March 2019

Digital Issue

Is the robot revolution really such a bad thing? As automation and robotics sweep through manufacturing, Smart Factories driven by digital information are slowly emerging as an ultra-lean answer to the skilled labor shortage and other competitive issues.

Subscribe View Digital IssueThough scrap metal is often regarded as a waste or by-product from fabrication operations, it is actually a viable revenue source – in fact, it is the second largest revenue source next to the finished product. This is why shops should have a formal management system in place to maximize the revenue they generate from scrap.

The problem may be as simple as a loose contact tip or something more complex, like incorrect TCP. Understanding the steps for proper troubleshooting helps narrow down potential causes, prevents replacement of components that don’t need replacing, and quickly gets you back to producing quality parts.

As machine tool manufacturers work on enabling technology to make the Smart Factory possible, the field of machine service and support has started to drastically minimize the window of lost productive time that shops must deal with.

With automated tool changing, bend simulation software with 3D part views, intelligent angle measuring systems and other features, here are some new press brakes that can efficiently bend small batches of high-mix parts, including difficult profiles, with high precision at fast speeds.

The No. 828 cabinet oven from Grieve is ideal for uniformly finishing batch loads of metal parts at 500 deg F.

Model 42-B18 convection ovens from Lucifer Furnaces heat uniformly to 1,200 deg F with recirculating air flow from a rear-mounted heavy duty fan that directs air along side wall heating elements then through the working zone.

Is the robot revolution really such a bad thing? As automation and robotics sweep through manufacturing, Smart Factories driven by digital information are slowly emerging as an ultra-lean answer to the skilled labor shortage and other competitive issues.

Is the robot revolution really such a bad thing? As automation and robotics sweep through manufacturing, Smart Factories driven by digital information are slowly emerging as an ultra-lean answer to the skilled labor shortage and other competitive issues.

As machine tool manufacturers work on enabling technology to make the Smart Factory possible, the field of machine service and support has started to drastically minimize the window of lost productive time that shops must deal with.

The average shop taking their first steps into automation doesn’t need to break the bank by investing in lights-out production with advanced robotics. There is a simpler, less expensive way to impact your bottom line.

Deliberately pull a die out of the stamping press for tool maintenance even though it is still producing perfect parts? That’s right. Don’t wait for that next emergency to shut everything down to put out fires. You can actually reduce downtime by regularly scheduling preventive tool maintenance that provides longer tool life, fewer scrapped parts and improved productivity.

Smart manufacturing tools are helping shops of all sizes deal with labor shortages and production inefficiencies. When implemented and managed correctly, these tools can aid human workers, create a more productive workforce and increase overall competitiveness.

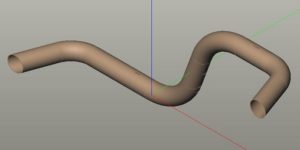

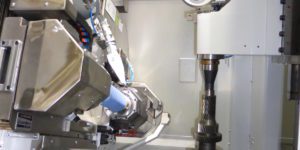

Fit-up, fixturing and assembly of multiple tubes can be difficult when coping, mitering and other secondary operations are required after bending. This is where new tube fabrication technology shines. Though it may bill out at a higher machine rate/hour, the time, material, tooling and labor it saves delivers a lower cost per assembly – and higher profitability.

The interest rate is a very small component of overall financing costs. It’s more important to match the lender to your overall financing needs. Here are some key factors that can help you find a good fit for a financing partner.

When the job involves high precision, grinding can be tough work. To make it a little easier – and more profitable – take a closer look at these new, versatile precision grinding machine tools.

When the job involves demanding fabrication, grinding can be tough work. To make it a little easier – and more profitable – take a closer look at these more powerful, longer running power tools.

Is the robot revolution really such a bad thing? As automation and robotics sweep through manufacturing, Smart Factories driven by digital information are slowly emerging as an ultra-lean answer to the skilled labor shortage and other competitive issues.

Is the robot revolution really such a bad thing? As automation and robotics sweep through manufacturing, Smart Factories driven by digital information are slowly emerging as an ultra-lean answer to the skilled labor shortage and other competitive issues.

Smart manufacturing tools are helping shops of all sizes deal with labor shortages and production inefficiencies. When implemented and managed correctly, these tools can aid human workers, create a more productive workforce and increase overall competitiveness.

The interest rate is a very small component of overall financing costs. It’s more important to match the lender to your overall financing needs. Here are some key factors that can help you find a good fit for a financing partner.

These advanced gas mixing, delivery and monitoring systems can help you reduce your gas consumption, ensure uniform gas flow and avoid contamination for a higher quality finished weld.

The problem may be as simple as a loose contact tip or something more complex, like incorrect TCP. Understanding the steps for proper troubleshooting helps narrow down potential causes, prevents replacement of components that don’t need replacing, and quickly gets you back to producing quality parts.

Smart manufacturing tools are helping shops of all sizes deal with labor shortages and production inefficiencies. When implemented and managed correctly, these tools can aid human workers, create a more productive workforce and increase overall competitiveness.

Without DoE, chemists would have taken twice as long to develop the extremely biostable HOCUT 8000 coolant and been lucky to achieve its same levels of performance in extending sump life and eliminating the need for costly sump-side additives. Here’s an inside look at how they did it.

A complete coolant recycling system can improve profits, tool life, workplace safety and regulatory compliance. Maximizing its effectiveness starts with the most important and essential piece of equipment, followed by three options for coolant management and monitoring.

Though scrap metal is often regarded as a waste or by-product from fabrication operations, it is actually a viable revenue source – in fact, it is the second largest revenue source next to the finished product. This is why shops should have a formal management system in place to maximize the revenue they generate from scrap.

As machine tool manufacturers work on enabling technology to make the Smart Factory possible, the field of machine service and support has started to drastically minimize the window of lost productive time that shops must deal with.

The Soft Grip Back Blow Safety Air Gun from EXAIR uses the smallest back blow nozzle available to deliver a blast of air to effectively blow debris and liquids from inside small pipe or hose diameters, channels, bores, holes, internal threads and other internal part features.

The Bench Grinder Safety Gauge from Rockford Systems ensures compliance with OSHA 1910.215 by making sure work-rests are kept adjusted to within 1/8 in of the wheel to prevent the workpiece from being jammed between the wheel and the rest and potentially breaking the wheel.

When the job involves high precision or demanding fabrication, grinding can be tough work. To make it a little easier – and more profitable – take a closer look at the latest advances in abrasives.

Precise cutting starts with preparation. Here are three tips to help you optimize performance and produce clean, smooth, straight cut lines in preparation for welding to minimize secondary operations like deburring and cleanup, and help operators achieve better weld penetration for higher quality welds.

Deliberately pull a die out of the stamping press for tool maintenance even though it is still producing perfect parts? That’s right. Don’t wait for that next emergency to shut everything down to put out fires. You can actually reduce downtime by regularly scheduling preventive tool maintenance that provides longer tool life, fewer scrapped parts and improved productivity.

When you absolutely, positively have to inspect jobs faster, take a closer look at these metrology systems.

Flexible, easy-to-install and affordable visual quality assurance systems can inspect every stage of production, using artificial intelligence to self-adapt and self-adjust to changes. After reviewing samples, they learn – without any human interaction – all of the part’s attributes, surface characteristics, etc. and begin inspecting in only a few minutes.