June/July 2020

Digital Issue

Manufacturing as a Secondary Operation: Entrepreneurs make software as well as parts. As supply chains reconfigured to domestically produce personal protective equipment (PPE), the global pandemic underscored the need to swiftly and accurately respond to potential orders. Fabricating and metalworking companies that harnessed equipment expertise to digital tools that streamline manufacturability analyses and integrate with back-office resources won the day. We look at why and how one CNC machining company, Plethora Corp., treats manufacturing almost as a secondary operation.

Subscribe View Digital IssueNot even a pandemic can interfere with metalworking’s inexorable technological progress. Blowing way past automation, entrepreneurs are harnessing digital know-how to solve analog problems — wherever they find them.

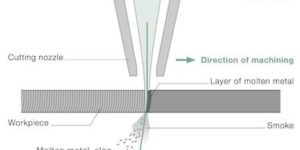

Trumpf’s Active Speed Control uses artificial intelligence to completely eliminate the need for an operator to monitor cutting and, if necessary, tweak parameters. The technology automatically adjusts feed rate to ensure part quality when cutting plate with chemistry, thickness, or surface condition variations.

As many fabricating and metalworking companies seek to revitalize production in these trying times, a new sense of urgency is prompting creative approaches to automation. While each shop will forge a unique path to its own new reality, they’ll share common challenges and solutions.

Designed as an alternative to hydraulic cylinders, Tolomatic’s extreme-force electric actuators provide long life and reliable performance in demanding conditions. The RSX128 represents a 60% increase in bidirectional maximum force.

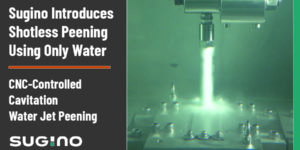

Sugino Machine adds waterjet peening with up to 5-axis CNC control to its lineup of equipment that uses water to atomize, deburr, and clean. Peen inside holes, tubes, and cavities without masking or the waste and mess of standard shot peening.

The latest iteration of Mitsubishi Electric Automation’s Melservo-J5 motion control products uses high-speed, high-precision control to maximize machine performance and combines operational technology (OT) and information technology (IT) into a single integrated network.

IHI Hauzer’s Flexicoat 1250 batch-coating machine for physical vapor deposition (PVD) lowers cost per coating by featuring a 33% loading increase compared to its predecessor. Fixtures are fully compatible with the older machine’s fixturing.

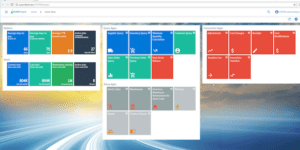

Global Shop Solutions’ Cloud ERP combines maintenance-free software and speed with quick and simple, automatic cloud-based data backups. Files and data are never lost; updates and maintenance are done in-house so users always work with the most up-to-date version.

An upgrade to the CSD-300 twin-spindle lathe, the front-facing CSD-300II from Fuji Machine America is more robust and loaded with new-or-improved features for faster and easier operation than its predecessor.

Cosen Saws, North America plans to showcase at least four fully automatic band saws suitable for high-volume production as well as a jack-of-all-trades utility toolroom band saw at IMTS.

For almost a decade, machine tool consumption in the U.S. has increased and China’s has decreased. As global supply chain emergencies accelerate a manufacturing migration to the U.S., metal fabrication and machining companies that use manufacturing as a service (MaaS) platforms stand to benefit.

Trumpf’s Active Speed Control uses artificial intelligence to completely eliminate the need for an operator to monitor cutting and, if necessary, tweak parameters. The technology automatically adjusts feed rate to ensure part quality when cutting plate with chemistry, thickness, or surface condition variations.

As many fabricating and metalworking companies seek to revitalize production in these trying times, a new sense of urgency is prompting creative approaches to automation. While each shop will forge a unique path to its own new reality, they’ll share common challenges and solutions.

The world’s top engine builders and auto enthusiasts rely on Borla Performance Industries exhaust systems, but parts were taking too long to program and produce. Switching from CNC machining to automated plasma cutting is drastically reducing cycle times.

A sawing specialist asks and answers four basic questions about feed rate and feed pressure, blade life, determining cutting feed and cutting speed, and optimizing tooth selection.

3D printing powders maximize part quality, but many are the suppliers from which to choose. In this Q&A, the president of GEMCO notes the industry is turning to contract powder processors for sophisticated heat treatments that improve quality.

At least one of this Georgia sheet metal fabricator’s 130 employees has tested positive for the coronavirus. President Bruce Hagenau shares how METCAM is keeping the rest of the team – and their families – safe.

Dewalt is serious about staying the course so their people can serve myriad frontline folks during the pandemic. A lengthy list of protective protocols has kept their operations going to meet the daily demands of their business partners.

Scotchman Industries, Inc. split its workforce and rotates the teams for onsite and remote duty to decrease the odds of everyone catching COVID-19. Management also took the bold move to pay all employees during their offsite shifts, whether their jobs can be done remotely or not.

The nation’s largest manufacturer of metalworking lubricant proportional/mixers and spray application lubricating systems continues pumping out product.

LVD Strippit has kept its New York plant and all four of its North American support facilities open during the pandemic to continue supplying parts and aftermarket service to essential manufacturing businesses. And when remote service isn’t enough, their techs hit the road to keep customers’ equipment running smoothly.

Hypertherm initiated CDC and WHO hygienic and social distancing protocols in mid-March. The company also has close to half of its associates working at home, and those coming in to work are wellness-checked before entering the facility.

Star SU’s single-flute solid-carbide gundrills are engineered and manufactured to meet part print requirements when working with the complete range of titanium and stainless steel materials.

Rollomatic’s 5-axis LaserSmart 510 laser-cutting and ablation machine produces a superfine and cost-effective diamond-coated cutting edge with a surface finish that isn’t possible with EDM, electro-discharge (EDG) or grinding.

The latest iteration of Mitsubishi Electric Automation’s Melservo-J5 motion control products uses high-speed, high-precision control to maximize machine performance and combines operational technology (OT) and information technology (IT) into a single integrated network.

Custom DeHoff 3060 boring machine features Beckhoff CNC controls and 40-horsepower spindle motor with 4-speed gearbox to meet rigorous material-removal requirements. Workpiece loading and fixturing can also be customized.

Global Shop Solutions’ Cloud ERP combines maintenance-free software and speed with quick and simple, automatic cloud-based data backups. Files and data are never lost; updates and maintenance are done in-house so users always work with the most up-to-date version.

An upgrade to the CSD-300 twin-spindle lathe, the front-facing CSD-300II from Fuji Machine America is more robust and loaded with new-or-improved features for faster and easier operation than its predecessor.

DP Technology has tweaked its flagship Esprit CAM software platform to serve a growing fabrication market: 3-D metal printing using powder bed fusion (PBF) and directed energy deposition (DED).

Cosen Saws, North America plans to showcase at least four fully automatic band saws suitable for high-volume production as well as a jack-of-all-trades utility toolroom band saw at IMTS.

Dynabrade’s Dynafile grinds, deburrs, blends, and finishes normally inaccessible areas on metal, plastic, fiberglass, and other composites, and does light corner weld removal and blending of welds. Belt-tracking system ensures trouble-free operation.

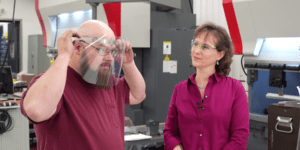

San Francisco-based Plethora Corp. shaves as much time as possible from the iterative design process. After developing software that enables customers to design for the shop’s capabilities in real time, this 2017 start-up delivers prototypes and production runs within three days.

At least one of this Georgia sheet metal fabricator’s 130 employees has tested positive for the coronavirus. President Bruce Hagenau shares how METCAM is keeping the rest of the team – and their families – safe.

Dynabrade continues manufacturing its American-made power tools from its facility outside of Buffalo, N.Y. Products are in stock and ready for immediate shipment.

Mazak’s HC-5000 4-axis horizontal machining center (HMC) boosts speed, output, reliability, and precision of numerous metalworking applications in nearly any production environment. Easy-to-program controls automatically calculate intersection coordinates and tool index positioning to optimize cutting.

KME CNC 5-axis tombstones and trunnions and 4- or 5-axis rotary tables turn 3- axis and 4-axis machining centers into 5-axis production machines. The wireless KME TS630 tombstone transforms horizontal machining centers (HMC) into 5-axis machines that operate lights-out for eight hours at a time.

High utilization rates can hinder machine tool performance. High-speed spindle manufacturer IBAG North America provides uptime by offering repair services including condition evaluation, internal-parts analysis, and rebuilding from its North Haven, Conn., facility.

German Machine Tools of America (GMTA) is selling the full line of Samag MFZ Series multispindle machines for high-volume cubic workpieces. Applications include knuckles, engine blocks, gear boxes, valves, and connecting rods for the automotive powertrain, truck, and off-highway markets.

Todd White started to do a couple jobs a month with one Tormach machine in his garage. After qualifying to become a Xometry manufacturing partner, he’s become a full-fledged shop with multiple machines and work for a wide variety of customers.

The industry’s first IP67-rated collaborative robot, Yaskawa Motoman’s HC20XP is particularly well-suited for use in damp and splash-prone environments such as food processing. Two speeds optimize cycle time based on risk assessment and process requirements.

Yaskawa America’s ArcWorld 6000 pre-engineered workcells featuring Motoman AR-series arc welding robots come with virtually everything you need to get up and running quickly and safely. Available in one-, two-, or three-robot configurations.

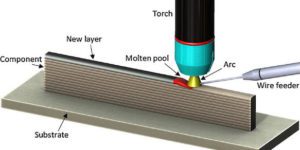

Unlike powder-based additive manufacturing, this second method of additive manufacturing uses a standard high-deposition process and readily available materials. Wire arc additive manufacturing (WAAM) is particularly cost-effective for prototypes and small-batch production runs.

Pemamek’s PEMA nozzle welding solution eliminates heavy welding’s drudgery and inaccuracy. Built-in lasers scan the geometry of each layer, which the robot’s control software uses to automatically generate the ideal path for the next pass.

Unlike water-based materials that leak or slip from position, HFT’s weld purge film doesn’t contain water but is water-soluble. After being used to produce quality welds on tubes and pipes, the film dissolves and washes away.

Intelligent occupational safety: That’s what Fronius offers in the Vizor Connect. Communicating with the power source via wireless Bluetooth communications technology, the helmet’s visor darkens as soon as the welder turns on the torch.

Weld with any stick electrode type wherever the work takes you with ESAB’s lightweight and reliable Miniarc Rogue ES 180i TIG inverter. A stable arc down to 10 amps provides the control welders need on thin metal or delicate components.

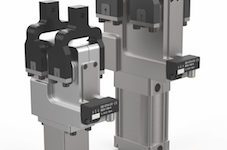

Individually adjustable arm opening angles and tolerance compensation enable Destaco’s Model 84A40-1/84A50-1 power clamps to minimize changeover times by giving welders more flexibility. Don’t worry about harsh operating environments because contaminants can’t penetrate the enclosed design.

Even seasoned welders don’t always remember – if they ever learned – all the basics regarding techniques and materials. Optimize fabricating operations and help plug your future skilled-labor gap by instilling good habits from the start.

With a customer base predominantly comprised of essential businesses, Bluco Corp. remains open and committed to earning their trust. Donning all the necessary PPE and abiding by all of CDC’s and Illinois’ mandates, the modular fixturing manufacturer has a big advantage: They’ve got what they need in-house to create customer solutions.

Developed specifically for manufacturers, the SYSPRO enterprise resource planning (ERP) platform automates and integrates business processes to improve production, inventory control, and reporting. Recent enhancements enhance security, compliance, traceability, and tax reporting.

Do any of your processes rely on an outdated operating system? This enhanced operational technology (OT) endpoint protection prevents unplanned shutdowns via stronger asset detection and vulnerability response capabilities.

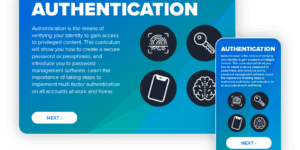

Mobile-friendly eLearning Brothers Cybersecurity Awareness training modules keep students engaged and moving quickly through the content with short, bite-sized activities structured around the goals of ‘learn, rehearse, and perform.’

A New York sheet metal prototype specialist is sharing PDF and DWG files it developed to make face shields comprising a Mylar shield with an adjustable stainless steel headband. Unlike much personal protective equipment (PPE), they can be used more than once.

Suhner Industrial Products’ extensive POLYDrill family provides drilling capacities from 0.06 inch to 1 inch (1.5 mm to 25 mm) and speeds of up to 20,000 rpm.

An AC inverter drive on the BEX 15 high-speed block spindle from Suhner Industrial Products increases spindle speed to 23,000 rpm at 87 Hz. Two slide-assembly mounting options enable multiple operations.

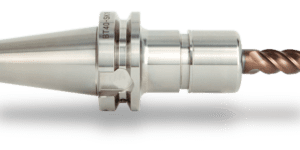

Available in a wide variety of toolholder lengths and diameters for optimal rigidity and clearance, Samchully Workholding’s SK series provide 1 micron runout accuracy as well as three times better runout repeatability and double the gripping force of a comparable ER collet chuck.

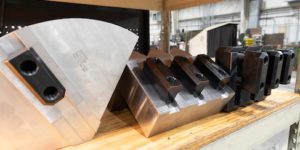

Ideal for workholding applications that require durability and high strength, such as high-speed machining, Dillon’s Fast-Trac jaw nuts provide more productivity per square foot of manufacturing space. They convert standard chucks 6 inches to 24 inches in diameter into quick-change chucks.

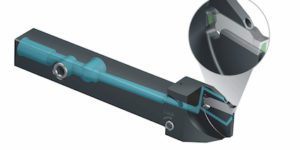

Ceratizit offers the first standard FreeTurn indexable inserts for its high dynamic turning (HDT) system. The system greatly enhances the productivity of a single milling machine by combining multiple-propertied inserts with variable approach angles.

Brush Research Manufacturing’s Flex-Hone finishing tools are available with cubic boron nitride (CBN) abrasive, which combines the highest hardness with excellent toughness for success with difficult-to-finish surfaces.

BIG KAISER’s Chip Blower helps machines reach maximum productivity levels by safely and efficiently removing coolants and debris. The blower complements the ChipFan the company introduced several years ago.

Tramming in a workpiece or fixture to a machine, measuring lengths and depths, checking flatness, or aligning workpieces and vise? Haimer USA’s 3-D sensors make locating the edge in XYZ as easy as 1-2-3.

With loading capacity up to 20,000 pounds, Bluco’s high-tolerance 3-D welding tables are hardened to protect against spatter build-up, provide a corrosion-resistant surface, and come with a lifetime warranty.

Consisting of a base plate and components, Bluco’s modular fixturing systems cut setup time in half compared to manually tooling up. The company can customize extra-large fixturing kits featuring base plates up to 20 feet.

An expanding array of design and connectivity options is making this tooling method faster and easier. This cost/benefit analysis shows why shrink fit’s benefits extend beyond mold-making and 5-axis machining applications.

As many fabricating and metalworking companies seek to revitalize production in these trying times, a new sense of urgency is prompting creative approaches to automation. While each shop will forge a unique path to its own new reality, they’ll share common challenges and solutions.

Change inserts approximately 70% faster with Walter’s G4014-P groove turning holder and double-edged DX18 indexable inserts. ‘SmartLock’ feature enables users to access the clamping screw from either side.

The VLaser 270 completes Vollmer of America’s range of grinding and erosion machines for tool manufacturing. Fixed-beam laser machines polycrystalline diamond (PCD) into highly precise cutting tools for chip guide notches and chamfers.

Can’t decide which material, grit pattern, mounting option, and/or other attribute is appropriate for a particular application? Superior Abrasives provides recommendations for more efficiently processing the workpiece.

Seco Tools’ quick-change system enables fast, easy, and repeatable insert indexing and tool changes outside of tight machine work spaces. Both cutting heads and inserts can be removed as a single assembly for quick indexing and reinstallation.

Emuge Corp.’s A-H taps penetrate materials up to 48 RC hardness. Available with or without coolant thru-holes and with TiCN coating or NT nitride surface treatment for longer tool life.

Designed for high-volume production via CNC lathes and multispindle machines as well as automatic lathes, Walter’s G4014-P grooving toolholder and MX22-2L/R indexable inserts with two new geometries provide stability, precision, and indexing accuracy.

The newest version of Monaghan Tooling’s Reamtec easyZERO nuts feature six adjustment screws that allow for more accurate machining. Users can correct runout errors and misalignment for all round tools with virtually no scrap.

Kurt Manufacturing’s pre-engineered Pyramid bundles enable clamping of three components in one fixture in a single setup. They’re standard for 12 5-axis vise models and handle parts from 2 inches to 7 inches.

Designed for forming threads with improved surface quality, Emuge Corp.’s Innoform–Steel-M line of HSSE-PM taps increase static and dynamic thread strength in medium-strength steels up to 44 HRC.

Stability affects everything from profitability to employee safety. Big Kaiser’s zero-point Unilock Stabilizer 50 provides consistency by quickly and easily adjusting to new parts whether you’re machining, welding, or assembling.

Some operators learn as they go or get advice from coworkers who may (or may not) have received appropriate training. Unfortunately, learning about abrasives through trial and error can cause unnecessary accidents and injuries while negatively impacting productivity and costs.

With a customer base predominantly comprised of essential businesses, Bluco Corp. remains open and committed to earning their trust. Donning all the necessary PPE and abiding by all of CDC’s and Illinois’ mandates, the modular fixturing manufacturer has a big advantage: They’ve got what they need in-house to create customer solutions.

Tramming in a workpiece or fixture to a machine, measuring lengths and depths, checking flatness, or aligning workpieces and vise? Haimer USA’s 3-D sensors make locating the edge in XYZ as easy as 1-2-3.

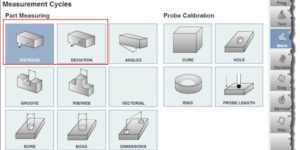

A software wizard for NUM’s Flexium+ CNC systems enables total automation of probe measurement on the shop floor. Operators don’t need to know G-code because the software provides visual prompts for 29 calibration, presetting, and/or measurement routines.

Mitutoyo America’s M2 2D processor package is available with a PH-3515 profile projector with 14-inch touchscreen tablet. The horizontal projector is equipped with accurate linear glass scales and performs profile and fiberoptic surface illumination.

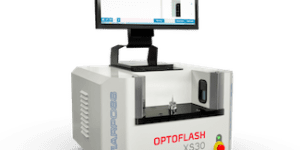

Marposs’ OptoFlash Xs30 meets the measuring requirements of extra small components for the precision mechanical devices and medical implants industries. The 2D optical inspection system handles 100 static measurements in 2 seconds.

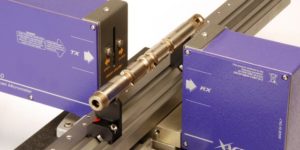

Marposs’ Meclab.X’s Aeroel technology eliminates measurement drift caused by changes in room temperature. The micrometer system doesn’t require a PC and is easy for inexperienced operators to learn, so it’s ideal for common measurement applications throughout the shop.

Mahr’s Micromar 40EWR digital micrometers address a conundrum manufacturers face every day: how to measure unique objects and surfaces in widely diverse scenarios. Wireless data transmission is available for each of the five models in the series.

Mahr depth gages transmit measurement data wirelessly, simplifying recording and documentation and facilitating networked production. Pocket-sized 30 EWRi travels easily all over the plant floor; 30 EWR-U and 30 EWRi-U universal gages open the door to numerous applications.

Designed for Hexagon’s 7-axis Absolute Arm, the RS-Squared area scanner adds 3D laser scanning to touch probing to measure parts faster than conventional scanners. No reference markers are required, and that’s the silver bullet that keeps overall scan time to a minimum.

The latest software for Heidenhain’s Acu-Rite family of digital readouts(DROs) features at least three enhancements designed to increase productivity and efficiency. One adds Axes Q on the axes’ names list for customers who use their DROs on optical comparators.

Available from Exact Metrology, the Leica RTC360 laser scanner generates a full model of large-scale objects with down-to-the-millimeter accuracy. Built-in Leica Cyclone Field 360 app automatically registers scans in real time, and software integrates the 3D model into the user’s workflow.

Brucker Alicona’s µCMM enables inexperienced operators to confidently and accurately measure component dimension, position, shape, and roughness. MetMaX operating software turns the coordinate measuring machine (CMM) into a planning and reporting system as well.

Combining dimensional metrology and surface roughness measurement, the InfiniteFocus G5 from Bruker Alicona provides high repeatability and vertical resolution of up to 10 nanometers. An interface equips the system for fully automatic measurement during production.

Alio Industries’ HH-30D Hybrid Hexapod offers unprecedented XY travel ranges with nanometer-level precision. Unlimited number of tool center point (TCP) locations can be programmed via forward and inverse controller kinematics.

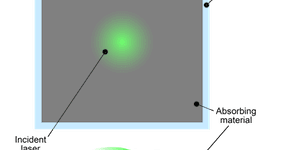

Output power can be measured with one of three types of sensors: photodiode, thermopile, and thin-film thermoelectric. Here’s how to decide which one will most cost-effectively meet your process application needs.