March 2023

Digital Issue

Next Level Sawing & Finishing: Are you ready to take things up a notch regarding your fabrication and finishing processes? Your supplier partners are assisting through regular collaboration with customers to not only understand but solve their problems and challenges. For instance, easy to use, efficient sawing systems are essential in delivering precise and accurate cuts that can slice through the toughest of materials, and in high volumes. Add to that time-saving finishing solutions with high metal removal rates and features such as anti-chip abrasive technology, and ergonomically friendly products, as examples, which are indispensable in keeping projects on schedule and workers safe and satisfied in a tight labor market. Get to know the latest products that will support the elevation of your processes.

Subscribe View Digital IssueSandvik Coromant’s CoroDrill® 462 and CoroDrill® 862 mark a new era for micro drilling of difficult-to-machine materials.

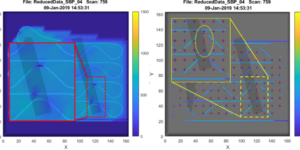

Fabrisonic’s new SmartPlate™ includes embedded sensors made to a customer’s specifications. Extract data from the sensors for real-time or post-processing analysis.

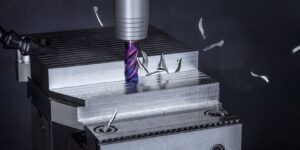

No matter what your project calls for, there is an advanced cutting equipment solution to enhance and expand your metal fabrication capabilities.

Cyber threats continue to fly under the metalworking industry’s radar as a major business disruptor. It’s time to ensure the allocation of resources to prevent these threats becomes a priority.

Building a relationship with a secondary financial partner keeps your business in a healthy financial position should your primary partner discontinue your relationship.

Electric vehicle related and advanced energy expansion project announcements, among others, hint at an economic surge.

Fabrisonic’s new SmartPlate™ includes embedded sensors made to a customer’s specifications. Extract data from the sensors for real-time or post-processing analysis.

No matter what your project calls for, there is an advanced cutting equipment solution to enhance and expand your metal fabrication capabilities.

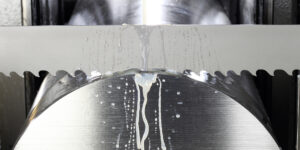

Breakthroughs in the development of robust sawing systems ensures your shop will exceed your customers’ most challenging and unique demands.

Aggressively (but safely) and rapidly remove material and achieve precise cuts thanks to breakthroughs in surface finishing products. Electronic dosing systems ensure meticulous paint applications.

Heat treating is an essential process in the development of components for a wide range of industries.

Sandvik Coromant’s CoroDrill® 462 and CoroDrill® 862 mark a new era for micro drilling of difficult-to-machine materials.

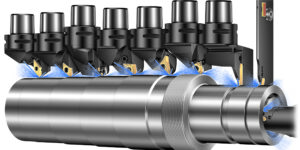

The speed, versatility, flexibility and precision of multi-axis machines supports a wide range of industries and part sizes.

Fabrisonic’s new SmartPlate™ includes embedded sensors made to a customer’s specifications. Extract data from the sensors for real-time or post-processing analysis.

Metal fabricators will find no shortage of advanced and readily available resistance welders to meet their needs.

Selecting the right shielding gas is vital to gaining good weld quality and minimizing unnecessary downtime.

AMADA WELD TECH’S Mark Boyle answers questions about the resistance welding processes.

Cyber threats continue to fly under the metalworking industry’s radar as a major business disruptor. It’s time to ensure the allocation of resources to prevent these threats becomes a priority.

Sandvik Coromant’s CoroDrill® 462 and CoroDrill® 862 mark a new era for micro drilling of difficult-to-machine materials.

Aggressively (but safely) and rapidly remove material and achieve precise cuts thanks to breakthroughs in surface finishing products. Electronic dosing systems ensure meticulous paint applications.

Increase uptime and operator satisfaction thanks to the latest improvements regarding chucks, collets and quick-change tools.

CERATIZIT USA Inc. is making quite a name for itself in the United States thanks to its expansive cutting tool portfolio and cutting-edge application engineering support.

Prepare for the changes the addition of a 5-axis machine will bring to your business with the right workholding and tool holder solutions.

Leading edge equipment, technologies and software provide a detailed look into the health and condition of cutting tools.