January 2018

Digital Issue

As total motor carrier revenue follows the road to becoming a trillion-dollar industry, we examine how the growing demand for freight transportation offers great business opportunities for fabricators that supply parts and assemblies to the heavy-haul trucking industry.

Subscribe View Digital IssueThe stamping industry will be alive and strong in 2018, shifting to meet the changing needs of the marketplace and their customers. Here are some insights into how the industry is evolving to remain competitive and healthy.

Light industrial CNC plasma cutting options now make it possible for small home-based businesses and hobbyists to complete amazing jobs that were almost impossible a decade ago. These new plasma cutting systems can provide great performance at even better prices, but make sure they fit your needs before getting started so that you aren’t disappointed.

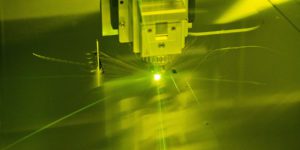

Though it is often overlooked by equipment users, one of the most critical factors to consistent laser cutting quality is the proper maintenance of the worktable where the cutting process takes place.

The small footprint RSSA-6 is a custom precise shot peening machine from Guyson that meets AMS-2431/ 2E specifications.

These load-bearing shaped tubes on the Audi Q5 are expanded during hydroforming by Vari-Form to include in-die hole punching, all while maintaining very tight tolerances and specified final surface characteristics for a flawless final assembly.

Growing demand for freight transportation offers great business opportunities for fabricators that supply parts and assemblies to the heavy-haul trucking industry.

Though it is often overlooked by equipment users, one of the most critical factors to consistent laser cutting quality is the proper maintenance of the worktable where the cutting process takes place.

Shop owners and decision makers are feeling more comfortable with the economic climate and are more willing to make capital investments in new machinery that adds capacity to their operations. Here are some insights into the equipment they will need.

Stamping dies feature complex geometries with tight tolerances that can take time to produce due to tooling changes, breakages, or programming challenges. This machine shop shares some insights on how they use powerful CAD/CAM software for easier and more functional programming that minimizes time and costs.

The Dynafile abrasive belt machine from Dynabrade is ideal for light corner weld removal, blending of welds, grinding, deburring, blending and finishing normally inaccessible areas on metal, plastic, fiberglass and other composites.

A basketball hoop was created with hyperMILL CAM software from OPEN MIND on a GROB G350 5-axis machining center using conical ball barrel cutters from OSG.

The average tractor-trailer goes less than seven miles on a gallon of fuel. Diesel-powered truck manufacturers are trying to address that by changing many aspects of vehicle design to improve fuel efficiency, lower emissions and sell more trucks – great opportunities for the machine shops that supply parts and assemblies to this business.

The flexibility, accuracy and speed of universal cylindrical grinding built this job shop a reputation for fast deliveries, superior part finishes and versatile machining of high quality prototypes and critical automotive and trucking parts, and quick turnarounds of fixtures to reverse engineer worn/broken parts.

A stronger and faster comeback for flatbed trailers, along with increases in other trailer segments, offers more business opportunities for commercial vehicle trailer manufacturers, along with fabricators that supply parts and assemblies to the heavy-haul trucking industry.

An operation that switches to submerged arc welding can double or even triple productivity and make more efficient use of labor time – outcomes that help justify the initial equipment investment.

Light industrial CNC plasma cutting options now make it possible for small home-based businesses and hobbyists to complete amazing jobs that were almost impossible a decade ago. These new plasma cutting systems can provide great performance at even better prices, but make sure they fit your needs before getting started so that you aren’t disappointed.

Here are some insights into proper storage and handling of stick electrodes, solid wires and tubular wires (flux-cored and metal-cored) that can help you achieve the best welding performance, minimize downtime and reduce operating costs.

The Lube-free Lambda Chain from U.S. Tsubaki Power Transmission uses NSF-H1 high temperature, food-grade lubricant impregnated into the bushings for improved chain performance and extended wear life.

Though traditional coatings help prevent spatter and slag buildup that plagues welding, laser cutting and plasma cutting operations, they must be re-applied frequently, which adds to labor costs. To significantly reduce the cost impact of slag and spatter buildup, engineered ceramic coating technology is now the way to go.

Stamping dies feature complex geometries with tight tolerances that can take time to produce due to tooling changes, breakages, or programming challenges. This machine shop shares some insights on how they use powerful CAD/CAM software for easier and more functional programming that minimizes time and costs.

In the chase to help carriers move more freight with better fuel efficiency and less emissions, shops that supply them with parts, assemblies and final equipment will pursue the heart of faster and more accurate processes, shorter cycle times and lower operating costs: new tooling and workholding.

The stamping industry will be alive and strong in 2018, shifting to meet the changing needs of the marketplace and their customers. Here are some insights into how the industry is evolving to remain competitive and healthy.

Did you realize that the G2.5 balance specification in ISO 1940-1 is no longer practical, technically possible or economically feasible in today’s advanced manufacturing environment? Here’s the good news: A new standard is now being developed that applies to all of today’s relevant variables for safe and productive machining. Say hello to ISO 16084.

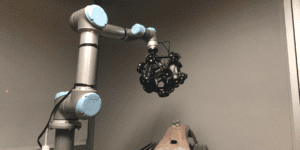

Universal Robots offers the Universal Metrology Automation system from 3D Infotech powered by Streamline on a UR5 cobot mated to a Creaform MetraSCAN-R laser scanner for flexible inspection of complex aerospace, automotive, consumer and medical device parts.

The turnkey Robotic Inspection System from ABB-NUB3D is ideal for automotive original equipment manufacturers, aerospace companies and other metalworking sectors.

Quality and characteristics of the product material, fitting tolerances, and overall cleanliness of a surface or particle load all contribute to the measurable technical cleanliness of automotive components, an integral factor in upholding rigorous requirements on emission reduction, fuel efficiency, long-term durability and regulatory standards.