June-July 2015

How the technology and trends in additive manufacturing are changing the production methods of the future.

To run a manufacturing facility around the clock requires planning, the right equipment, efficient processes and the dedication to implement each step for repeatable processes. With these elements in place, a company can work toward its goal of producing perfect parts on time, no matter the customer requirement.

Using either air or water to keep a robotic MIG gun cool is critical because it protects the components from damage due to radiant heat from the arc and resistive heat from the electrical components in the welding circuit. These insights will help you determine if a water-cooled gun is the best fit for your application.

Here is some of the newest equipment and tooling used to bend sheet metal and plate steel.

How the technology and trends in additive manufacturing are changing the production methods of the future.

Sheet bowing is a common problem, but also predictable and therefore able to be addressed.

This look inside the heat treating furnace examines the reasons behind the shift to graphite hot zones and identifies how shops can choose the best hot zone for their heat treating application.

Every shop uses some sort of work instruction method, but the majority of the time it is not ideal. Now there is a new way to easily create and share work instructions, standardize best processes, reduce errors, increase efficiency, and most importantly, satisfy customers.

As engineered imports reach an all time high, compliance to contracted standards carries more potential for hidden liabilities than ever before.

Often neglected in the push to get more parts of higher quality off the cutting table per shift are the very components that generate the high temperature plasma cutting arc. Up to 40 percent of the torch consumable parts that are typically scrapped can often be re-used with excellent cut quality.

Machining is the fastest growing business for this company, which specializes in new part introduction that demands continual investment in the newest and most advanced machine tool technology.

The eye-opening story of how one vertical machining center renovated a small machine shop that makes prototypes and runs small batches for electronics, aerospace, glass and industrial printing applications.

Advanced capabilities. Uninterrupted machining. To move forward in the hyper-competitive world of metal cutting, it’s time to enter into the world of horizontal machining.

Take a look at the advantages of affordable flexibility now being offered in the newest vertical machining centers.

To run a manufacturing facility around the clock requires planning, the right equipment, efficient processes and the dedication to implement each step for repeatable processes. With these elements in place, a company can work toward its goal of producing perfect parts on time, no matter the customer requirement.

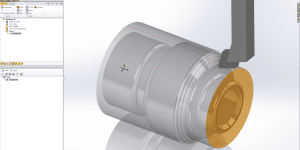

This new CAD/CAM application marries the power and functionality of parametric design with the robust and powerful milling capabilities of standalone CAM software.

Every shop uses some sort of work instruction method, but the majority of the time it is not ideal. Now there is a new way to easily create and share work instructions, standardize best processes, reduce errors, increase efficiency, and most importantly, satisfy customers.

As engineered imports reach an all time high, compliance to contracted standards carries more potential for hidden liabilities than ever before.

Equipment reviews of some of the newest MIG welding systems and accessories for the shop, the field, and for home hobbyists.

Using either air or water to keep a robotic MIG gun cool is critical because it protects the components from damage due to radiant heat from the arc and resistive heat from the electrical components in the welding circuit. These insights will help you determine if a water-cooled gun is the best fit for your application.

This off-the-shelf 10/10 chamber welds titanium with minimal oxygen in the weld area, reaching 10 ppm in 10 minutes to save gas and money.

Silvestrini welding positioners are being used to fabricate massive weldments and hinges in an ingenious flood-defense barrier intended to protect the city.

STX France installed a PEMA Integrated One-sided Laser-Hybrid Welding and Milling Station with an extensive customized conveyor system for welding deck plates together.

Updated training materials on aluminum welding, process introduction, equipment set-up, operation and shutdown, V-groove and butt joint welds in various joint configurations and positions with spray transfer and pulsed spray transfer, and more.

The handy AccuPocket 150/400 TIG weighs only 24 lb and offers two and four-step switchover for welding thin sheets.

The TPS 600i is ideal for mechanized and robot-assisted welding in heavy steel construction that requires a single-wire process and extremely high deposition rate.

The auto-darkening Aristo Tech HD is ideal for greater weld clarity and increased definition of the weld pool, especially when welding for long periods.

Welders can use this tool to choose amperage, cable length, neck, contact tip, wire size, power pin and liner to customize a Clean Air Fume Extraction Gun to their exact needs.

SteelSpace Socket Weld Spacer Rings are composed of Certified 316L stainless steel and provide the pre-measured 1/16 in minimum gap for socket welding contractions required by ANSI 31.1, Section III ASME, and U.S. Naval and Military Codes.

Industrial Passive and Viking 2450 Series Auto-Darkening Welding helmets provide a wide range of functions, from basic protection to advanced technology, for fabricators at all operating levels.

SuperGlaze HD aluminum welding wire is perfect for use in heavy-duty applications where wire feeding can be a challenge and arc performance is critical.

The Aspect 375 TIG welding power source is ideal for critical welding in aerospace, motorsports, shipbuilding, education and fabrication that must meet rigorous testing requirements, including X-ray analysis.

The combination of new engineering with improved and reliable current technology for single source TIG, MIG and/or Stick welding and carbon arc gouging can really increase the operating profitability of jobsites and fabrication shops.

Because maintenance and set-up technicians are often interrupted while working on equipment, this app can be used to secure and cover the control screen so that no one else touches the machine or impedes the repair or set-up.

The Radian laser tracker and four 6-D laser systems further advance their ability to serve the aeronautical and aviation industries.

Take a look at how Fiat Powertrain upgraded the CNC systems of 20 key machine tools used on the crankshaft and cylinder block production lines of its engine manufacturing plant in Campo Largo, Brazil, without interrupting operations.

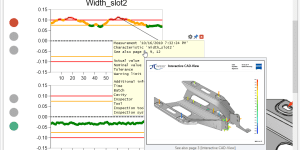

Predicting maintenance requirements is one of the most important benefits of advanced analytics. In the face of a hyper-competitive global economy, the smart use of predictive analytics may be the differentiating factor that sets one fabricator apart from the countless others.

The Aisle-Guard safety barricade from North American Safety Products also prevents passage underneath, even at full expansion.

This machine shop halved its cycle time on producing diesel engine manifolds and rocker arms, saved $300,000 a year in machining costs and sidestepped a $500,000 capital expenditure. All with one tool.

Take a look through this assortment of new cutting tools and discover how they can reduce your machining costs and improve your precision to whole new levels.

Shops in search of process improvements will find the increase in process speeds, higher quality, less tool maintenance and lower operating costs generated by this innovative tooling system anything but boring.

Silvestrini welding positioners are being used to fabricate massive weldments and hinges in an ingenious flood-defense barrier intended to protect the city.

The significantly higher material removal rate of this revolutionary double-sided milling disc reduces costs and eliminates the fine dust associated with grinding to improve worker safety.

Take a look at some of the latest advances in quality assurance software to help your shop remain competitive.