January 2013

Let’s all give thanks for the entreprenuerial spirit that drives our industry. And with that thanks, just in case, here are some nuggets that might save the corporate neck of some entrepreneurs.

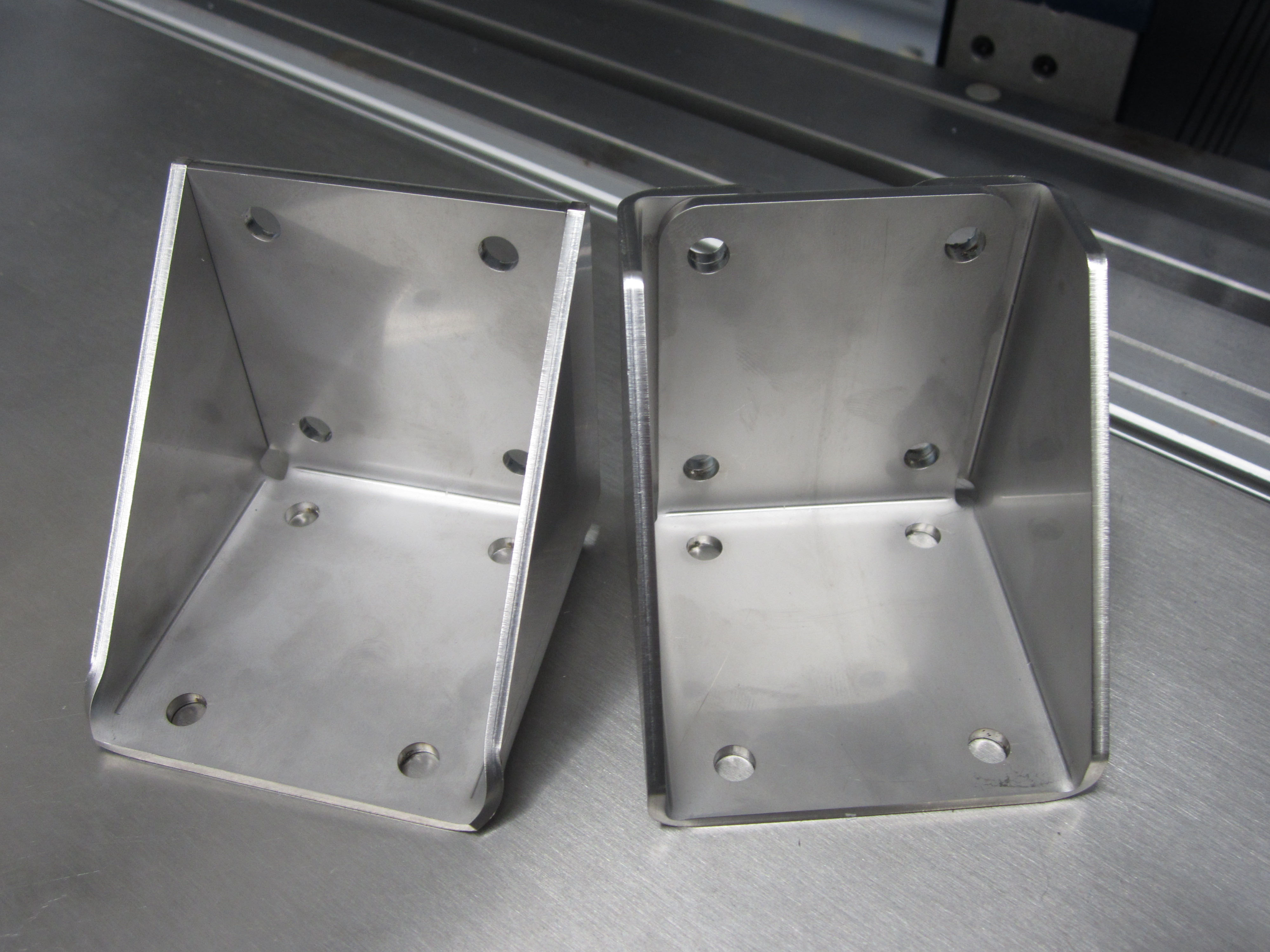

Revisiting the steps used to make a common bracket can eliminate the need for welding, make the part even easier to produce, and demonstrate how the smallest improvements in part design can reap major benefits in time and money.

The absence of injuries does not denote the presence of safety. In fact, a series of near misses indicates a problem in your safety management. Here are some important safety factors that identify whether your shop is at heightened risk of a serious injury or fatality.

Michael Mahfet is the vice president and general manager of ABB Robotics, North America, which designs and manufactures industrial robots and modular manufacturing systems used in precision metal cutting, metal forming, welding and other metalworking applications.

Insights for Strategy and Planning: Fabrication and metalworking executives share their personal assessments of the current state of business, the market sectors they see with the most business activity, the critical issues and major trends that are developing within the industry, and how advancements in technology are changing the way companies will compete during the coming year.

An outline of the overall technology and trends, critical issues and industry insights for the industrial metal forming and fabrication sector.

Rolf Biekert is the president and chief executive officer of TRUMPF Inc., which manufactures precision sheet metal fabrication equipment and industrial laser systems for industrial markets throughout North America.

Bill Isaac is the vice president of MC Machinery Systems, Inc., a wholly-owned subsidiary of Mitsubishi Corporation that imports, sells and supports electrical discharge machines, laser and waterjet cutting systems, press brakes and milling machines.

Bob St. Aubin is the president of Bystronic Inc., which manufactures laser cutting systems, waterjet cutting systems and press brakes for the precision processing of sheet metal.

Dr. John Cheung is the chief executive officer of OMAX® Corporation, which designs and manufactures abrasive waterjets for the precision cutting of metals, composites, glass, ceramics and other materials.

Revisiting the steps used to make a common bracket can eliminate the need for welding, make the part even easier to produce, and demonstrate how the smallest improvements in part design can reap major benefits in time and money.

An outline of the overall technology trends, critical issues and industry insights for the industrial metal cutting sector.

Brian Papke is the president of Mazak Corporation, which designs and manufactures CNC turning centers, multitasking lathes, vertical and horizontal machining centers for the aerospace, automotive, electronics and construction industries.

Don Lane is the president and chief executive officer of Makino, Inc., which designs and manufactures horizontal and vertical machining centers, electrical discharge machines and production systems for the die/mold, aerospace and automotive industries in North and South America.

Rajas Sukthankar is the director of sales for motion control at Siemens Industry, Inc., which designs and manufactures CNC controllers, software and other motion control solutions used in precision metal cutting, metal forming and other metalworking applications.

Michael Mahfet is the vice president and general manager of ABB Robotics, North America, which designs and manufactures industrial robots and modular manufacturing systems used in precision metal cutting, metal forming, welding and other metalworking applications.

Greg Champion is the vice president of sales and marketing at Goellner, Inc., the holding company for Advanced Machine & Engineering Co., which manufactures and distributes precision machine tool components and metal cutting solutions, and Hennig, Inc., which builds machine protection and chip/coolant filtration systems used on machine tools.

Let’s all give thanks for the entreprenuerial spirit that drives our industry. And with that thanks, just in case, here are some nuggets that might save the corporate neck of some entrepreneurs.

Retrofitting those old knee mills and lathes is now faster, easier and less expensive than ever, plus you get other big-time operating advantages.

Any process is most likely to fail at its weakest point. The post processor is often the weakest link in 5-axis machining even though it might not get high visibility during a machine tool purchase. Here are some reasons why it is reckless to invest capital in machinery and software without having a clear plan for post processor implementation.

An outline of the overall technology trends, critical issues and industry insights for the industrial welding sector.

Mike Weller is the president of Miller Electric Manufacturing Co. and ITW Welding North America, which manufactures arc welding and cutting equipment for manufacturing, fabrication, construction, aviation, motorsports, education, agriculture and marine applications.

Lesson Learned: This analysis shows how one must be careful of getting locked into welding a certain way only because that’s the way it has always been done.

The absence of injuries does not denote the presence of safety. In fact, a series of near misses indicates a problem in your safety management. Here are some important safety factors that identify whether your shop is at heightened risk of a serious injury or fatality.