March 2021

Digital Issue

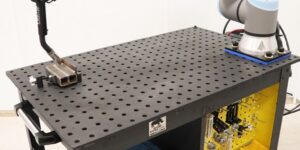

Perfecting the Partnership: Optimizing the Human/Cobot Interference. Collaborative robots (cobots) are easier to integrate into manufacturing operations because their ability to see and learn makes them easier to program than industrial robots. Pairing humans and machines adds a personal touch to opportunities in manufacturing. They'll boost throughput more by communicating directly with their human coworkers on welding, assembling, and other processes.

Subscribe View Digital IssueConnecticut mold maker Ray Coombs put capital investment on hold for five years to work with the local educational and manufacturing communities to solve his labor problems once and for all. Then he added three new machines that are helping to cross-train employees for record sales.

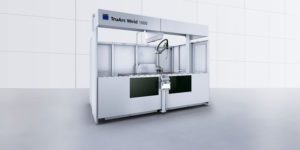

Cobotic welding systems occupy the gap between fast and heavy industrial robots and manual welding. They also challenge the paradigm that welding automation is strictly a high-volume game.

Circular machining with low radial engagement and constant feed per tooth extends tool life by minimizing heat and vibration when machining extremely hard materials. CAM and control developers are making it easier for any size shop to add this technique to their capabilities.

Connecticut mold maker Ray Coombs put capital investment on hold for five years to work with the local educational and manufacturing communities to solve his labor problems once and for all. Then he added three new machines that are helping to cross-train employees for record sales.

Last year’s unprecedented economic and supply chain challenges underscored gaps in commonsense contingency planning. Manufacturers that take heed of these lessons learned will be better prepared for whatever crisis may arise.

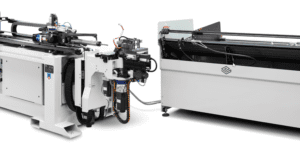

Available in two versions with varying levels of functionality, transfluid’s Windows-based t project software links geometry and material data to achieve precise bending results.

Two models – the 2.5 and 4.0 – from Kaast Machine Tools ensure consistently accurate strength-promoting beads in materials up to 0.15-inch (4mm) thick. Available with mechanically (ZSM) or hydraulically (ZSH) driven upper rolls.

IRMCO Advanced Metalforming Lubricant Technologies’ iNSIGHT enables metal stampers to track the rate of chemical consumption by part and process and compare the data to tool life to pinpoint the actual cost per part for each process in a facility.

Two standard models – the eRB80 TS and eRB150 TS – electric upcut tube saws from Innovative Engineered Solutions (iES) cut diameters up to 3.5 inches (90mm) and 5.9 inches (150mm), respectively.

HGG Profiling Equipment’s ProCutter900 RB increases throughput by continuously feeding, cutting and profiling, and moving pipe out. The small-footprint machine’s accuracy dramatically reduces post-cutting grinding, fitting and welding time.

An automated version of Glebar’s TF-9BHD infeed/thrufeed centerless grinder, the TF-9D features the widest work wheel on the market. Customizable interface designed for automation and 8-5/8-inch-wide work wheel combine to increase throughput.

Featuring a compact layout, integrated loading/unloading capability, and easy-to-use programming software, BLM Group’s Smart Bender enables an operator to go from design to part in one click and walk away.

Even though they have two arms, Kawasaki Robotics’ duAro cobots fit into a single-person space while providing enough room for an employee to safely work alongside. Two models provide 8.8- and 13-pound payloads.

The “A” in Hanwha’s HCR-3A, HCR-5A, and HCR-12A stands for “advanced.” Three cobot models improve on their predecessors by offering customizable solution packages that incorporate artificial intelligence and mobility technologies.

Delmia Robotics’ software from Dassault Systemes maximizes automation initiatives by enabling manufacturers to design and virtually test a drilling-and-riveting, arc welding, spot welding, and/or material handling line before rolling it out.

Do you own a Fanuc CRX cobot? Thinking of buying one? ATI Industrial Automation’s end-effector kits make the most of your investment by enabling applications including deburring, orbital sanding, tool changing, and force/torque sensing.

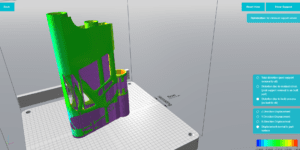

In its drive to develop an end-to-end solution for additive manufacturing, Siemens Digital Industries Software offers tools that simulate the printing process at various levels. To minimize the expensive quality-refinement process, modules identify and correct areas of malformation and shrinkage.

The OB7-Stretch from Productive Robotics extends 1.25 meters, but with a payload of 4kg, it offers an affordable alternative to bigger-payload, long-reach cobots. Its seven axes design gives it a dexterity with which to circumvent obstacles.

Handling products from 4 to 35 kg, two new robots emphasize safety, ease of use and reliability.

An economical option for small shops that need a second machine or additional spindle, all three models of Palmgren’s vertical machining centers (VMCs) have a 10-tool magazine with automatic changer and user-friendly portable handwheel.

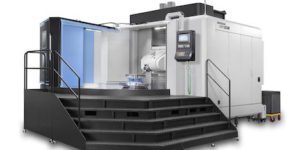

Ideal for the demanding aircraft, automobile, power generator, mold-and-die, and semiconductor industries, Niigata’s 5-axis HN80E-5X horizontal machining center (HMC) produces 1.65-ton parts almost 50 inches in diameter and 40 inches high.

Engineered for tight-tolerance work for the mold and die, aerospace, and energy industries, Mitsui Seiki’s compact Vertex 100 provides a large workpiece capacity so operators can process a wider range of parts.

Mazak’s VC-Ez 20 is the first of three vertical machining centers (VMCs) that offer much the same functionality and performance as previous models, but in a more compact and more affordable package.

Thanks to a 75% increase in work envelope and high traverse rates, Matsuura USA’s MAM72-52V processes larger-diameter and heavier workpieces than its predecessor. Integrated tower pallet enables lights-out production.

With Quick and Simple Startup of Robotization (QSSR), Fanuc simplifies the process of connecting and programming a Fanuc robot or cobot. The all-in-one package enables operators to program the robot using the machine’s CNC.

Doosan’s DHF 8000ST is a single-table version of the company’s DHF 8000 5-axis horizontal machining center (HMC) that incorporates a turning function so manufacturers can save time by moving from roughing to finishing with one setup.

Available in 4- and 5-axis versions, Chiron’s dual-spindle DZ 22 has a fast spindle for machining aluminum and aluminum alloy workpieces and a strong spindle for machining hard materials and large tools.

Do you own a Fanuc CRX cobot? Thinking of buying one? ATI Industrial Automation’s end-effector kits make the most of your investment by enabling applications including deburring, orbital sanding, tool changing, and force/torque sensing.

Circular machining with low radial engagement and constant feed per tooth extends tool life by minimizing heat and vibration when machining extremely hard materials. CAM and control developers are making it easier for any size shop to add this technique to their capabilities.

The OB7-Stretch from Productive Robotics extends 1.25 meters, but with a payload of 4kg, it offers an affordable alternative to bigger-payload, long-reach cobots. Its seven axes design gives it a dexterity with which to circumvent obstacles.

Handling products from 4 to 35 kg, two new robots emphasize safety, ease of use and reliability.

Tolomatic’s CSW and CSWX Compact ServoWeld welding gun actuators for robotic spot welding integrate a 3,507-lbf and 4,047-lbf, respectively, actuator into a hollow-core servo motor for faster resistant spot-weld cycles.

Requiring just 4 square feet of shop floor space, Novarc Technologies’ spool welding robot (SWR) enables inexperienced welders working on pipe spools up to 30 feet long to monitor and adjust parameters to pipe variations in real time.

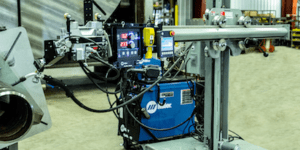

Lincoln Electric’s Fab-Pak Cobot Cart enables small- and medium-sized fabricators to justify investing in automation by providing a mobile, easy-to-program, and safe robotic welding solution.

Koike Aronson Ransome’s pipe-welding package incorporates the Cricket-I manipulator. Providing 20-IPM lift speed and 150-pound load capacity, the manipulator ensures productivity increases without sacrificing floor space.

Fanuc adds 15- and 33-pound-payload welding cobots to the ARC Mate product line. The arc welding cobots’ easy-to-program interface supports both simple and complex applications using advanced features.

ESAB and Yaskawa have partnered to offer small-to-medium-sized manufacturers and fabricators a pre-engineered welding cell that’s easy to set up and operate: the XCellerator.

Bystronic is selling three robotic welding options – Micro Cell, Compact Cell and Compact System – in the U.S. They’re configured by the German manufacturer Cloos Robotic Welding, which handles installation, training, and service.

Even though they have two arms, Kawasaki Robotics’ duAro cobots fit into a single-person space while providing enough room for an employee to safely work alongside. Two models provide 8.8- and 13-pound payloads.

The “A” in Hanwha’s HCR-3A, HCR-5A, and HCR-12A stands for “advanced.” Three cobot models improve on their predecessors by offering customizable solution packages that incorporate artificial intelligence and mobility technologies.

Delmia Robotics’ software from Dassault Systemes maximizes automation initiatives by enabling manufacturers to design and virtually test a drilling-and-riveting, arc welding, spot welding, and/or material handling line before rolling it out.

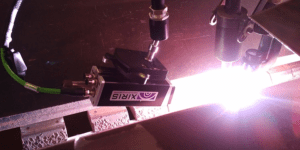

Cobotic welding systems occupy the gap between fast and heavy industrial robots and manual welding. They also challenge the paradigm that welding automation is strictly a high-volume game.

Multipass welds are often required in pipeline, ship, heavy-duty structural and pressure vessel construction. Selecting the proper abrasives and cleaning properly between each pass can help optimize results, saving the operation time and money.

A collaborative robot (cobot) welds more efficiently, more consistently, and has a longer reach than its human counterparts. Here’s what to consider as you shop for a model that will boost your operation’s throughput and quality.

A factory has many moving parts and processes. Connecting welding data to up- and downstream processes makes identifying the source of manufacturing problems easier and uncovers true costs across the entire operation.

Handling products from 4 to 35 kg, two new robots emphasize safety, ease of use and reliability.

Powered by a UR10e collaborative robot from Universal Robots, the Vectis Cobot Welding Tool from Vectis Automation is a low-risk, low-cost, easy-to-use system that boosts productivity by reducing the learning curve, deployment time and cost of robotic welding.

The rugged XVC-1000e weld camera from Xiris monitors MIG/MAG, TIG, plasma, laser or stick welding in exceptional detail from up to 100 m away.

IRMCO Advanced Metalforming Lubricant Technologies’ iNSIGHT enables metal stampers to track the rate of chemical consumption by part and process and compare the data to tool life to pinpoint the actual cost per part for each process in a facility.

Formulators spend significant resources to develop coolant that optimizes a machining process based on what materials, machine, and tooling a manufacturer is using. Don’t miss out on the product’s strategic value by being pennywise and pound-foolish.

Handling products from 4 to 35 kg, two new robots emphasize safety, ease of use and reliability.

Strong Hand Tools’ universal vises quickly and securely clamp stock of different thicknesses at multiple angles into place. They can be removed from the base and used separately.

Schunk’s Tandem PGS3-LH 100 clamping force block for basic aluminum and plastics machining has an integrated flange and comes with a console plate for easy mounting to machining tables, dividing heads, and clamping stations.

Comprising self-centering vises, quick-change bases and mounting accessories, Mate Precision Technologies’ 52/96 zero-point product line can be used for inspection, CMM, cleaning, washing, assembly, and additive manufacturing as well as on 3-, 4- and 5-axis machining centers.

Kurt Workholding replaces HP-model vises with Precision Force (PF) MaxLock vises featuring a patented locking mechanism that holds parts securely, keeps them square with excellent repeatability, and are affordable.

The toolholder for Horn USA’s Supermini grooving and boring tools applies a tensioning wedge to the insert’s face rather than circumference, increasing rigidity and repeatability.

Dillon Manufacturing can manufacture soft or hard and full-grip special top jaws in a wide range of materials and configurations to ensure chucks provide maximum grip for an application.

Destaco combined the best features of pneumatic swing clamps and straight line action clamps to create a low-cost workholding option for fixture builders. The manually actuated swing clamps eliminate the need for air.

Do you own a Fanuc CRX cobot? Thinking of buying one? ATI Industrial Automation’s end-effector kits make the most of your investment by enabling applications including deburring, orbital sanding, tool changing, and force/torque sensing.

Multipass welds are often required in pipeline, ship, heavy-duty structural and pressure vessel construction. Selecting the proper abrasives and cleaning properly between each pass can help optimize results, saving the operation time and money.

Smaller and lighter than other laser-induced breakdown spectroscopy (LIBS) analyzers, Rigaku Analytical Devices’ KT-100S identifies difficult materials including low-alloy steels, stainless steels, high-temperature alloys and lithium.

The 38DL Plus with 38-Link wireless adaptor for connecting to the Olympus Scientific Cloud (OSC) saves time and money by minimizing human error and optimizing data management.

LMI Corp.’s LaserGage HS742 3D sensor is a 3D laser profiler and that uses blue-laser technology and application-specific algorithms to overcome the challenge of measuring countersinks on solid, translucent, shiny, and opaque surfaces with repeatable results.

Ametek’s Chatillon DFS II Series digital force gage with ForceTest 2.0 software gives the operator a highly flexible testing system while additional functionality. The operator also benefits from live test graphs and data analysis.

Designed for Universal Robots’ UR3e cobot arm, the Q-Span Workstation from New Scale Robotics comes with everything necessary to automate small-part measurement inspection. You can improve gage R&R and boost capacity without adding headcount.

Some manufacturers shy away from conducting gage repeatability and reproducibility (GR&R) studies because the results are inconsistent. But because variability is unavoidable, your goal is to calibrate that measuring device to consistently return an acceptable range of results.

The rugged XVC-1000e weld camera from Xiris monitors MIG/MAG, TIG, plasma, laser or stick welding in exceptional detail from up to 100 m away.