March 2024

Digital Issue

Smart Sawing, Cutting & Finishing: Precision, reliability, and efficiency in sawing, cutting and finishing systems are not just benchmarks but imperatives in metalworking shops, where every cut matters. Users depend on suppliers to provide dependable, durable, versatile, and where appropriate, automated solutions. They are in search of equipment that not only ensures speed, accuracy and ease of use — they also want a favorable price point. This issue features the latest in cutting and finishing tools and systems, where precision meets reliability.

Subscribe View Digital IssueThrough ease of use and increases in simplicity, CAD/CAM software is equipped with powerful features to meet the complex requirements of the metalworking industry.

There are many initiatives and programs in operation when it comes to solving the manufacturing workforce shortage, which is at a critical point. By 2030, 4 million manufacturing jobs will likely be needed, and 2.1 million jobs are expected to…

Robotic welding systems deliver fine-tuned programming to ensure the accuracy, speed and repeatability needed for high-quality welds.

Through ease of use and increases in simplicity, CAD/CAM software is equipped with powerful features to meet the complex requirements of the metalworking industry.

Produce simple to complex parts with accuracy, precision and consistency.

It is a very satisfying experience when you arrive at the end of a well-planned and implemented integration project.

For fabricators in search of new opportunities, and for customers who want shops that provide greater value, waterjet cutting is too important to overlook.

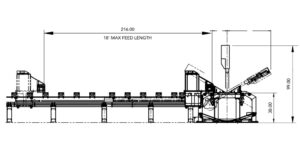

Investing in cutting systems driven by advanced automation capabilities and intuitive controls is a strategic move for fabricators looking to boost performance, manage waste and reduce costs. Laser Cutting Machine Outperforms Higher Wattage Lasers at Lower Operating Cost AMADA AMERICA…

A wide range of industry sectors benefit by embracing newly developed products to elevate their metal removal and finishing processes.

Real time monitoring systems track the performance of band saws, correcting the process to minimize disruptions.

Shops struggling with outside disruption and competitive pressures should look into robotic automation as these techniques continue to make significant advancements.

Through ease of use and increases in simplicity, CAD/CAM software is equipped with powerful features to meet the complex requirements of the metalworking industry.

High performance multi-axis machines and their supporting automation components provide consistency in metal-cutting processes.

It is a very satisfying experience when you arrive at the end of a well-planned and implemented integration project.

Real time monitoring systems track the performance of band saws, correcting the process to minimize disruptions.

Machine tending products, led by cobots, tackle repeatable tasks without compromising quality production, as well as operator safety.

Shops struggling with outside disruption and competitive pressures should look into robotic automation as these techniques continue to make significant advancements.

Robotic welding systems deliver fine-tuned programming to ensure the accuracy, speed and repeatability needed for high-quality welds.

Breakthrough developments display ongoing innovation in the welding sector, which leverages technologies such as AI and cobots.

Robotic tool changers respond promptly to your shop’s varying production needs, enhancing overall throughput.

Make timely decisions regarding tool changes and adjustments to machining parameters with powerful monitoring systems.