August 2020

Digital Issue

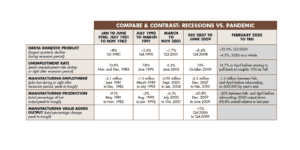

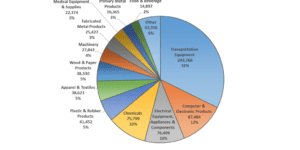

Bringing Manufacturing Back: The global pandemic has revealed the fundamental flaw of relying on only one or two overseas manufacturers of metal parts, components, and assemblies: Companies pay less up front, but now are scrambling to fill their customers’ orders. Here’s how to grab your piece of the pie as U.S. companies search for local partners.

Subscribe View Digital IssueModeling deeply intentional and thoughtful leadership, the CEO of a machining company equips his team mentally and digitally to muscle through myriad obstacles –– and emerge victorious for their customers and themselves.

Nothing frustrates improvement efforts like software programs that don’t play well together. Brothers Brian and Mitch Olson made sure that didn’t happen when they launched their CNC machining shop by deploying a solution that integrates resource planning and quality management.

New technology is making the flap disc a cost-effective and equally effective alternative to grinding wheels in a variety of applications. They’re versatile, lightweight, easier to control, and convenient.

The global pandemic has revealed the fundamental flaw of relying on only one or two manufacturers of metal parts, components, and assemblies: Companies pay less up front, but are scrambling to fill their customers’ orders. Here’s how to grab your piece of the pie as U.S. companies search for local partners.

Convenience is key when there’s need for a chemical label or OHSA/ANSI sign related to a metal forming, fabrication, or other production process. Create, replace, or update critical safety information quickly and easily with Graphic Products’ DuraLabel Kodiak industrial sign and label printer.

Armed with application-specific software and a controller that coordinates operation of the robot and painting devices, the three machines that comprise Yaskawa Motoman’s MPX Series precisely dispense paint on components of virtually any size.

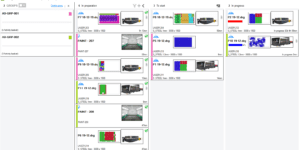

The latest version of ShopFloorConnect OEE and Shop Floor Data Collection Software from Wintriss Controls Group makes customization easier and offers flexible scheduling capabilities as well as machine interface enhancements.

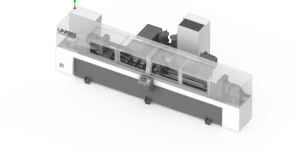

Tridex Technology’s CS1-E electrochemical machine cuts multiple tubes simultaneously. Long wheel life and fast, precise cuts make it essential for manufacturing products for the aerospace, automotive, energy, and medical markets.

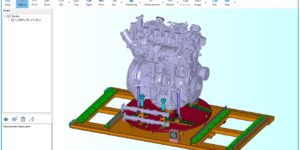

Like Renishaw’s other additive manufacturing (AM) systems, the laser-based AM 400 powder bed fusion printer builds complex components directly from digital CAD files. This came in handy for a Michigan engine developer trying to optimize drone performance.

Featuring application-specific control software that comes preinstalled on a laptop and a small footprint that fits through most standard doorways, the ProtoMAX from OMAX is easy to set up and start using.

MB Metal Technologies’ quick-change base plate for two models of dot peen marking machines comes with round and square jaws to quickly and easily register parts so customers achieve a clean and clear mark.

In addition to providing the longest reach in the high-payload category and featuring a slimmer profile, KUKA’s updated KR Quantec robot offers three software plug-ins to maximize performance, path, and cycle times.

Developed so design and manufacturing teams can quickly and easily import and analyze all file types, Hexagon Manufacturing Intelligence’s updated Workxplore software enhances assembly-related capabilities.

By enabling its Radan CAD/CAM design software to connect seamlessly with the 2021 release of Workplan MES software, Hexagon Manufacturing Intelligence is enabling sheet metal fabricators to establish a complete digital thread from start to finish.

As the North American representative of China’s oldest and largest hydraulic press manufacturer, Greenerd Press & Machine can configure a solution, often incorporating automation, for virtually any application.

Convenience is key when there’s need for a chemical label or OHSA/ANSI sign related to a metal forming, fabrication, or other production process. Create, replace, or update critical safety information quickly and easily with Graphic Products’ DuraLabel Kodiak industrial sign and label printer.

Bel Air Finishing Supply’s two-in-one centrifugal disc finishers save time and money while increasing quality by polishing and deburring. The design produces 10 times the g-force of a vibratory bowl finisher.

Behringer Saws’ safely enclosed HBE Series band saws are equally effective for automatic high-production cutting jobs and one-off cuts. Seven models handle round capacities from 10.2 inches to 41.7 inches.

Advanced Machine & Engineering’s line of AMSAW-WAGNER heavy-duty miter bandsaws can be equipped with linear transducers to verify dimension and adjust miter position accordingly to avoid secondary operations.

Quoting software saves time and money throughout the entire production process if it’s properly integrated with CAD/CAM and manufacturing system software. If it’s not, your team’s doomed to constantly reinvent the wheel.

A robotic system is ‘collaborative’ only if all elements – robot, tooling, workpiece, and work area – meet international safety standards. Depending on application, you may be able to turn a standard industrial robot into a cobot and comply.

MB Metal Technologies’ quick-change base plate for two models of dot peen marking machines comes with round and square jaws to quickly and easily register parts so customers achieve a clean and clear mark.

Walter’s Helitronic Raptor and two-in-one Helitronic Raptor Diamond (grinding/EDM) are aimed at shops that don’t require features like automatic tool support systems or automatic wheel/electrode changers, but want a high degree of flexibility for diverse tool types.

Offering operational flexibility, improved performance, and effortless operation, UNISIG’s next-generation UNE Series deep-hole drilling systems are equally effective in high-volume/low-mix and low-volume/high-mix production environments.

Developed specifically for manufacturers, the SYSPRO enterprise resource planning (ERP) platform automates and integrates business processes to improve production, inventory control, and reporting. Recent enhancements improve security, compliance, traceability, and tax reporting.

An AC inverter drive on the BEX 15 high-speed block spindle from Suhner Industrial Products increases spindle speed to 23,000 rpm at 87 Hz. Two slide-assembly mounting options enable multiple operations.

Used by almost every major CNC machine manufacturer in Germany, the SP ProTwist differential-measurement system distributed by Centric International can be an essential part of any quality management process by simplifying machine tool realignment.

A thousand times more accurate than a typical handheld refractometer, Quaker Houghton’s self-contained continuous concentration monitor is an easy-to-use, low-maintenance way to maintain appropriate metalworking fluid levels.

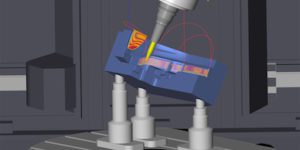

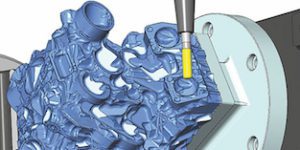

The latest versions of the hyperMILL CAD/CAM software suite from Open Mind Technologies AG encompasses a wide range of user-friendly enhancements and new machining strategies to advance the capabilities for accurate, efficient 3D and 5-axis machining.

NSK America’s electric i-Speed5 spindle system eliminates the need for motor cables or air tubing. Variable-speed system integrates with control system for complete tool changeability.

Distributed in North America by Helios Gear Products, YG Tech’s NEOPS 200 and NEOPS 400 NEO combine an affordable power skiving solution for profitably producing gears with domestic technical and engineering support.

Global Shop Solutions’ Cloud ERP combines maintenance-free software and speed with quick and simple, automatic cloud-based data backups. Files and data are never lost; updates and maintenance are done in-house so users always work with the most up-to-date version.

GF Machining Solutions developed three model machining cells to showcase highly productive turnkey manufacturing systems. They demonstrate everything from simple pairs of machines and robots to mixed-machine configurations for advanced hybridized additive/subtractive machining strategies.

To help develop the next-generation manufacturing workforce, FANUC’s Machining Simulation for Workforce Development software teaches users how to set up and operate three common 5-axis milling machines.

Four models of EMCO’s Maxxturn 45 lathe offer various tailstock, counter spindle, axis, and tool options for producing complex turned and milled parts 4.72 inches (120 mm) long that weigh up to 4.4 pounds (2 kg).

Mastercam 2021 from CNC Software increases machining productivity and lowers overall production costs with improvements in multi-axis capabilities, turning and turning-related applications, and safety.

The latest version of ANCA’s CIMulator3D streamlines tool development with time-saving and user-friendly offline tool path simulation and a hub that automatically analyzes cutting tool design to avoid costly collisions and missed calculations.

A robotic system is ‘collaborative’ only if all elements – robot, tooling, workpiece, and work area – meet international safety standards. Depending on application, you may be able to turn a standard industrial robot into a cobot and comply.

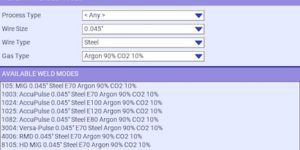

Does your shop use Lincoln Electric or Miller power sources? If so, Yaskawa Motoman’s universal weldcom interface (UWI) enables welders to easily control any process or parameter including amperage, voltage, and wire feed speed.

Yaskawa America’s ArcWorld 6000 pre-engineered workcells featuring Motoman AR-series arc welding robots come with virtually everything you need to get up and running quickly and safely. Available in one-, two-, or three-robot configurations.

Lincoln Electric’s Lincore 420HC-S metal-cored wire for submerged-arc welding (SAW) may be used where higher hardness is required and on work rolls and backup rolls when water spray causes pitting on tool steel deposits.

With loading capacity up to 20,000 pounds, Bluco’s high-tolerance 3D welding tables are hardened to protect against spatter buildup, provide a corrosion-resistant surface, and come with a lifetime warranty.

The Model 317 from Arc Machines features the first orbital welding controller that manages data. The system improves performance and increases production efficiency by gathering and presenting information that enables pipe fabricators to better control the weld.

New technology is making the flap disc a cost-effective and equally effective alternative to grinding wheels in a variety of applications. They’re versatile, lightweight, easier to control, and convenient.

Switching to a modified short-circuit MIG process instead of TIG for the root pass saves time without compromising an operator’s ability to produce high-quality welds that meet code requirements. Your shop will also save money on consumable costs.

A thousand times more accurate than a typical handheld refractometer, Quaker Houghton’s self-contained continuous concentration monitor is an easy-to-use, low-maintenance way to maintain appropriate metalworking fluid levels.

Every ounce of additional productivity rung from each step in the process adds up to significant cost savings over time. From coolant and tooling to programming and scrap management, opportunities to increase efficiency abound.

Big Ass Fans’ Powerfoil D is the only direct-drive overhead fan designed to withstand excessive heat, dust, and other stresses common in fabrication and machining job shops. Diameters: 8 feet to 24 feet.

Vac-U-Max’s recovery system for additive manufacturing extracts unused metal powder from the printing bed and filters it to be reused. The closed system provides a safer work environment because the operator never comes in contact with the powder.

Attach Parker Hannifin’s self-contained SmogHog SHM Machine Mount (MM) onto equipment to collect coolant mists from CNC machining, cold forming, sawing, lathes, and stamping. Easily integrates with machine tool controls for automated operation.

The award-winning ToolMat from Master Magnetics sticks to any flat or curved ferrous metal surface to organize and hold tools and small parts whether you’re working in the shop or on a jobsite.

Gotta move a press brake, machining center, or any other piece of equipment that’s less than 40 feet long? AeroGo’s all-in-one rigging kit ensures safe transfer using compressed air and lightweight overlays.

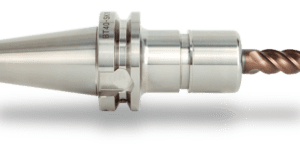

The producer of high-precision tooling solutions introduces a drill for low cutting speeds, dual-purpose milling cutter, jet-through hydraulic chuck line for 5-axis machining, and new EWA fine boring heads and EWE digital boring heads.

An AC inverter drive on the BEX 15 high-speed block spindle from Suhner Industrial Products increases spindle speed to 23,000 rpm at 87 Hz. Two slide-assembly mounting options enable multiple operations.

NSK America’s electric i-Speed5 spindle system eliminates the need for motor cables or air tubing. Variable-speed system integrates with control system for complete tool changeability.

Walter USA’s TC470 Supreme thread former combines a new geometry with more forming edges than comparable formers. Coating and surface treatment increase tool life, productivity, and process reliability in high-volume machining.

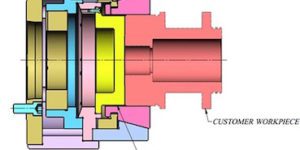

Speedgrip Chuck Company’s standard external collet chuck system combines the benefits of high-precision workholding with in-stock availability to increase precision and productivity.

SMW Autoblok’s CCS adapter increases operator productivity by providing automatic push-off and easy mounting to traditional or custom workholding including 2-jaw chucks, 3-jaw chucks, collet chucks, mandrels, and manual fixtures.

Available in a wide variety of toolholder lengths and diameters for optimal rigidity and clearance, Samchully Workholding’s SK series provide 1 micron runout accuracy as well as three times better runout repeatability and double the gripping force of a comparable ER collet chuck.

Rex-Cut Abrasives is improving the daily grind for customers worldwide by manufacturing three types of Type 27 depressed-center grinding and blending wheels in a 6-inch version.

Rego-Fix reCool systems are an affordable, low-maintenance way to retrofit static or driven tooling systems with internal coolant capabilities, enabling substantial improvements in tool life and productivity.

With the full lineup of Elliott Tool Technologies tools that produce a surface finish of 4 Ra to 8 Ra, Monaghan Tooling Group has the capability to handle virtually any burnishing project.

Mate Precision Tooling supplements its extensive range of standard hardened and precision-ground press brake tools with modified standard and custom designs for special bending challenges.

The U.S. arm of the German firm LACH-Form GmbH & Co. Diamond Engineering KG, Lach Diamond has manufactured polycrystalline diamond (PCD) and cubic boron nitride (CBN) tooling for metalworking since 1973.

Used by almost every major CNC machine manufacturer in Germany, the SP ProTwist differential-measurement system distributed by Centric International can be an essential part of any quality management process by simplifying machine tool realignment.

A thousand times more accurate than a typical handheld refractometer, Quaker Houghton’s self-contained continuous concentration monitor is an easy-to-use, low-maintenance way to maintain appropriate metalworking fluid levels.

Nothing frustrates improvement efforts like software programs that don’t play well together. Brothers Brian and Mitch Olson made sure that didn’t happen when they launched their CNC machining shop by deploying a solution that integrates resource planning and quality management.