January 2015

State of the Industry: The sleeping giant has been awakened. As U.S. manufacturing enters into a vibrant new era where industry forces are disrupting the status quo, the eighth largest economy in the world should grow stronger than ever before.

State of the Industry: As we enter the New Year, strong market conditions continue in the automotive, aerospace, energy, and medical industries, where leading original equipment manufacturers and their suppliers are looking for better ways to improve productivity.

State of the Industry: Manufacturing is seeing rapid, exciting change in ways never before imagined – and it’s just the beginning for what’s to come.

The Scantool Centerless 75CGC belt grinder with coolant from CML USA is ideal for removing rust and creating a highly polished or brushed surface finish on diameters ranging from .75 in up to 3 in.

State of the Industry: The sleeping giant has been awakened. As U.S. manufacturing enters into a vibrant new era where industry forces are disrupting the status quo, the eighth largest economy in the world should grow stronger than ever before.

State of the Industry: As we enter the New Year, strong market conditions continue in the automotive, aerospace, energy, and medical industries, where leading original equipment manufacturers and their suppliers are looking for better ways to improve productivity.

State of the Industry: Manufacturing is seeing rapid, exciting change in ways never before imagined – and it’s just the beginning for what’s to come.

State of the Industry: Manufacturers, both small and large, are about to adopt Cloud software in great numbers as configurable Cloud ERP pushes the competitive drive toward operational excellence.

To hit those very small flange length tolerances on our prints, we need to master that material stretch. This means we need to understand not just the material, but also how the press brake tooling being used to perform the bend will change the amount of stretch and impact the size of the blank.

You should devote almost as much attention to documenting the deal as you did conducting the bid process to cover the many things that can go wrong in the time between making the down payment and final acceptance. Here’s why.

Burrs can now be quickly and easily cleaned from the ends of unconventional configurations of steel, aluminum and non-ferrous metal pipes and tubes used for automotive parts.

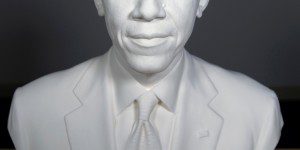

A system called the “mobile light stage” was used to record a digital model of the president and then create the 3D portrait.

The enhanced 8-Mark-II saw from Marvel uses a 5 hp motor controlled with a variable frequency drive.

State of the Industry: The sleeping giant has been awakened. As U.S. manufacturing enters into a vibrant new era where industry forces are disrupting the status quo, the eighth largest economy in the world should grow stronger than ever before.

State of the Industry: As we enter the New Year, strong market conditions continue in the automotive, aerospace, energy, and medical industries, where leading original equipment manufacturers and their suppliers are looking for better ways to improve productivity.

State of the Industry: Manufacturing is seeing rapid, exciting change in ways never before imagined – and it’s just the beginning for what’s to come.

State of the Industry: Manufacturers, both small and large, are about to adopt Cloud software in great numbers as configurable Cloud ERP pushes the competitive drive toward operational excellence.

If the manufacturer is able to move past the sticker price and examine the dollars spent making the part, or the cost per part, a multitude of qualities can factor into the machine tool’s return on investment. Here are some reasons why a less expensive piece of equipment is not always the obvious choice.

You should devote almost as much attention to documenting the deal as you did conducting the bid process to cover the many things that can go wrong in the time between making the down payment and final acceptance. Here’s why.

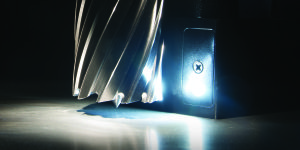

This LED light from Hougen lights the pilot point when drilling in low light, and in brighter conditions it counteracts shadows from the light.

GAE Series CNC Angular Cylindrical Grinders from Shigiya are ideal for heavy grinding precision and, when combined with an angle head type wheelhead, perform face grinding with ease.

Take a look at how PC-based control technology is turning visionary Industry 4.0 concepts into profitable “smart factories” through the use of Google Glass in automation, all-in-one robot and machine tool control, and standard OPC UA connectivity.

Integrating the communication between these advanced CNC machine tools can open a new competitive advantage in vertical, horizontal and universal machining operations.

State of the Industry: Manufacturing has always been the backbone of the U.S. economy and now, with lower cost and more abundant energy sources at our disposal, the future looks brighter than ever as new technologies come to market to address several pervasive influences in our industry.

State of the Industry: Consider the possible business implications these market trends carry as you plan for the coming year.

Numerous benefits can be gained from improved fuel efficiency and reduced noise when using new welder/generators with speed-regulating technology.

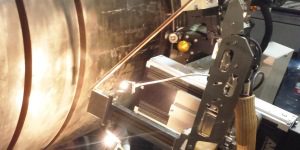

This new line of horizontal and vertical welding lathes features PLC-based controls that are ideal for remanufacturing slab caster rolls, shell rolls, zinc pot rolls, mandrel bars and more.

For 25 years the M207 from Arc Machines has been the workhorse system of choice for leading mechanical contractors. But it now appears the M217WDR will likely be its worthy successor.

Utilizing tools that provide more cost-effective and efficient recruiting, screening and weld training will aid companies in finding the right welding talent and reducing training timelines, placing qualified welding operators on the production floor in a timely manner.

The welding industry is not really facing a skills gap. We’re facing a knowledge gap – and by adopting a new approach to recruitment, screening and training, our industry can bridge this gap and replenish our shop floors with qualified, educated welders.

The Aristo® Mig 4004i Pulse power source from ESAB is ideal for manufacturing trucks, buses, trailers, off-highway equipment, trains and railway rolling stock, wind turbine towers, structural steelwork, shipbuilding/offshore, and general industrial fabrication.

Power or rewind SWCR Series reels from Hannay Reels are ideal for use with a single conductor electrode cable or grounding lead.

The CFM VHO200 sump pump vacuum from Nilfisk collects, recycles, separates and discharges gallons of chips, cuttings, lubricants and other liquids in just minutes.

CECOR Sump Shark sump cleaners separate metalworking fluids from the solids being vacuumed so the fluids can be recycled.

This innovative compressed air system is a game changer that reduces energy consumption by a staggering 50 percent on average, compared to idling compressors.

The GA 7-37 VSD+ compressor from Atlas Copco reduces energy consumption by a staggering 50 percent on average, compared to idling compressors.

The Comfort Weld™ Anti-Fatigue Welding Mat from Aleco guards against sparks and hot metal and enables welders to stand comfortably for long periods of time with no pain and fatigue.

The gearing of the LinA push-type unit from BENZ converts the rotational movement of the drive into a linear movement of the chisel to create geometric forms up to 35 mm long on machining centers with the axial push-type unit.

State of the Industry: Manufacturing is seeing rapid, exciting change in ways never before imagined – and it’s just the beginning for what’s to come.

These advanced laser cutting and inspection systems enable cutting tool manufacturers to achieve results that were formerly unattainable.

These advanced cutting tools bring new attention to boring, reaming, threading and milling different materials that range from 4140 steel to grey cast iron to aluminum 7075.

Investing in better consumables that significantly cut time and manpower costs is smart business. Selecting the right abrasive technology for specific applications to achieve speed and precision is one way to maintain your bottom line.

Power Mill Solid Carbide Endmills from Haimer use endmill geometries that are ideal for chatter free high end machining and extremely smooth surfaces for the best possible chip evacuation.

By cutting through boron steel and associated welds, the new class of impact hammers and chisels cuts tear down cycle times up to 75 percent and reduces repetitive stress injuries over 50 percent.