February 2022

Digital Issue

Finding Workers: More Than a Help-Wanted Ad. The manufacturing sector faces a dichotomy where output continues to surge while record numbers of jobs go unfilled. A challenge in attracting workers is getting the word out about the opportunities, advantages, and the prospects for career growth. Modern manufacturing jobs are built on technology, which is something those not associated with manufacturing may not be aware of. To attract — and retain workers — manufacturers are encouraged to invite people in to show them modern manufacturing processes. Reach out to underrepresented communities, military veterans, educators, guidance counselors, parents, and students themselves. Keep in mind the digital savvy nature of the people you are attracting: provide online courses and virtual reality training, as examples, which upskill people faster. Share how automation augments a manufacturing worker's experiences. And, have staff share their rewarding experiences and opportunities for upward mobility.

Subscribe View Digital IssueWelders want a cleaner, low fume environment that keeps them more productive, comfortable and safer. Read on for tips on how best to clear the air.

Our individual health, and employee retention efforts are improved with new technology to clean the air in our facilities.

Monitor and evaluate tool life to remain competitive and reduce waste.

Remarkable things happen when manufacturers open the shop doors and invite people in, which includes filling the workforce pipeline.

Attracting and retaining workers can be a challenging task. One place to start is by engaging students and their parents.

Fabricators can select from diverse and extensive lines of equipment to meet the exacting needs of their customers.

CAMBRIO aims to help shape the future of manufacturing and assist its customers in meeting changes head on. CAMBRIO’s brands, including SigmaNEST, comprise a diverse set of smart end-to-end design and manufacturing software solutions. The acquisition by Sandvik allows CAMBRIO to collaborate with the Sandvik family and put those resources to work for the benefit of customers.

Innovations in press technology are pushing down the barriers for new operators to learn metal forming and making the process of training new operators safer and more productive.

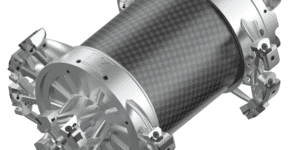

Additive manufacturing is producing complex, high performance tooling and components that go the distance in the most demanding applications.

Innovations in automation and robotics products and solutions ensure your shop’s processes run smoothly.

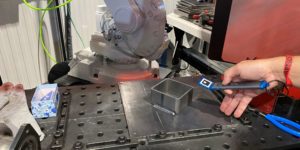

Industry 4.0 advancements increase productivity and performance by reducing the margin of error, providing insights into your machining operation, and streamlining and simplifying essential processes.

Welders want a cleaner, low fume environment that keeps them more productive, comfortable and safer. Read on for tips on how best to clear the air.

Full turnkey, flexible, and customizable products and solutions are available to save your shop time and money.

Our individual health, and employee retention efforts are improved with new technology to clean the air in our facilities.

Modular welding cells and an intuitive programming interface simplify the adoption of robotic welding for SMEs.

Utilizing the proper wire brush for your job goes a long way toward optimizing brush performance, getting the job done faster and in a safer manner.

Smarter machines and weld data monitoring offer more capabilities, which makes it easier to train welders and help them reduce mistakes.

Cleaning is an essential step toward achieving a quality surface finish. Vapor degreasing offers long-term flexibility and adapts to specific requirements, among other advantages.

Industry professionals share insights and products to assist in fostering zero injuries in your shop.

Long tool life is a critical component toward ensuring your shop remains competitive.

Monitor and evaluate tool life to remain competitive and reduce waste.

You don’t have to be an expert in measurement and inspection thanks to products that make balancing your tools fast and easy

Employers may be able to search for people who may be less experienced in manufacturing but have good mechanical and computer skills. Digital savvy youth can be trained in one or a handful of roles as required.

Software innovations add even more detail and automation to non-destructive CT inspection, which makes material and part performance evaluations easier, among other advantages.