June-July 2016

Probes can shorten cycle time and improve part quality by reducing the opportunity for human error that results in scrap. Here are some tips to help operators use probes to make their machining processes more precise and efficient.

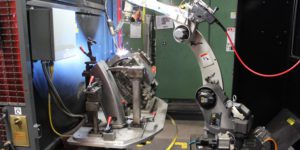

No shop can benefit from welding automation if the operation simply consists of moving a bottleneck from one department into another. To avoid missing out on the overall productivity and efficiency a robotic weld cell can deliver, these four challenges must be addressed before automating the welding operation.

Looking for a creative way to achieve the requested specifications for a potentially lucrative micromachining job without having to invest in a very expensive specialized machine tool? A spindle speeder may be your best – and only – way to secure the deal.

Your shop only has a few months to prepare for the new government regulations that require employers to increase salary levels or pay overtime to millions of employees who are presently ineligible for such premium payments. Here are some insights into the challenges they may present that should be addressed without delay.

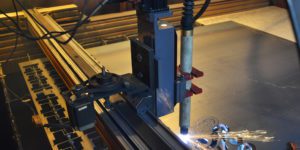

This feature is important in cutting medical devices, electronics and fine mechanics components from thin materials with features that are too small to allow for piercing the drop-out scrap portion of the material.

Take a closer look at how extremely thin strips of anodized aluminum are slit and processed for electronics applications.

The 3D Tube Cutting Line from HGG maximizes automated productivity by eliminating operator interference with a new “press and play” technology.

CO2 laser optics from Laser Research Optics promote sharper cuts with fewer passes and are optimized for 10.6 microns.

The flexible 3 kW LT8.10 fiber laser tube cutting machine from BLM performs extremely precise laser cutting on a variety of materials for tube diameters up to 9.5 in.

The Kyndill Controller Kit from ONExia is a stand-alone, plug-and-play system that includes the automatic height controller, breakaway lifter station, cables, and universal mounting kit for both new and retrofitting applications.

The Eagle eSmart from Power-Tech is ideal for small shops that want to bring fiber laser cutting capabilities in-house to eliminate outsourcing.

The bench-style Red Devil RD7-KHE24 box furnace from Lucifer Furnaces is ideal for batch heat treating small loads of low carbon steel.

The high speed MMB 500 stationary beveling machine from Saar-Hartmetall produces very high quality bevels on small, medium and large aluminum, steel, and stainless steel plate and bar stock workpieces.

Ideal for both steel service centers and job shops, the new heavy-duty HBE-663A high-production, hydraulic horizontal bandsaw from Behringer provides accurate, versatile and economical cutting in all materials, including structural steels and high-tensile strength solids.

The PMM 200MD Movable Frame Press from Dake is ideal for assembly work and straightening applications.

Part program specialists that typically create five drawings a day can now do as many as 30 or 40.

Here is a sneak peek at some of the fabricating, laser and waterjet-based technologies that will be exhibited on the show floor at McCormick Place in Chicago from September 12-17.

TECHNI Waterjet and Micro Waterjet have teamed up to combine high precision cutting capabilities with the latest in high pressure pump technology.

A functionally integrated, bionically optimized vehicle structure offers new potential for lightweight construction and greater manufacturing flexibility of automobiles.

The VIS-P portable laser marker from Automator America is ideal for marking metals, alloys, and anodized, painted surfaces of large, oversized components.

Using a precision 4-axis back gauge with a fast acting ram and higher bending force, the Dyna-Press 40/15 Plus from LVD Strippit produces extremely consistent, repeatable and accurate parts at a lower cost.

This interactive iBook from AXYZ examines various CNC router applications with videos, photos and detailed written information that illustrates specific features and benefits.

This latest innovative roll forming system from Samco produces parts Just-in-Time at variable speeds up to 60 fpm, depending on the punching pattern and part lengths.

From start to finish, the honing mastery of Nick Ferri is behind 57 national event NHRA Pro Stock victories and five championships, including back-to-back titles for 2015 champion Erica Enders-Stevens.

The compact, lightweight MABasic 450 drill from CS Unitec is an ideal hole-cutting solution for steel fabricators, contractors and maintenance operations.

Mastercam X9 Design offers a suite of shop-tested design tools that get parts on and off the machine as quickly as possible.

A a new compact wheel changer from United Grinding provides more set up and part processing flexibility and boosts overall output through continuous uninterrupted machine operation on Walter Helitronic Mini Power grinding machines and Helitronic Diamond Evolution two-in-one eroding and grinding systems.

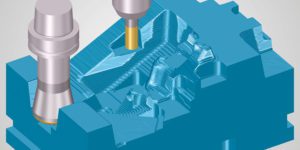

Version 4.0 Release 2 CAD/CAM software from Tebis is especially well-suited for rough machining of deep cavities and hard material.

The lightweight, powerful, high-speed 6-axis Racer3 articulated robot from Comau features a payload of 3 kg and reach of 630 mm that can be mounted on benches, walls, ceilings or inclined supports.

New web-based machine monitoring dashboards and new monitoring reports from eNETDNC help shops increase their machine uptime.

Alphacam 2016 R2 from Vero improves machining performance with enhanced feature extraction and automated management of part geometry.

RV-35F, RV-50F, and RV-70F robots from Mitsubishi handle higher payloads requiring longer reaches in CNC machine tending, large material handling jobs and assembly work.

Here is a sneak peek at some of the metal cutting equipment that will be exhibited on the show floor at McCormick Place in Chicago from September 12-17.

Here is a sneak peek of some of the digitally-enabled tools that will be exhibited on the show floor to help define Smart Manufacturing, the Industrial Internet of Things, Industry 4.0 and other advancements in the digital enterprise.

Here is a sneak peek of some of the grinding technology that will be exhibited on the show floor at McCormick Place in Chicago from September 12-17.

Probes can shorten cycle time and improve part quality by reducing the opportunity for human error that results in scrap. Here are some tips to help operators use probes to make their machining processes more precise and efficient.

The CTX gamma 2000 TC second generation turn-mill machining center from DMG MORI is ideal for profitable machining of extremely complex parts.

RP6 from Lincoln Electric provides up to six months of indoor corrosion protection by preventing rust on ferrous metals while not adversely impacting the welding process.

The powerful, flexible, pre-engineered ArcWorld 2000 workcell from Yaskawa Motoman is perfect for low to medium volume shops with a medium to high mix of parts.

Designed exclusively for TOUGH GUN TT3 and TT3E Reamer robotic nozzle cleaning stations, the simplified TOUGH GUN Reamer Stand from Tregaskiss installs quickly for swapping between weld cell stations.

Weld Trailing Shields from Huntingdon Fusion Techniques ensure that the weld remains under an argon gas shield until the metal has cooled below its oxidation temperature.

Victor G150, GT350 and GRF400 regulators from ESAB use a color combination on the gauge face that provides clarity for reading the needle position, with scale and red tick marks to indicate actual service pressure.

The Surfox Wand from Walter Surface Technologies features a quick-change system for accessories to clean larger and hard-to-reach areas at an optimal rate.

Tube and Pipe Weld Purging Systems from HFT pay for themselves in the first weld, saving vast amounts of purging time and inert gas costs.

The Hobart Filler Metal Selector and Calculator determines the filler metal volume required and more for specific weld joints.

No shop can benefit from welding automation if the operation simply consists of moving a bottleneck from one department into another. To avoid missing out on the overall productivity and efficiency a robotic weld cell can deliver, these four challenges must be addressed before automating the welding operation.

Many sheet metal fabrication shops still hesitate to invest in laser welding. They are missing out on the numerous competitive advantages and opportunities that it offers over conventional welding processes. Here are some insights that they need to know.

Costing about 50 percent less than comparable cobalt materials, 5551 flux-cored wire from Weld Mold retains superior hardness in temperatures up to 1,200 deg F.

Ideal for heavy equipment welding and for equipment used in severe service conditions, the new FabCO 85HXP gas-shielded flux-cored wire from Hobart Brothers can operate at higher wire feed speeds to increase deposition rates and travel speeds on thicker materials for higher productivity.

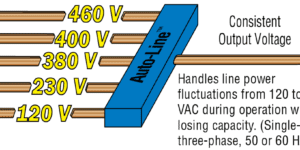

Dirty power can impact weld quality in many ways. Here is one way to help avoid the problems caused by dirty power and improve productivity, efficiency and weld quality.

Aluminum is popular in many fabrication applications, but welding the material presents challenges of cracking, porosity and burn-through on thinner sections. Here are some critical insights on how to combat these potential problems.

The MAWA-300A Pulsed Micro TIG Welder from Amada Miyachi has a unique touch start feature to control and identify weld location when welding small coils and terminals, bus bars, and covered wires used in the automotive, medical, battery and electronics industries.

This robotic grit blaster uses an RXS-400 Rotary-Index Twin Spindle machine from Guyson for its operating platform.

Made from a tough PVC vinyl curtain, the LiteSpeed Clean high speed door from Rite Hite has a tapered design that uses non-exposed fasteners, making it more resistant to collecting dust than flat surfaces and easier to clean.

The high performance DustHog PNP cartridge dust collector from ClarCor reduces installation and service time while collecting dust and fumes to save energy and operating costs.

Jongen installed advanced fine filtration systems from Vomat that provide temperature-controlled clean oil for insert production and tool cutting.

Here is a sneak peek at some the goods needed to run your plant, from the parts to service and monitor your machines to the components necessary for safe and environmentally responsible operations.

You know the price of your ventilation or dust collection equipment, but do you really understand all of the ongoing expenses involved in maintaining indoor air quality for your shop? Time for a sanity check.

The Dustmaster 6,000 cfm Electric Dust Collector from Marco uses a reverse incline blade fan matched with a 15 hp Baldor electric motor to remove airborne dust and debris from an enclosed work site so workers have better visibility to the work surface and can increase their production rates.

This international accolade recognizes the outstanding product design quality of the scanner.

This machine safety brochure from AVENTICS explains directives and standards for safety-related pneumatics through product applications and circuit diagrams.

Monaghan Tooling offers Swiss ID Burnishing Tools by Elliott Tool Technologies that are ideal for accurate sizing, low micro-finishing and surface hardening of ID holes down to 4 mm.

Osborn introduces a new catalog of surface treatment solutions and high-quality finishing tools.

POLIFAN CURVE flap discs from PFERD remove weld seams and slag, leaving a smooth finish for easy identification of cracks, inclusions, and porosity in the fillet during weld inspections.

M4256, M4257 and M4258 helical cutters from Walter are ideal for machining steel, cast iron, stainless steels and difficult-to-cut materials.

Using the Insta-Quote system from Allied Machine, shops can quickly design, draw and obtain a quote; instantly print it out with a PDF drawing; then confirm, process and deliver the order through a local distributor.

Niagara solid-carbide thread mills provide cost effective, highly accurate production of Unified, National Pipe Tapered and Metric thread forms.

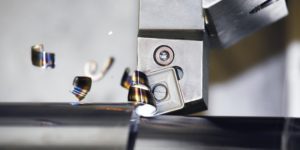

PCD Insert Increases Productivity and Cost Efficiency in High-Speed Machining of Non-Ferrous Materials

With VideoWDN10 polycrystalline diamond inserts from Walter USA have superior wear resistance that delivers outstanding hardness for exceptional cutting edge sharpness to achieve excellent surface finishes.

The Ultra QCT system from Mate Precision Tooling features a simple, intuitive tool-less punch retention mechanism for easier, faster setups by simply flipping the latch to remove and snap the new insert into place.

The GC1130 insert from Sandvik Coromant uses Zertivo technology to provide a clean and intact edge that delivers high metal removal rates and performance levels in both wet and dry machining operations.

Polycrystalline Diamond T-A Drill inserts from Allied Machine can withstand strong and highly abrasive materials like CFRP-titanium stacks, aluminum, titanium, copper, magnesium, fiberglass, and chipboard used in the aerospace and automotive applications.

When using swing ears from Wilson Tool to bend boxes with four sides and return flanges, forcing the punch out of the box when making the final bend is no longer necessary because the ears simply swing out of the way.

The Adjustable Slide 45 deg Mirror from R&R Fixtures allows inspection and viewing of the part from all sides.

Ideal for high speed machining, Dillon Jaw Nuts and Keys provide superior wear resistance, impact resistance, higher tensile strength, and extended jaw nut life.

The positive cutting geometry of new Sphinx micro engraving cutters from BIG KAISER are appropriate for work in most materials, from alloyed and unalloyed steels to thermosetting plastics and even titanium.

The BLAXX M3016 from Walter tackles ISO material groups P, M and K, and difficult applications such as machining frames made from cast iron for large molds, or housings for wind energy rotor hubs.

Here is a sneak peek at some of the state-of-the-art tooling and workholding systems that will be exhibited on the show floor at McCormick Place in Chicago from September 12-17.

Flat-I cylinders from Bimba are ideal for medical, food and beverage or health and beauty applications that require frequent, corrosive wash downs to prevent the propagation of bacteria.

Monaghan Tooling offers “Speed-Drill R4” geometry in solid carbide round tools from MK Tools that effectively drills all popular materials used in automotive engine and chassis components.

To deliver Inconel parts on time with zero scrap, this aerospace supplier uses 4-flute and 6-flute end mills constructed of SiAlON KYS40 grade ceramic for roughing nickel-based high-temperature alloys.

Looking for a creative way to achieve the requested specifications for a potentially lucrative micromachining job without having to invest in a very expensive specialized machine tool? A spindle speeder may be your best – and only – way to secure the deal.

This new linear finishing set from PFERD is ideal for rough stock removal, surface conditioning and consistent, high-quality cosmetic finishing on all metals.

The slim design of TRIBOS-SVL toolholder extensions by SCHUNK allows precise and smooth machining of areas on parts that are difficult to access.

The unique positioning of the tilted inserts in the CoroMill 745 from Sandvik Coromat is ideal for roughing to semi-finishing steel and cast iron materials in all types of milling machines.

Built with a 0.045 in cutting edge, the general purpose VERSA-CUT abrasive cut-off wheel from Rex-Cut can be used in almost any cutting application to provide the cutting speed of a thin wheel while maintaining the longevity of thicker options.

Synergy 1000 Cloud from Zontec includes enhancements that further the accessibility to real-time data collection, charting, monitoring, analysis, communication and reporting.

The Elbo Controlli Tool Presetter App from Koma Precision enables users to easily measure tool radius and length and directly send the offsets to the Okuma OSP-P control to update the local tool offset table.

The O-Select optical measuring system from Zeiss is ideal for checking the dimensional accuracy of distances, radii or angles in punched, turned and formed parts, injection molded parts, and laser cut parts.

The Spectroline TRITAN 365 from Spectronics uses three ultra-hi-flux UV-A LEDs for NDT inspection plus an intense white light LED to illuminate dark work areas.

The ThreadChecker sensor from Kaman Precision uses proven eddy current technology to check threads, regardless of part cleanliness.

The BLAZE 600M from Hexagon is ideal for measuring parts around stamping presses, CNC machining and robotics.

The Multimar 25 EWR Digital Universal Caliper from Mahr Federal is ideal for measuring outside and inside dimensions, narrow collars, external and internal tapers, dovetails, grooves, distances between hole centers, for centering shoulders, scribing parts and more.

The new HP-S-X1 scanning probe series from Hexagon has been redesigned for greater durability and improved setup flexibility without the need to change modules.

The VR-3000 Series from Keyence provides an instant, non-contact 3D scan of a wide area that has been difficult to achieve with conventional methods. It can easily measure rough surfaces, flatness, warpness, and planarity.

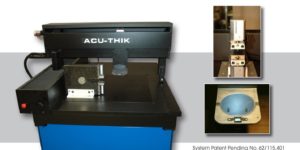

ACU-THIK from Acu-Gage is an automated thickness measurement tool incorporating dual contact probes for high accuracy inspection of semiconductor wafer diameters of 100 mm to 400 mm and beyond.

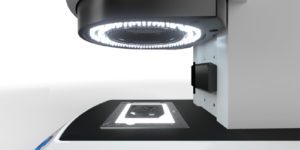

The XG-X vision system from Keyence combines high-resolution 3D height images with ultra-high speed processing for inspection that cannot be done with conventional laser profiling or traditional 2D imaging.

Here is a sneak peek at some of the metrology equipment and systems that will be exhibited on the show floor at McCormick Place in Chicago from September 12-17.

With no user intervention, Wilson VH1102 and VH1202 universal micro-hardness testers from Buehler provide flexible, cost-efficient and reliable Knoop and Vickers testing with high precision and repeatability within a minimum of time.