February 2021

Digital Issue

Rise of the Machines: Manufacturing Equipment for Post-Pandemic Growth. A challenging year, 2020 created pent-up demand for goods every American needs. Record-low interest rates and the highest personal savings rate since 1975 are expected to drive manufacturing of machinery, assemblies, and parts for agriculture, construction, home-building, and infrastructure.

Subscribe View Digital IssueAs heavy equipment manufacturers gear up for healthy backlogs, a key West Coast supplier is helping customers find reliable and cost-saving replacements for obsolete parts. Meet the former chef-cum-machinist who’s serving up all kinds of new orders via his CAM software.

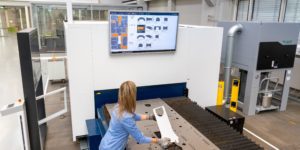

Even the most sophisticated nesting software won’t eliminate the need to manually finish an edge if the job’s not thought through from start to finish. Follow these three best practices to minimize wasted time and material.

A preventative cybersecurity plan helps mitigate damage by outlining next steps once data is compromised. But what about legal fees and public relations expenses to repair potential damage to your company’s reputation?

As heavy equipment manufacturers gear up for healthy backlogs, a key West Coast supplier is helping customers find reliable and cost-saving replacements for obsolete parts. Meet the former chef-cum-machinist who’s serving up all kinds of new orders via his CAM software.

Siemens extends Xcelerator portfolio with enterprise-wide quality management system. Teamcenter Quality provides an all-geographies collaboration platform that also enables engineers to establish their own parameters for excellence.

U.S.-based AGCO makes five brands of agricultural equipment at 40 plants on six continents. To bring order to the potential chaos of model-year changes and new product introductions, the company deployed software for a design anywhere, build anywhere strategy.

Even the most sophisticated nesting software won’t eliminate the need to manually finish an edge if the job’s not thought through from start to finish. Follow these three best practices to minimize wasted time and material.

Fiber laser machines are no longer available just with 4kW and 6kW. As machines become more powerful, fabricators are taking advantage of the ability to cut a wider range of material types and thicknesses, faster cutting and piercing speeds, and better edge quality.

Mazak Optonics’ Optiplex Nexus 3015 Fiber S7 is a 7kW 2D flying optics fiber laser-cutting system with beam-shaping capability that enables operators to select beam size and shape according to material thickness.

There’s a big difference between just cutting fast and achieving impressive throughput. As machines become faster, factories must properly manage downstream handling processes.

The 1300PL has become the most-used machine at Tormach’s facility. The 65-amp plasma cutter cuts 4-foot-by-4-foot sheets of metal up to 1 inch thick and holds up to 750 pounds, and comes with or without a torch.

Soitaab’s two-in-one Dualine performs both low-cost, high-speed plasma cutting and versatile, accurate waterjet cutting. Users can perform both processes on the same workpiece or use the machine solely as a waterjet or solely as a plasma cutter.

With a cutting area of 10 feet by 5 feet, 2 inches and a multiaxis cutting head that automatically removes the taper, Omax’s Maxiem 1530 produces clean, precise cuts in common sheet metal plate sizes with room to spare. The waterjet system includes pump and software.

Fiber lasers provide excellent cutting power and speed, but also produce high volumes of very fine particulate that can quickly overwhelm traditional dust collectors. RoboVent’s plug-and-play Senturion is designed specifically for fiber laser cutting.

Prima Power Laserdyne replaces the Laserdyne 780 with the Laserdyne 811, a high-speed fiber laser for cutting, drilling, DED additive manufacturing, and 2D and 3D welding. Extremely compact rotary and tilt axes laser head comes with two-year, unlimited-hour warranty.

VZ10 and VZ20 laser cutters from MC Machinery feature intuitive CNC control with one-touch teach functions that greatly reduce keystrokes, cutting onboarding time for new operators virtually in half.

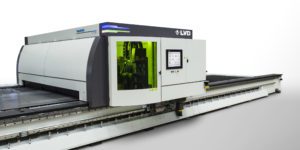

The bed on LVD Strippit’s gantry-style Taurus FL can be expanded in 6.5-foot increments from 39 feet to 131 feet for extra-large sheet metal cutting. Large parts can be cut without repositioning and higher volumes of smaller workpieces can be processed without interruption.

The Torchmate 4510 is Lincoln Electric’s third Torchmate 4000 series product. When equipped with optional FlexCut 125 power supply, the plasma cutter accommodates 5×10 sheet metal up to 1 inch thick.

Available in three models featuring 4-by-4, 4-by-8, and 5-by-10-foot cutting areas, Koike Aronson Ransome’s ShopJet can be shipped on a standard 8-foot truck to fit into any size shop. Get 2,200 pounds of free abrasive with every machine order.

The semi-automatic control system on Kaast’s Plasmasonic switches quickly between plasma and oxy-fuel cutting. Add a pipe cutter or bevel cutter for welding preparation to configure an all-in-one machine that cuts metal sheets and pipes, chamfers, marks, and perforates.

Hypertherm’s MAXPRO200 operates with air, oxygen, or nitrogen plasma gas, combining fast cutting speeds and quick process changes to maximize productivity. LongLife technology significantly increases consumable life to lower cost per part.

German Machine Tools of America (GMTA) buttresses its line of machines for U.S. power train manufacturing by representing Stiefelmayer GmbH fiber and diode laser machines for cutting and hardening. The machines are particularly well-suited for the thin components required for electric vehicles.

Seattle-based Fairmont Machinery is importing, distributing, and servicing Power-Tech’s Eagle laser cutting systems. The Polish machine tool builder’s products are available with 6, 12, 15, and 20kW of power.

ESAB’s Hydrocut HDX combines waterjet’s precision with plasma’s speed in a work area that’s 18 feet wide and 56 feet long. Combining technologies cuts per-part cost in half and enhances workplace safety by reducing handling needs.

With 15kW of power, Bystronic’s ByStar Fiber 3015 and ByStar Fiber 4020 cut steel, aluminum, and stainless steel from 20 gauge to 1.5 inch thick as well as brass and copper up to 0.750 inch.

Ideal for Industry 4.0, the fully automated TruLaser Center 7030 from TRUMPF works autonomously over long periods, without any operator intervention for programming all the way to sorted and stacked finished parts. It eliminates collisions involving tilted parts, refinishing work on microjoints, spatter on the undersides of components, and excessive programming work.

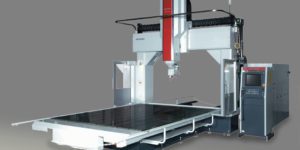

Agricultural and construction equipment uses many of the same components you see in cars, but they’re a lot bigger, a lot heavier, and generate a lot more swarf. Machining engine blocks and gearbox housings requires a different type of machine tool.

In addition to a wider screen that allows for a split view, Gen 3 drives for Heidenhain’s TNC 640 control system allow for jig grinding and trochoidal milling capabilities on smaller machine tools.

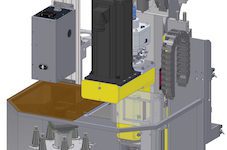

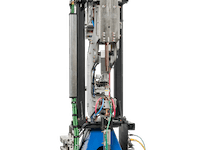

A heavy equipment manufacturer is using a 6-axis robotic arm equipped with a drilling spindle to very precisely make holes in structural steel up to 1 inch thick. The solution is one-third the cost of traditional drilling but performs many other applications and requires just one operator.

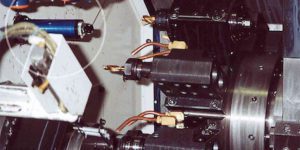

In addition to Swiss-style speed and accuracy, Tsugami’s SS327-III-5AX cuts contoured shapes using a servo-driven B-axis that turns the CNC lathe into a multitasking turning center that can drill, tap, and end mill any angle.

Tormach’s 8L lathe provides operators with everything they need to face, turn, bore, groove, and thread 1-inch-diameter materials including stainless steel and titanium. They can add a 3- or 4-jaw chuck to cut the stock for workpieces up to 8 inches in diameter.

Designed around the BTA deep-hole drilling process in cylindrical parts, Sunnen’s heavy-duty SHDD Series performs similar processes including counterboring, pull boring, trepanning, bottom forming, and skiving/roller burnishing.

Palmgren offers a deluxe model of its vibration-free vertical-turret mill that provides the same quality and durability but with digital features including a two-axis readout.

Featuring a large machining area envelope and short tool spindle, the highly efficient Nakamura-Tome JX-250 mill/turn machining center from Methods Machine Tools allows maximum part length and performs left and right simultaneous machining.

Mazak’s QT-Ez Series turning centers introduce a new machine with new control technology to the North American market. Four configurations offer a wide range of size, automation, and programming options in an easier-to-operate-and-maintain machine.

Like the company’s other combination mills, Kent Industrial’s KTM-VH500EVS enhances efficiency by enabling operators to perform horizontal and vertical milling with the same machine. Operators can make heavier, deeper cuts without extra setup time.

The geared drive system and electronic variable speed (EVS) motor on JPW Industries’ 20-inch Powermatic PM2820EVS enable the drill press to easily pre-drill and drill for assembly, spindle sanding, fixturing, and countersinking.

The Auto Drill 30 station for ESAB’s Suprarex HDX and Numorex cutting machines increases productivity by combining multiple processes. Operators can produce finished, or nearly finished, parts using one automation system.

Datron Dynamic’s compact MXCube was designed from the ground up as a high-speed milling solution that improves and accelerates workflow through simple and clean operation that virtually eliminates post-processing.

U.S.-based ACS Industries had a lock on the market for standard attachments – buckets, forks, blades, etc. – for construction equipment, but needed to cost-effectively fabricate specialized implements for related markets. Six-axis robotic welding clinched $1.5 million in new business while lowering labor costs 60%.

ESAB’s Savage A40 PAPR has a two-stage replaceable filtration cartridge that meets NIOSH certification and removes 99.9 percent of airborne particles. Providing comfort, performance and value, this helmet will be available at the end of January 2021.

Miller Electric’s Metal Matrix and Gear Box helmets have the graphical identity that resonate with welders while giving them the protection they need. The Digital Elite and Classic Series helmets have built-in technology that automatically activates for optimal optical safety.

Weldcote introduces high-definition technology for passive-style welding helmets designed to reduce eye fatigue. Offering a view area of 5.15 square inches, the filters come in four choices of shade.

Slag is more than a bothersome byproduct. It plays an important role in ensuring good weld quality, and the various slag systems also impact a wire’s welding characteristics.

Featuring an all-aluminum power distribution panel, lift eyes, fork pockets, and heavy-duty casters, Trystar’s 9 kVA weld rack provides an integrated and portable solution for welding applications.

Mix and match Flexturs welding tables, Gridlok mount systems, and fixture accessories as needed to increase efficiency by eliminating costly and time-consuming jigs. The wheeled workstations are quickly and easily reconfigured and relocated as needed.

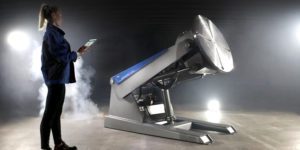

Pemamek’s PEMA Skymaster PRO welding positioner enables the operator to preprogram work cycles and handling positions for workpieces weighing up to 39 tons. The control dashboard is managed via any Wi-Fi device.

CenterLine introduces two SoftMount inverted-nut gun configurations for a high-speed fastener welding system that streamlines the process from operator load to finished part, providing higher throughput than standard welding solutions.

The seat, backrest, and arms of the American-made Vyper Chair are adjustable. Additional features such as a footrest increase welder and fabricator comfort and productivity by correcting posture and reducing back strain.

Zoneworks EZ Employee Separation Barriers from Rite-Hite protect employees who can’t work more than 6 feet apart. Lightweight panels made of clear PVC are easily wiped down to further mitigate exposure to airborne viruses.

Palmer Wahl’s portable HSB50 Heat Spy can be used to verify the reading of hand-held infrared thermometers and thermal cameras and/or provide greater-accuracy measurements for thermal imaging temperature scanning systems.

MicroCare’s Stereze products are formulated using a high-purity alcohol-based solution which is focused on high-performance cleaning. They’re safe to use on metal tools and machinery and stand up to rigorous scrubbing on rough surfaces.

According to the U.S. Centers for Disease Control and Prevention, back pain is the top work-related health problem. The Apex from HeroWear minimizes the potential for injury by making loads 50 pounds lighter when an employee lifts and bends.

ANSI- and CSA-rated for high impact, Pyramex Safety’s Carhartt Braswell Readers are available in three magnification levels. Hard-wearing frame and lens are made from virtually shatter-resistant polycarbonate.

The lightweight SmartCut BKCR2403 glove from Brass Knuckle Safety Products provides abrasion- and cut-resistance protection for employees performing metal assembly, fabrication, and manufacturing work requiring fine motor dexterity and tactile sensitivity.

Fiber lasers provide excellent cutting power and speed, but also produce high volumes of very fine particulate that can quickly overwhelm traditional dust collectors. RoboVent’s plug-and-play Senturion is designed specifically for fiber laser cutting.

It’s time for machine tool builders and machining companies to shelf the long-standing ISO 1940-1 standard in favor of ISO 16084:2017. Not only is balancing tools rarely necessary, it can also be risky.

Weldcote’s A-Prime Plus line of cutting wheels lasts longer because they’re manufactured via a multistep granulation process that evenly distributes each individually coated aluminum oxide grain.

Shur-Brite finishing wheels from Superior Abrasives produce a satin finish without the visible transition lines often caused by traditional flap brushes. Their seamless design ensures conformability by providing superior cushioning at low speeds.

Sugino’s Superoll burnishing tools provide 0.1-to-0.8-micron finishing in one pass. They integrate into machining centers to improve productivity by eliminating secondary processes, such as grinding and honing, without removing additional material.

The entire working section of Rex-Cut Abrasives’ Aluminator grinding wheel can be used without sacrificing productivity or finish. Its cotton fiber breaks down to continually expose new grit, providing consistent metal removal for the wheel’s entire life.

The distinctive pink abrasive grain makes Palmgren’s mounted stones exceptionally durable while providing cooler cutting.

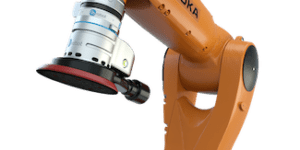

OnRobot’s random orbital sander is an out-of-the-box automated sanding and polishing solution that works with virtually any collaborative robot (cobot) brand. Brushless electric motor costs less than traditional pneumatically powered sanding systems.

The core of Norton Winter Aeon electroplated grinding wheels from Saint-Gobain Abrasives can be re-plated with new diamond or cBN grain in a continuous re-plating cycle for increased efficiency and long life.

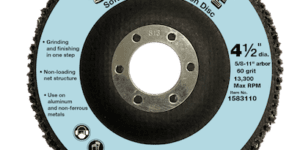

Lawson Products’ nonloading Blue-Kote flap disc incorporates aluminum oxide grain for excellent grinding and smooth, scratch-free finishing. The long-lasting disc reduces costs by saving process time and eliminating the need for product changeover.

All an operator needs to change the grinding head on the BG448 from Kalamazoo Industries from vertical to horizontal (or any position between) is an Allen wrench. Insert wrench in holes on the contact wheel, loosen the socket head cap screws slightly, tilt head, and re-secure.

To enable high-volume gear production, Horn USA will develop a carbide milling tool and machining program to produce defined chamfers based on material and gear tooth geometry. The service quickly pays for itself and doesn’t require special workholding.

Dynabrade’s replacement pads fit the company’s Dynorbital Extreme and Dynorbital-Spirit random orbital sanders as well as most competitive brands. Co-branding and private label opportunities are available.

ATI Industrial Automation’s electric RCE-710 has built-in radial compliance with single-axis lockout to facilitate robot programming. Available as a complete end-effector package, the robust tool handles a wide range of material-removal tasks.

Mix and match Flexturs welding tables, Gridlok mount systems, and fixture accessories as needed to increase efficiency by eliminating costly and time-consuming jigs. The wheeled workstations are quickly and easily reconfigured and relocated as needed.

Reaching tough weldments on a homemade fixture can force welders to climb ladders, crawl around on the floor, manually move heavy parts, or engineer other risky access solutions. Bluco’s modular fixturing provides the flexibility they need to safely solve difficult welding challenges.

Omega Tool Measuring Machines adds the Vue with 145x magnification and Vue Lite with 95x magnification to its portfolio of cutting-tool presetting and inspection systems.

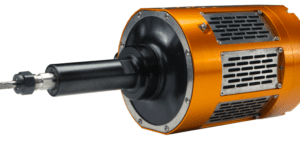

Nordmann provides systems for tool monitoring and process control for all types of metal cutting operations. The SEM-Modul-e can be used to monitor tools, processes and machines.

The Artis GEMVM from Marposs is a stand-alone spindle-monitoring module that aids in predictive maintenance. Runs on Windows machine control panels or Siemens Linux systems and integrates with Marposs’ Genior Modular monitoring system.

Capable of measuring 400 millimeters of travel on both axes, Hoffmann Group’s Garant VG Basic features an intuitive program that makes the cutting-tool presetter easy to set up and operate. Use it at the machine or a production island.

In addition to a wider screen that allows for a split view, Gen 3 drives for Heidenhain’s TNC 640 control system allow for jig grinding and trochoidal milling capabilities on smaller machine tools.

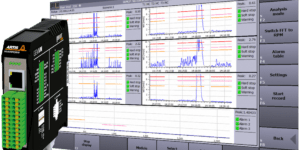

Caron Engineering’s browser-based TMAC 3.0 enables real-time monitoring and system control from any network-connected device for any machine tool brand. It’s ideal for unattended CNC machining because no operator intervention is required.

Allora International’s PCS-100 sensor kicks in only when a drill, tap, reamer, or end mill breaks, not when chips are accumulating; and ignores common tool-to-tool diameter differences. Speeds exceed 80 cycles/minute to keep up with the fastest machines.

One of manufacturing’s biggest challenges is filling the knowledge gap left by skilled employees who retire. Intelligent machine control (IMC) increases throughput regardless of who’s operating measurement and production equipment by removing the potential for human error.

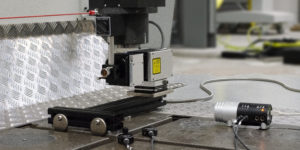

Long-range measurement functionality in Carto 4.2 operating software enables Renishaw’s XM-60 multiaxis calibrator to capture and analyze data from a linear axis regardless of how long it is. The program also facilitates Heidenhain linear compensation.