January 2021

Digital Issue

Seize the New Day: 2021 Industry Outlook. Digital technologies are coming of age and global supply chains are bringing work back to the U.S. We ask industry experts to predict the opportunities that await our audience over the coming year.

Subscribe View Digital IssueEveryone’s ready for a fresh start this year, but one company isn’t leaving 2021 outcomes to chance. A dynamic new marketing approach for 120-year-old Jarvis Cutting Tools included a logo redesign, a bold undertaking led by an industry outsider.

Although 3D metal printing is becoming more popular, finishing remains a challenging and arduous task. Understanding how post-processing works and how to measure results will help you optimize this crucial step.

Impediments to fully optimized band sawing can be broken into three broad categories: teeth problems, blade problems, and cutting problems. These troubleshooting tips will help operators of all experience levels work as efficiently as possible.

Everyone’s ready for a fresh start this year, but one company isn’t leaving 2021 outcomes to chance. A dynamic new marketing approach for 120-year-old Jarvis Cutting Tools included a logo redesign, a bold undertaking led by an industry outsider.

National Association of Manufacturers Chief Economist Chad Moutray explains how pandemic-driven disruption is influencing digitization and data sharing, re- and near-shoring, and hiring.

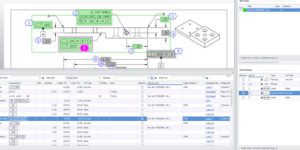

When coupled with an MPiec controller, machine tool builders and experienced CNC programmers can use Yaskawa Compass graphical user software to design HMI hybrid machines as well as 3D printing, shape cutting, and robotics.

Unlike electron beam and laser powder bed fusion (PBF), Wayland Additive’s Calibur 3 uses NeuBeam technology, which focuses heat on the part instead of the process bed. As a result, the machine is able to process refractory metals and highly reflective alloys.

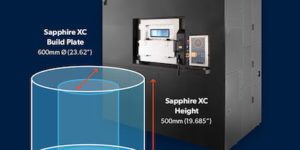

Featuring a build volume of 600 mm x 550 mm, VELO3D’s extra-capacity Sapphire XC uses Flow print-preparation software and Assure quality assurance software to manufacture high-quality parts without using support structures.

Featuring two 300-watt lasers, melt pool and process monitoring, and end-to-end documentation that corroborates quality, Trumpf’s TruPrint 2000 requires fewer add-ons, making the entry-level investment lower for companies that want to get into additive manufacturing.

With a build envelope of 11 by 11 by 14 inches, SLM Solutions’ SLM 280 2.0 is ideal for medium-to-high-volume additive manufacturing. With its build envelope of almost 2 square feet, the 12-laser NXG XII is designed for peak production.

Hexagon’s Simufact Additive powerful and scalable process simulation environment for first-time-right optimization of metal binder jetting (MBJ) predicts and automatically corrects for final distortion and residual stresses of 3D-printed parts.

DP Technology’s Esprit Additive for Powder Bed is compatible with any file supported by SolidWorks. The add-on application streamlines production by eliminating the need to repeatedly define manufacturing information.

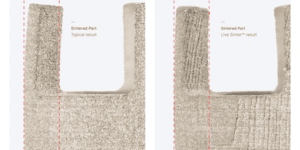

Live Sinter enables inexperienced 3D-printer operators to consistently produce accurate parts using Desktop Metal’s Shop System and Production System machines. The software automatically overcorrects for the shrinkage and distortion inherent in sintering.

Although 3D metal printing is becoming more popular, finishing remains a challenging and arduous task. Understanding how post-processing works and how to measure results will help you optimize this crucial step.

Done right, enterprise resource planning (ERP) identifies and systematically eliminates activities that eat into profits. Here’s how to select a program and partner that will facilitate rather than frustrate the process.

National Association of Manufacturers Chief Economist Chad Moutray explains how pandemic-driven disruption is influencing digitization and data sharing, re- and near-shoring, and hiring.

AMT – The Association For Manufacturing Technology President Doug Woods outlines the six transformative technologies that are helping companies meet swiftly changing market demand without sacrificing quality or employee safety.

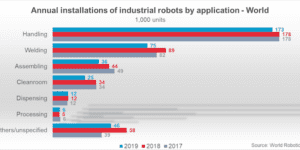

The pandemic prompted manufacturers to fast-track automation plans to safely produce and deliver competitively priced products. Association for Advancing Automation (A3) President Jeff Burnstein explains the potential impact of cobots.

The latest iteration of Mitsubishi Electric Automation’s Melservo-J5 motion control products uses high-speed, high-precision control to maximize machine performance and combines operational technology (OT) and information technology (IT) into a single integrated network.

Based in Ohio, JM Performance Products offers a Made-in-the-USA alternative to imported coupling bolts for Mazak lathes using live tooling. The bolts meet all Mazak specifications and are made from 9310H alloy steel.

The latest iteration of Index Corp.’s 6-axis MS32-6 automatic lathe is even more flexible. Twelve tool slides and patented toolholder locating system speed setups for off-center drilling, threading, contouring, hobbing, and polygonal turning as well as grooving and drilling.

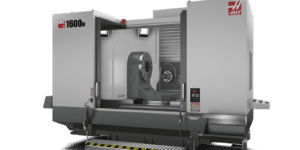

Haas Automation’s UMC-1600-H provides the 50-taper cutting, heavy-duty rotary axes, and large work envelope required to machine large parts for customers in the oil-and-gas, alternative energy, and other heavy industries.

Both a grinding and a turning machine, EMAG’s VLC 350 GT speeds transmission component production by enabling multiple machining processes of chucked parts in a single clamping operation. The flexible machine handles diameters up to 14 inches.

Patent-pending artificial intelligence (AI) capabilities enable DP Technology’s Esprit CAM program to create optimized, edit-free G-code for multiple machine types and setups. The result is highly efficient manufacturing that doesn’t sacrifice safety for speed.

Done right, enterprise resource planning (ERP) identifies and systematically eliminates activities that eat into profits. Here’s how to select a program and partner that will facilitate rather than frustrate the process.

Cutting tools account for 3% to 5% of manufacturing costs, so anything that extends their life will improve profitability. By minimizing waste and freeing employees to perform higher-value work, automated fluid recycling systems pay for themselves in less than a year.

National Association of Manufacturers Chief Economist Chad Moutray explains how pandemic-driven disruption is influencing digitization and data sharing, re- and near-shoring, and hiring.

AMT – The Association For Manufacturing Technology President Doug Woods outlines the six transformative technologies that are helping companies meet swiftly changing market demand without sacrificing quality or employee safety.

Yes, collaborative robots (cobots) are easy to program, but there’s more to optimizing the technology than programming. Here’s how to avoid wasting valuable capital buying a unit that won’t be fully exploited – if used at all.

Campro USA introduces its second-generation 5-axis machining center, the NU550, which delivers big versatility in a small area –– incorporate it in a manufacturing cell with automatic loading, machine transfer robotics or AGV transfers.

The latest iteration of Mitsubishi Electric Automation’s Melservo-J5 motion control products uses high-speed, high-precision control to maximize machine performance and combines operational technology (OT) and information technology (IT) into a single integrated network.

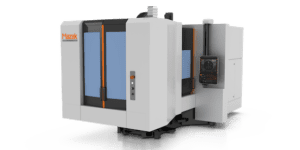

Mazak’s HC-5000 4-axis horizontal machining center (HMC) boosts speed, output, reliability, and precision of numerous metalworking applications in nearly any production environment. Easy-to-program controls automatically calculate intersection coordinates and tool index positioning to optimize cutting.

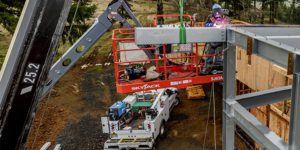

Deemed essential, welding and the related fabricating and metalworking trades weathered the COVID-19 disruption better than other industries, says American Welding Society Executive Director Gary Konarska II. Demand for skilled tradespeople remains high.

Walking back and forth to a vehicle to tweak an engine-driven welder/generator’s control panel takes time. Remote control devices increase productivity by putting the ability to make changes in the palm of the operator’s hand.

Lincoln Electric’s NEXTime preventative maintenance app for Ranger welder/generators monitors critical functions to ensure field workers are working instead of troubleshooting productivity-sapping machine-operation issues.

Huntingdon Fusion Techniques HFT’s HotPurge minimizes the potential for cracking when welding the high-strength steel pipes used in power generation projects. The inflatable purging system is reusable.

Fronius increases seam quality without slowing cycle time with robotic assistance systems by making the wire electrode a sensor as well as filler metal. This eliminates the time and expense of maintaining sensor hardware and doesn’t restrict component accessibility.

Coldwater Machine’s free “Will it Meld” calculator enables manufacturers to easily determine if two dissimilar materials can be joined using the company’s SpinMeld rotary friction welding systems.

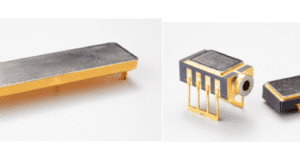

Hermetic Seam Sealing Enables Reliable Welds and Protects Electronic Devices from Harsh Environments

A primer on the two processes – parallel gap resistance seam welding or opposed electrode projection resistance welding – you can use to win customers in the highly demanding aerospace, industrial 5G commercial communications, medical device, and military electronic industries.

Cutting tools account for 3% to 5% of manufacturing costs, so anything that extends their life will improve profitability. By minimizing waste and freeing employees to perform higher-value work, automated fluid recycling systems pay for themselves in less than a year.

Impediments to fully optimized band sawing can be broken into three broad categories: teeth problems, blade problems, and cutting problems. These troubleshooting tips will help operators of all experience levels work as efficiently as possible.

For shops that use shrink fit holders, duplicate assemblies or multispindle machines, Haimer’s VIO linear toolshrink provides fully automated presetting with incorporated shrink fit technology for precise length adjustment on the μm scale that can reduce setup times up to 70%.

The balanced four-insert design of Walter’s D4120 helps deliver process reliability, enhanced surface finishes, and hole tolerances. Balancing cutting forces between the center and peripheral insert ensures hole-diameter precision.

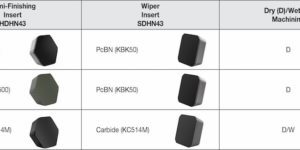

Unpredictable tool life and slow rough-machining speeds hinder heat-resistant super alloy (HRSA) component productivity. New Secomax CW100 silicon carbide whisker-reinforced ceramic insert formats and geometries successfully tackle materials such as Inconel 718 and Hastelloy.

Sandvik Coromant uses a second-generation chemical vapor deposition (CVD) alumina coating to produce two turning grades – GC4415 and GC4425 – that withstand the extreme temperatures of P25 cutting zones during continuous operations.

CNC Software partners with Kyocera SGS Precision Tools to add 10 tool libraries to Mastercam CAD/CAM software. Products include ferrous and non-ferrous cutting tools ranging from end mills, routers, micro tools, and drills to reamers and countersinks.

Kennametal’s KCFM 45 is a flexible, cost-effective, and user-friendly face mill for gray cast iron, CGI applications, semi-finishing and fine-finishing operations on any type of CNC machining center. Produces surface finishes of 0.8µm Ra (32 µin.) or better, and waviness lower than 10µm Wt (400 µin.).

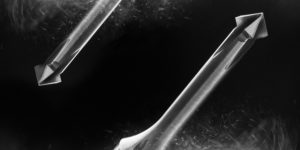

Hoffmann Group’s Garant Master Steel Deep for deep hole drilling improves process reliability at higher cutting speeds. A design that reduces cutting forces and drill guidance that reduces vibration greatly improves hole quality in various machining applications.

Ceratizit’s FreeTurn tools enhance milling machine productivity by combining multiple-propertied inserts with variable approach angles. The spindle rotates the cutting surface 360 degrees to perform roughing, finishing, contour turning, facing, and longitudinal turning with one tool.

Big Kaiser’s Noventa from Sphinx is ideal for 90-degree front and back chamfering, and deburring holes up to 4xD. The milling cutter’s design also delivers a surface that feels like a finished product that’s safe to handle.

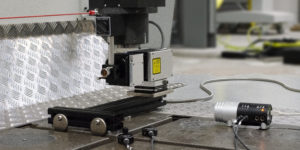

Long-range measurement functionality in Carto 4.2 operating software enables Renishaw’s XM-60 multiaxis calibrator to capture and analyze data from a linear axis regardless of how long it is. The program also facilitates Heidenhain linear compensation.

All Mitutoyo America FormTracer Avant models can be retrofitted with detectors that convert a contour measuring unit or surface roughness tester to a high-precision system that measures both attributes without closing down the software or switching off the controller.

Hitachi High-Tech Analytical Science adds SpArcfire operating software to its mobile optical emission spectrometer (OES) analyzer product line. The intuitive interface makes metals analysis easy, eliminating the need for extensive training or highly experienced operators.

In addition to eliminating paperwork, High QA’s Inspection Manager (IM) Version 5.1 further streamlines collaboration and compliance on the shop floor. Upgrades speed the process of collecting and managing data, from planning through reporting, by five to 10 times.

Exact Metrology offers the RS6 laser scanner, which collects data at full speed regardless of part geometry, for use with the Absolute Arm cobot. The scanner is easily removed from the arm while probing and can be remounted in seconds with no time-wasting recalibration.

For shops that use shrink fit holders, duplicate assemblies or multispindle machines, Haimer’s VIO linear toolshrink provides fully automated presetting with incorporated shrink fit technology for precise length adjustment on the μm scale that can reduce setup times up to 70%.

Equipped with a 16-bit high-dynamic-range (HDR) camera, Mahr’s updated MarSurf CM mobile optical surface metrology tool offers the highest-speed, highest-resolution confocal measurements on the shop floor and in the field.

The latest version of Faro’s flagship software, BuildIT Metrology, is brand-agnostic to streamline manual and automated workflows regardless of what arms, trackers, scanners, imagers, and/or projectors your shop uses.

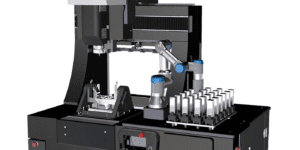

The optical µCMM from Bruker Alicona can measure extremely tight tolerances with high accuracy using a six-axis cobot arm to automatically pick, place, measure and sort (ok/not ok) parts in production.