March 2020

Digital Issue

HIGH MIX, LOW VOLUME: Everyone's a Job Shop Now The days of low-variation, high-volume production are fast disappearing. With more customers avoiding unnecessary stocking by placing and repeating orders in smaller batch sizes, virtually all markets now demand made-to-order parts in smaller volumes. To remain profitable, manufacturers must implement machine tools, controls, software, tooling, sensors, accessories, and processes that facilitate quoting, minimize setup time, and optimize scheduling for full, nimble flexibility.

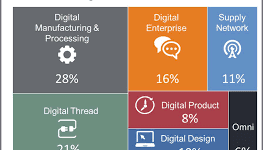

Subscribe View Digital IssueOverwhelmed about where and how to start digitizing? Relax. Rome wasn’t built in a day, either.

More fabricators are using larger-diameter grinding wheels and flap discs for their grinding, material removal, and blending applications instead of 4.5-inch options — and with good reason.

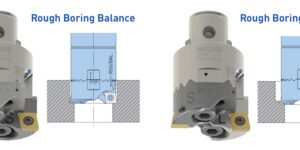

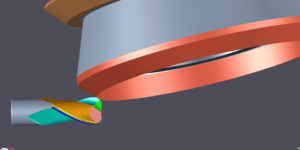

The rules for twin-bore roughing and single-point fine boring are similar – but not the same. Lead angles close to 90 degrees more effectively combat potentially damaging chatter and vibration because they apply the least amount of radial pressure against the tool.

When it couldn’t find an acceptable digital work instructions solution, CMP Advanced Mechanical Solutions in Quebec developed one in-house: Visual Knowledge Share (VKS). The spinoff business earned CMP a prestigious best-practices award from the provincial government.

A Nevada company became a single-source supplier after installing a fiber laser tube cutter and replacing a CO2 sheet cutter with a fiber laser cutter. With a fiscal year of April to April, B&J Inc. is on track to surpass its yearly sales goal by 20%.

Zetec’s manual Sweeper Scanner can replace multiple specialized scanners, lowering costs and reducing the amount of equipment needed to conduct inspections in oil and gas, aerospace, and other applications.

A Chinese components supplier is meeting the continuing strong demand for cars and trucks by using Schwarze-Robitec’s CNC 25 E TB MR and CNC 80 E TB MR tube benders to manufacture small-diameter parts more quickly and easily.

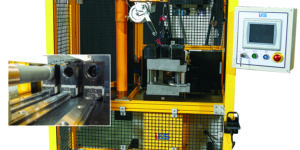

Innovative Engineered Solutions’ newest end former is a digitally controlled 3-hit, wide-vise ram machine. Featuring the FormPro II control system, the fully programmable machine allows the operator to select up to three progressive ram form hits in a single clamping.

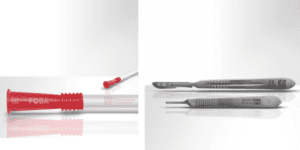

Used to temporarily block water and sewer pipes and drainage systems for low-pressure testing during maintenance and emergencies, single- and double-steel plugs from the Pipestoppers division of Huntingdon Fusion Techniques HFT are suitable for pipes ranging in diameter from 2 in to 48 in (50 mm to 1,200 mm).

Equipped with a variable-speed electric motor, Esco Tool’s portable but powerful Prepzilla bevels any angle, face, and bore simultaneously on-site or in the shop. A line of boiler tube expanders with universal pivoting extensions is also available.

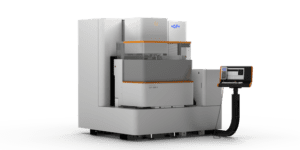

Bystronic’s ByTube 130 enables sheet metal fabricators to quickly and easily enter the tube-processing market. Available with 2kW or 3kW fiber laser power, the machine provides fast, flexible, and affordable processing for a wide range of materials and thicknesses in a fully automated workflow.

BLM Group’s compact E-Shape eliminates interference from overhead structures with a punch table that works horizontally. The LT8.20 allows users to choose their preferred laser source, loader/unloader style, and positioning of peripheral equipment to maximize floor space.

Transfluid’s T-bend system processes tubes up to 2.36 in (60 mm) with a bending radius of 1xD. Most have two or three bends, with the cut made straight after the last bend or between two bends. No additional follow-up cuts are required.

Disappointed with the quality and turnaround time of outsourced plating, Tube-Mac decided to bring the process in-house. Turnaround time fell more than 80%, from two weeks to two days. The manufacturer’s also no longer paying to ship components off-site for plating.

Greater robot payloads are opening the door to automatic fabrication of large, unwieldy components.

Handling products from 4 to 35 kg, two new robots emphasize safety, ease of use and reliability.

What with designing tombstone fixtures, selecting tooling, and programming the operations, the time and money required to buy and use a flexible manufacturing system (FMS) may be off-putting. But as this Massachusetts manufacturer learned, the investment brings peace of mind by providing financial stability.

QW Elite membership is designed to avert down time and ease the burden of a shrinking workforce. When used to its fullest potential, return on investment on the $995 annual subscription will occur on the first order.

Heidenhain Corp.’s Acu-Rite brand now offers one rugged and easy-to-use digital readout (DRO) platform for all common manual machines. The DRO300 series allows users to control a sinker EDM machine as well as grinding, milling, and turning machines.

Thanks to radio frequency identification (RFID) technology, AgieCharmilles CUT P operators will never run out of wire because they’ll know the available length of each SMART wire spool. Spools also check selected wire technology and adjust machine performance accordingly to optimize cutting.

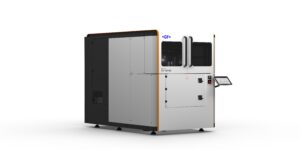

The AgieCharmilles FORM X 400 with System 3R WorkPartner 1+ from GF Machining Solutions speeds output by bringing all production technologies together in one process chain. Users also benefit from the updated control interface’s advanced levels of logic, speed, and safety.

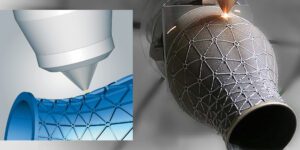

By blending horizontal wire orientation, a rotary axis, and an integrated basket to catch separated parts, the AgieCharmilles CUT AM 500 from GF Machining Solutions facilitates additive manufacturing (AM). The combination of features supports the part, allows for easy part handling, prevents part damage, and offers full automation readiness.

Two integrated features enable the AgieCharmilles CUT 2000 X wire EDM to provide unmatched accuracy and flexibility: GF Machining Solutions’ Intelligent Spark Protection System (ISPS) averts wire breakage by automatically unifying discharge distribution and Integrated Vision Unit (IVU) Advance automatically corrects machining errors.

Fast-hole electrical discharge machine (EDM) supplier offers a new CNC wire-cut machine, the S-EW3, at an affordable price. E-learning training software enhances user’s experience.

When it couldn’t find an acceptable digital work instructions solution, CMP Advanced Mechanical Solutions in Quebec developed one in-house: Visual Knowledge Share (VKS). The spinoff business earned CMP a prestigious best-practices award from the provincial government.

More than 50% of Clippard’s pneumatic valve and cylinder production is done via wire EDM. When Global Innovative Products (GIP) needed real-world validation of its testing on Plasma, a gamma-phase intermetallic zinc alloy-coated wire with brass core, Clippard successfully used the wire to produce tooling.

The difference between a skilled operator and an inexperienced one is night and day. Machine builders are helping manufacturers remain productive and profitable by deploying technologies that close the skills gap between dedicated operators with extensive knowledge of just one process and today’s jack of all trades.

In addition to several new tool types, the package reduces setup time from hours to 5 minutes via a new tool-balancing feature and provides an intuitive interface for creating complex endmill geometries that minimize chatter. For example, the constant-helix ballnose option is replaced by a graphical drag-and-drop designer with optimized irregular helix curves to reduce vibration and near-instant visualization by switching from 2D to 3D projection of the cutting edge.

Greater robot payloads are opening the door to automatic fabrication of large, unwieldy components.

FOBA will also display Titus, its new vector scan laser marking head, the smallest and lightest on the market.

The 15.6″ true-flat full-HD LCD from Marposs, with integrated touch screen, supplies operator information, rich color and crisp, detailed screen images.

Expect high productivity milling and turning for a wide array of part manufacturing.

Handling products from 4 to 35 kg, two new robots emphasize safety, ease of use and reliability.

Open Mind Technologies’ CAM software offers the ultimate in hybrid production: directed energy deposition (DED) or wire arc additive manufacturing (WAAM) and subtractive processing on one machine.

Xiris Automation products enable manufacturers to detect, recognize, and interpret quality defects. Just 0.87 in (22 mm) wide and weighing 0.22 lb (100g), the XVC-700 camera enables automation in spaces too small for traditional welding cameras.

Greater robot payloads are opening the door to automatic fabrication of large, unwieldy components.

Consider the process as a whole from start to finish. Activities before and after welding, such as part fit-up and post-weld grinding, affect how much time welders actually spend under the hood.

Handling products from 4 to 35 kg, two new robots emphasize safety, ease of use and reliability.

Handling products from 4 to 35 kg, two new robots emphasize safety, ease of use and reliability.

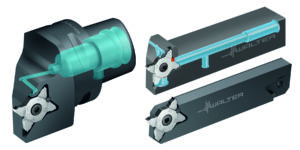

Walter USA products come in three designations: Perform indicates

an economical solution, Advance tools balance price and performance, Supreme indicates the highest level of technology and performance available. The MC232 Perform cutter’s corner radius improves approaches, tool life, and edge stability.

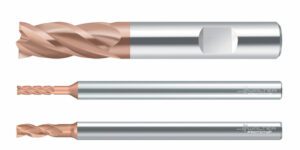

The ST540 5-flute solid carbide end mill is the latest addition to Seco Tools’ expanded Niagara Cutter Stabilizer product family. Together, they comprise an all-in-one solution for roughing and finishing that’s equally effective with all material types, from steel to cast iron and stainless steels to superalloys.

Schunk’s Kontec KSX-C power-assisted vise with continuously variable force adjustment ensures a secure hold event with minimal clamping surfaces. Fully encased spindle, drawbar extensions, and large jaw range enable the vise to adapt quickly and easily to any new requirement.

New geometry inserts are introduced for the CoroMill 311 from Sandvik Coromant. The latest additions will benefit the automotive, aerospace, and oil and gas sectors.

Along with extremely heat-resistant coatings and special carbide substrates, Mapal’s OptiMill-3D solid carbide milling cutters are characterized by the dimensions and geometries specifically adapted to mold making.

A 4-flute, solid carbide end mill delivers superior performance for steel, stainless steel, high-temperature alloys, and cast iron. A 5-flute end mill maximizes aluminum roughing for aerospace machining.

Parabolic performance cutting (PPC) product family expanded to include copy milling cutters with indexable insert; PPC solid carbide barrel milling cutters optimized for high-alloy and hardened steels.

Dormer Pramet adds to its milling assortment for die and mold with the double-sided SNGX11 insert for machining corners inside a pocket and SSN11 cutter available in diameters from 1.26 in to 4.92 in.

The latest addition to Dapra Corp.’s EDGE² SBN finishing system, SBD inserts are designed to help operators finish back draft jobs more accurately and with fewer insert changes. Available in two premium coatings, they’re interchangeable with SBN series twin-edge ball nose inserts.

The company is manufacturing basic arbors (shell mill holders, end mill holders, shrink fit, and blanks) in inch sizes for the North American market. Three new accessories increase in-process efficiency by automatically cleaning workstations and workpieces.

More fabricators are using larger-diameter grinding wheels and flap discs for their grinding, material removal, and blending applications instead of 4.5-inch options — and with good reason.

In addition to several new tool types, the package reduces setup time from hours to 5 minutes via a new tool-balancing feature and provides an intuitive interface for creating complex endmill geometries that minimize chatter. For example, the constant-helix ballnose option is replaced by a graphical drag-and-drop designer with optimized irregular helix curves to reduce vibration and near-instant visualization by switching from 2D to 3D projection of the cutting edge.

The increasing demands placed on cutting technology are leading to an increased need for more advanced machine tools. Engineers in Germany have automated a magazine capable of storing and deploying up to 9,000 tools using PC-based control, EtherCAT, and dynamic motion control.

The rules for twin-bore roughing and single-point fine boring are similar – but not the same. Lead angles close to 90 degrees more effectively combat potentially damaging chatter and vibration because they apply the least amount of radial pressure against the tool.

Annual installations of collaborative robots (cobots) grew 23% from 2017 to 2018, according to the World Robotics Report, published by International Federation of Robotics.

Walter expands its MX system with Walter Capto toolholders, opening a new range of applications.

Fowler High Precision and Verisurf Software partner to offer a lightweight direct computer control (DCC) coordinate measuring machine (CMM) loaded with zCAT software. Because the combination enables in-process inspection, the same employee making the part can now measure the part.

The multisensor MiSCAN Vision System is a coordinate measuring machine (CMM) with a microscopic-level scanning probe. The compact MiSTAR 555 is a space-saving in-line or near-line CNC CMM designed for high-speed, high-accuracy measurements with assurance from 10° C to 40° C.

Hexagon’s Leitz Reference BX coordinate measuring machine (CMM) accelerates blade and glass measurement up to 50%, addressing long-standing challenges faced by aAerospace and consumer electronics manufacturers. Multisensor 3D OPTIV M CMM gives manufacturers of small and medium precision parts greater configuration flexibility.

The Metrology Services Division of Automated Precision Inc. (API) is renting Radian laser trackers with accessories by the day, week, month, or longer. The portable coordinate measuring machines (CMMs) are supplied complete with metrology software or customers can use their own measurement software license.

The Hungarian automotive control system manufacturer Continental processes 1,500 inspection reports every year. Cycle times are twice as fast with a LK Metrology ALTERA 8.7.6 coordinate measuring machine (CMMs) that has a laser scanner and a touch probe.

The 15.6″ true-flat full-HD LCD from Marposs, with integrated touch screen, supplies operator information, rich color and crisp, detailed screen images.