and producing non-critical parts, and entering the direct production of critical parts and lot sizes. To deliver these jobs quicker, digital networks are integrating AM with product design software, CAD/CAM, ERP and automation to develop new approaches that can build innovative products faster than ever.

Additive manufacturing is moving beyond prototypes, part repair and producing non-critical parts, and entering the direct production of critical parts and lot sizes. To deliver these jobs quicker, digital networks are integrating AM with product design software, CAD/CAM, ERP and automation to develop new approaches that can build innovative products faster than ever.

These profile/angle bending machines can meet your fabrication needs for working with square, flat, and angle iron.

How simulating the factory can help fix mistakes and improve production.

To prevent lower quality parts and frequent tool replacement, keep your punch press tooling sharp and well maintained to achieve the greatest number of hits possible for the best possible return on your investment.

Robotic automation of machine tending can add value to operations in more ways than one. By considering these concepts and combining best practices with high performance robots and peripherals, operational inefficiencies will diminish, paving the way for a more productive future.

This is now a defining element in laser tube processing as shops compete within narrower pricing margins to meet product demands for improved quality and enhanced features. Here’s why.

A new catalog from Metabo features detailed specifications for metalworking, cordless systems, accessories and specialty and problem solver tools.

Optimized, faster cutting speeds. Reliable accuracy. Easy programming of advanced control capabilities. Lower maintenance and reduced operating costs. And all at a reasonable price. Welcome to the newest EDM systems.

How simulating the factory can help fix mistakes and improve production.

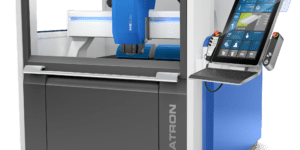

The M8Cube Next high-speed milling machine from DATRON Dynamics is ideal for precision, high or low volume production of electronic, aerospace and medical parts, as well as industrial engraving applications.

To eliminate burning, melting and heat related breakage in small machining operations, the Mini Cooler with Dual Point Hose Kit from EXAIR provides a stream of 20 deg F cold air to prevent heat buildup, reduce downtime and increase productivity.

Robotic automation of machine tending can add value to operations in more ways than one. By considering these concepts and combining best practices with high performance robots and peripherals, operational inefficiencies will diminish, paving the way for a more productive future.

Here are a few things to consider before shopping that will help you find the equipment and terms best suited to your needs.

A new catalog from Metabo features detailed specifications for metalworking, cordless systems, accessories and specialty and problem solver tools.

These weld fume extraction and filtration systems can effectively protect operators and nearby workers and reduce their health risks from fumes, dust and other contaminants.

Inconel 740H and other new superalloys provide major improvements in mechanical properties and corrosion resistance at elevated temperatures, but they still need careful purging during welding in order to preserve these characteristics.

These best practices for welded moment connections and column splices in the field require an up-front investment of time and money, but considering how much you’re likely leaving on the table, it’s a small price to pay.

How simulating the factory can help fix mistakes and improve production.

Hot Tap Digital Flowmeters from EXAIR allow installation when compressed air piping is under pressure by eliminating the need to isolate and remove pressure from the pipe.

A new catalog from Metabo features detailed specifications for metalworking, cordless systems, accessories and specialty and problem solver tools.

This flexible tool adapter system for right-angle heads can slash changeover time on almost any lathe or mill using a single live tool – without having to commit to a quick-change system on the initial purchase – and significantly reduce inventory for the busy shop.

Any point that an individual is interacting with, counting or scanning a tool creates opportunities for value to be captured and efficiencies to be improved.

Digital tools are already here in the form of DROs and one-way communications to mobile devices, but that’s only the beginning. Get ready for some exciting breakthroughs in automation that promise higher productivity, increased safety, greater throughput and less scrap.

To prevent lower quality parts and frequent tool replacement, keep your punch press tooling sharp and well maintained to achieve the greatest number of hits possible for the best possible return on your investment.

A new catalog from Metabo features detailed specifications for metalworking, cordless systems, accessories and specialty and problem solver tools.

By automatically locating the cutting edge with one simple touch for quick measurement, the Microset UNO Autofocus tool presetter from Haimer minimizes incorrect data inputs.

These borescopes help machine shops inspect automotive, aerospace, hydraulic and other precision parts with difficult geometries for internal burrs, defects, surface finish irregularities and more inside deep or narrow bores.

Exact Metrology worked with artist Tom Tsuchiya to create relief figures of the 1869 Cincinnati Reds team.