January 2022

Digital Issue

Be Ready... Planning for the Takeoff. Are you ready for all that 2022 promises? Despite ongoing workforce issues and supply chain hiccups, the manufacturing sector continues to thrive. "We took off last summer and we are about 16 months into what is generally a 36-to-37-month manufacturing expansion," said Timothy R. Fiore, CPSM, C.P.M., chair of the manufacturing business survey committee for the Institute of Supply Management (ISM). The fabricated metal products sector is among the top six U.S. manufacturing industries tracked by ISM each month, comprising 6.1 percent of the manufacturing economy. The sector's PMI has been extremely healthy since September 2020; above 60 percent in October. (Above 50 percent indicates a general expansion.) Find out where Fiore and other manufacturing industry leaders believe opportunities exist in 2022.

Subscribe View Digital IssueThere are a variety of initiatives and programs your shop can utilize to ease the challenge of finding workers.

Accurate and precise cutting fluid recycling equipment contributes significantly to reducing your shop’s annual cutting fluid management operations.

New welding quality analytics packages for the automotive manufacturing industry offer expanded real-time analysis and process improvement for welding operations.

Things are “boomy” for manufacturing and the new year offers opportunities for those shops prepared and positioned to overcome challenges and take advantage of the continuing “takeoff.” The reshoring of production back to the United States is creating opportunities at the regional and local levels. Now is the time to invest, for example, regarding automation and workforce initiatives, and thrive in 2022.

Shipment delays and supply chain bottlenecks can prevent new machinery from being delivered on time, as an example, and imped efficient production and opportunities for growth. One option is to purchase used equipment, which is readily available and less expensive.

Accurate and precise cutting fluid recycling equipment contributes significantly to reducing your shop’s annual cutting fluid management operations.

Advances and customization of press brakes and stamping presses meet your shop’s high-precision requirements, allowing you to better serve your customers.

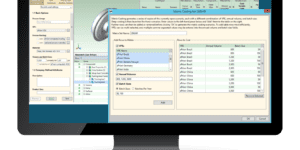

aPriori’s cost-estimating software can benefit

1. engineers designing parts,

2. companies outsourcing the manufacture of parts, and

3. contract manufacturers bidding on jobs. For all three types of users, the software offers quick, accurate, money-saving analysis.

Things are “boomy” for manufacturing and the new year offers opportunities for those shops prepared and positioned to overcome challenges and take advantage of the continuing “takeoff.” The reshoring of production back to the United States is creating opportunities at the regional and local levels. Now is the time to invest, for example, regarding automation and workforce initiatives, and thrive in 2022.

Discover how collaborative robots are solving long standing production challenges.

Shipment delays and supply chain bottlenecks can prevent new machinery from being delivered on time, as an example, and imped efficient production and opportunities for growth. One option is to purchase used equipment, which is readily available and less expensive.

The ability to perform edge contouring on flat sheet cutting lasers makes laser cutting even more flexible as a fabrication tool.

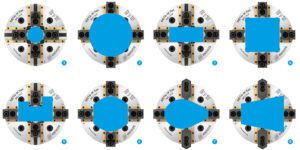

Key components for achieving maximum flexibility and cost-effective productivity.

The manufacturing economy’s booming market expansion is in high gear. Are you positioned to make the most of the opportunities?

aPriori’s cost-estimating software can benefit

1. engineers designing parts,

2. companies outsourcing the manufacture of parts, and

3. contract manufacturers bidding on jobs. For all three types of users, the software offers quick, accurate, money-saving analysis.

Things are “boomy” for manufacturing and the new year offers opportunities for those shops prepared and positioned to overcome challenges and take advantage of the continuing “takeoff.” The reshoring of production back to the United States is creating opportunities at the regional and local levels. Now is the time to invest, for example, regarding automation and workforce initiatives, and thrive in 2022.

Shipment delays and supply chain bottlenecks can prevent new machinery from being delivered on time, as an example, and imped efficient production and opportunities for growth. One option is to purchase used equipment, which is readily available and less expensive.

The manufacturing economy’s booming market expansion is in high gear. Are you positioned to make the most of the opportunities?

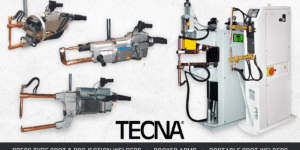

The innovations taking place within the resistance welding market continue to make the process extremely cost efficient.

New welding quality analytics packages for the automotive manufacturing industry offer expanded real-time analysis and process improvement for welding operations.

Understand what causes solidification lines to save your shop unnecessary stress and costs.

Achieve maximum results when cleaning parts, treating hard-to-reach places, and preparing surfaces for additional applications with the latest technologies in cleaners, coolants and lubricants.

Accurate and precise cutting fluid recycling equipment contributes significantly to reducing your shop’s annual cutting fluid management operations.

Accurate and precise cutting fluid recycling equipment contributes significantly to reducing your shop’s annual cutting fluid management operations.

Improvements and advancements in chucks, collets and quick-change tooling speed up your tool changing processes.

Innovative tools improve productivity and process security, specifically when working with titanium and HRSAs.

Keep your shop running smoothly with video inspection systems that provide fast and easy visual inspections of hard-to-reach areas, and which offer your shop flexibility in the measurement process.

In Industry 4.0 data is key, with algorithms adjusting the manufacturing process to ensure repeatable production with zero failure rates. In-process metrology solutions fit within the concept of Industry 4.0 because the process is speedier and covers larger areas than contact devices.