February 2020

Digital Issue

The American Society of Civil Engineers gives our bridges, oil-and-gas pipelines, energy grids, and water networks a D+ grade. More than 80% of Americans say repairing and rehabilitating these assets is more important than tariffs, tax reform, health care, and climate change. That’s good news for fabricators and metalworkers who make or supply equipment, assemblies, and/or parts for public construction projects.

Subscribe View Digital IssueA 20% increase in consumable costs reduced an automotive component supplier’s cycle time by 30% and is saving almost $250,000 annually on machine operating costs.

Manufacturers selling to the public sector need a special business acumen to thrive in this market.

How to develop and nurture your own innovation hub.

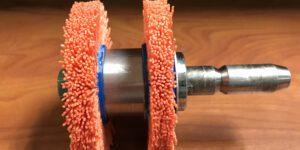

A 20% increase in consumable costs reduced an automotive component supplier’s cycle time by 30% and is saving almost $250,000 annually on machine operating costs.

Every extra part wrung from the same piece of raw and remnant material is money in your pocket. Here’s how to significantly increase earnings.

Step-by-step instructions for perfecting your plasma cutting technique. Similar to how an archeologist can read the history of a canyon wall, an experienced plasma cutting operator can take one look at the surface and tell you what went right, what went wrong, and how to correct your mistakes.

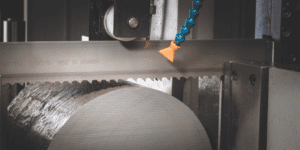

Bandsaw blade strategy helps French firm grow business by more than 50% over the last five to eight years.

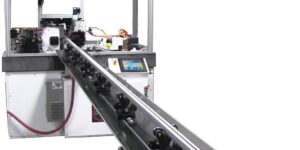

Tormach’s plug-and-play AF50 automatic-feed bandsaw increases profitability by freeing employees to work on more complex jobs than manually prepping stock. Pneumatic clamping system with adjustable soft squeeze safely holds material while hydraulic feed control helps keep blade cutting straight.

Simonds Saw has stopped making Dieband, Blockbuster, and Broadband, IC Enduro, and X51 bandsaw blades and is replacing them with four new bimetal products: the Epic GP (general purpose), two SBX (structural blade extreme) blades, and the SiClone XP, which replaces the X51.

An automatic saw and a tabletop saw from Buehler provide consistency and repeatability in cutting production samples, saving preparation time in the quality control or inspection laboratory. Confidently cut production samples including automotive drive trains, gears, crankshafts, and engine components.

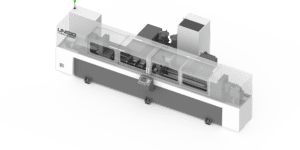

BLM Group USA’s TS72 universal cold sawing CNC system for cutting tubes, bars, and profiles features an axis-control function that enables automated changeover for nonstop, unattended production. Particularly well-suited to small batch sizes, all adjustments and cutting parameters – material, blade type, and tube dimensions – are automatic to eliminate downtime.

Less prone to chipping when used for interrupted cuts and less expensive than carbide, tools made from M42 molybdenum-series high-speed steel alloy with 8% cobalt shorten cycle times by facilitating higher cutting speeds. Featuring a powdered metal M42 edge for harder teeth, Bahco’s 3851 Sandflex Cobra bandsaw blade provides smooth, precise cuts for general-purpose and production-cutting applications.

How to develop and nurture your own innovation hub.

An adaptive-finishing solutions developer combined an ABB robot, Renishaw spindle probe with radio signal transmission, and a twin-pallet system into a system that machines one gear while another is loaded.

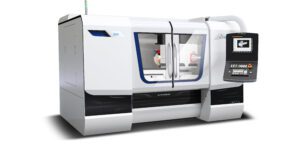

Released by United Grinding North America and Walter Tool, a measurement system for advanced grinding/eroding machines helps manufacturers optimize production of small, high-precision parts by automatically detecting and aligning tools, blanks, and other workpieces.

One of the two spindles on Vollmer’s VHybrid 360 can be used to grind and erode while the other spindle grinds. Manufacturers save time by machining solid carbide or polycrystalline diamond (PCD) drills, milling cutters, and reamers in one set-up.

Milwaukee Tool’s cordless M12 Fuel’s brushless motor is more powerful than pneumatic-powered ¼-in right-angle die grinders.

Hand-held Millhog bevelers from Esco Tool feature an extra-rigid blade-locking system, blades that incorporate a radical chip breaker that transfers heat so cutting fluids aren’t necessary, and a holder that enables the blade to get under the material to pull a thick chip.

A portfolio of 10 Studer machines includes several universal-type models as well as those designed for high production and for radii grinding operations. Control software enables capabilities such as in-process monitoring and the ability to string various cycle times into ISO code.

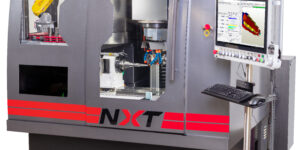

Star SU’s easily configurable NXT 5-axis grinding machine gives manufacturers the ability to run small- and large-diameter wheels to sharpen straight and spiral gash hob designs as well as disk-, shank-, and helical-type shaper cutters, Scudding cutters, and a wide range of round tools.

The Elb-Schliff millGrind BL10 from Precision Surfacing Solutions (PSS): grinding, drilling, and milling in one clamping; deep grinding and, with an optional laser head, deposition welding in the other. A complete machining solution for aerospace manufacturers.

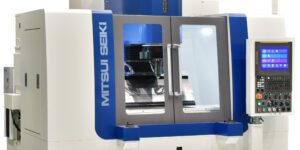

Mitsui Seiki’s new-and-improved J350G grinds small- and large-diameter holes as well as multiple features using a single wheel in a continuous, automatic mode. The machine is 50% smaller than the previous model, giving manufacturers more options for shop floor usage.

A hydraulic chuck combined with a changeable back stop and slotted collet, the Mytec Hydraclamp paves the way for power skiving by enabling users to clamp different diameters and components with one hydraulic chuck.

Apart from milling pins, there haven’t been many solutions for chamfering internal gears – a severe limitation given that roughly half the gears and shafts in a gearbox have interfering contours. Liebherr Gear Technology’s ChamferCut collision gear technology addresses this problem.

Process-improvement company helps customer reduce lead times and costs by configuring an infeed/thrufeed centerless grinding machine with custom software that enabled the customer to vertically integrate.

Chicago Pneumatic’s CP3550 product lineup of 17 compatible finishing models allows perfect matching of applications and tools. Greater torque increases material removal rates and operator comfort while deburring, contouring, chamfering, fettling, removing seam welds, preparing surfaces, cleaning, polishing, and finishing.

Three Tweco-brand welding guns from ESAB offer comfortable high-performance operation when working with large-diameter cored, solid, and aluminum wire and long-reach applications.

We have few more pressing needs than updating roads, bridges, pipelines, and energy grids – a potential goldmine for suppliers of heavy equipment, off-road machinery, assemblies, parts and services used in construction projects. The trick is breaking into the market.

This Kentucky communication tower fabricator got its start a century ago by maintaining water infrastructure assets. Now it’s cashing in on the market for telecommunications infrastructure.

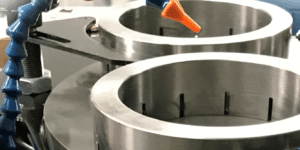

Talk about a high-mix, low-volume operation. American Highway Products’ manhole risers are available in more than 700,000 possible permutations. One software program is getting the jobs done to customers’ wide range of specifications.

Manufacturers selling to the public sector need a special business acumen to thrive in this market.

Every extra part wrung from the same piece of raw and remnant material is money in your pocket. Here’s how to significantly increase earnings.

Three robust, powerful, and portable Fronius USA power sources enable technicians to efficiently repair tractors, combines, and other agricultural equipment. Digital controls make all three intuitive and enable a stable arc and reproducible welding results.

Pulse welding, increased duty cycle, and operator-oriented, easy-to-use interface make the Power MIG 360MP from Lincoln Electric ideal for metal fabrication, maintenance and repair, auto body, and light industrial applications.

Retraining strategies for a robotically automated world.

Metworx Spindle Oil 2 is designed to meet the demanding service requirements of bearings in extremely high-precision, tight-clearance applications.

DiaGrind 535 is recommended by machine manufacturers for gear grinding, hobbing, honing, and cutting.

Products developed by metalworking specialists and chemists for manufacturers of all sizes and volumes.

Environmentally friendly grease provides exceptional mechanical stability, very high load carrying capacity, and excellent water- and moisture-resistance.

Modular filtration solution can be easily expanded and comes with no-leak guarantee.

Solid and indexable cutting tools that increase productivity (and profitability) by more efficiently boring, drilling, reaming, tapping, threading, and finishing.

Newest addition to Walter’s product lineup delivers cost, reliability, and quality benefits by combining thread milling’s advantages with tapping’s efficiency.

Unisig’s feature-rich solution simplifies operation for anyone involved in manufacturing products for the firearms, automotive, medical, energy, defense, and/or aerospace industries.

Drill heads and consumables are compatible and directly interchangeable with CoroDrill 800 deep-hole drilling tools.

New tooth pattern and pitch produce more cuts in less time.

Nano-laminate coating and tool geometry keep chips from causing damage in the final phases of production.

Silent Tools dampening technology and lighter, shorter head enhance performance.

Twist-drilling accessories that last up to 15 times longer than black oxide drill bits.

Methods Machine Tools’ high-speed milling, drilling, tapping, deburring, and chamfering machining center expands capabilities.

Mapal tools for making holes faster and more cost-effectively.

Lightweight reamer meets accuracy, roundness, and surface finish requirements for aluminum motor body boring.

Dual-spindle design provides the flexibility to run two different parts simultaneously.

User-friendly improvements empower operators to write their own programs for Kays Engineering’s Eldorado.

A 20% increase in consumable costs reduced an automotive component supplier’s cycle time by 30% and is saving almost $250,000 annually on machine operating costs.

Step-by-step instructions for perfecting your plasma cutting technique. Similar to how an archeologist can read the history of a canyon wall, an experienced plasma cutting operator can take one look at the surface and tell you what went right, what went wrong, and how to correct your mistakes.

Bandsaw blade strategy helps French firm grow business by more than 50% over the last five to eight years.

Tormach’s plug-and-play AF50 automatic-feed bandsaw increases profitability by freeing employees to work on more complex jobs than manually prepping stock. Pneumatic clamping system with adjustable soft squeeze safely holds material while hydraulic feed control helps keep blade cutting straight.

Simonds Saw has stopped making Dieband, Blockbuster, and Broadband, IC Enduro, and X51 bandsaw blades and is replacing them with four new bimetal products: the Epic GP (general purpose), two SBX (structural blade extreme) blades, and the SiClone XP, which replaces the X51.

How to achieve high-volume, high-quality production for this demanding market.

Camera-equipped cobot enables contract manufacturer to market itself as supplier of high-quality automotive engine subassemblies.

Retraining strategies for a robotically automated world.