May 2012

There is no place for certainty in a business world that is in a constant state of flux. Doing everything right today in marketing and sales offers no comfort . . . because the needs and opportunities of tomorrow will be even more demanding.

Punch machines now do much more than simply punch holes. Today it’s all about completing multiple processes on the same machine, such as making up to one inch high flanges, tapping holes, forming, extruding, ribbing, offsetting, removing burrs from parts and more.

Mike Riley reports how the recent DoD agreement between Lockheed Martin and Sciaty points to EBDM as a promising new technology that could potentially change the world of machining high-value parts.

Punch machines now do much more than simply punch holes. Today it’s all about completing multiple processes on the same machine, such as making up to one inch high flanges, tapping holes, forming, extruding, ribbing, offsetting, removing burrs from parts and more.

Here is an outline of the various functions of perforated metals, the impact of punching on a metal’s properties and the difficulties of punching for a non-expert.

As versatile as the ironworker is, it is still possible to purchase the wrong machine – or at least not the best one – for your application. Here are some reasons why careful examination of these factors will prevent that from happening.

3-Dimensional Services used unconventional single part and low volume production technology to bring a game changing lighting system to market that also aids the environment.

Mike Riley reports how the recent DoD agreement between Lockheed Martin and Sciaty points to EBDM as a promising new technology that could potentially change the world of machining high-value parts.

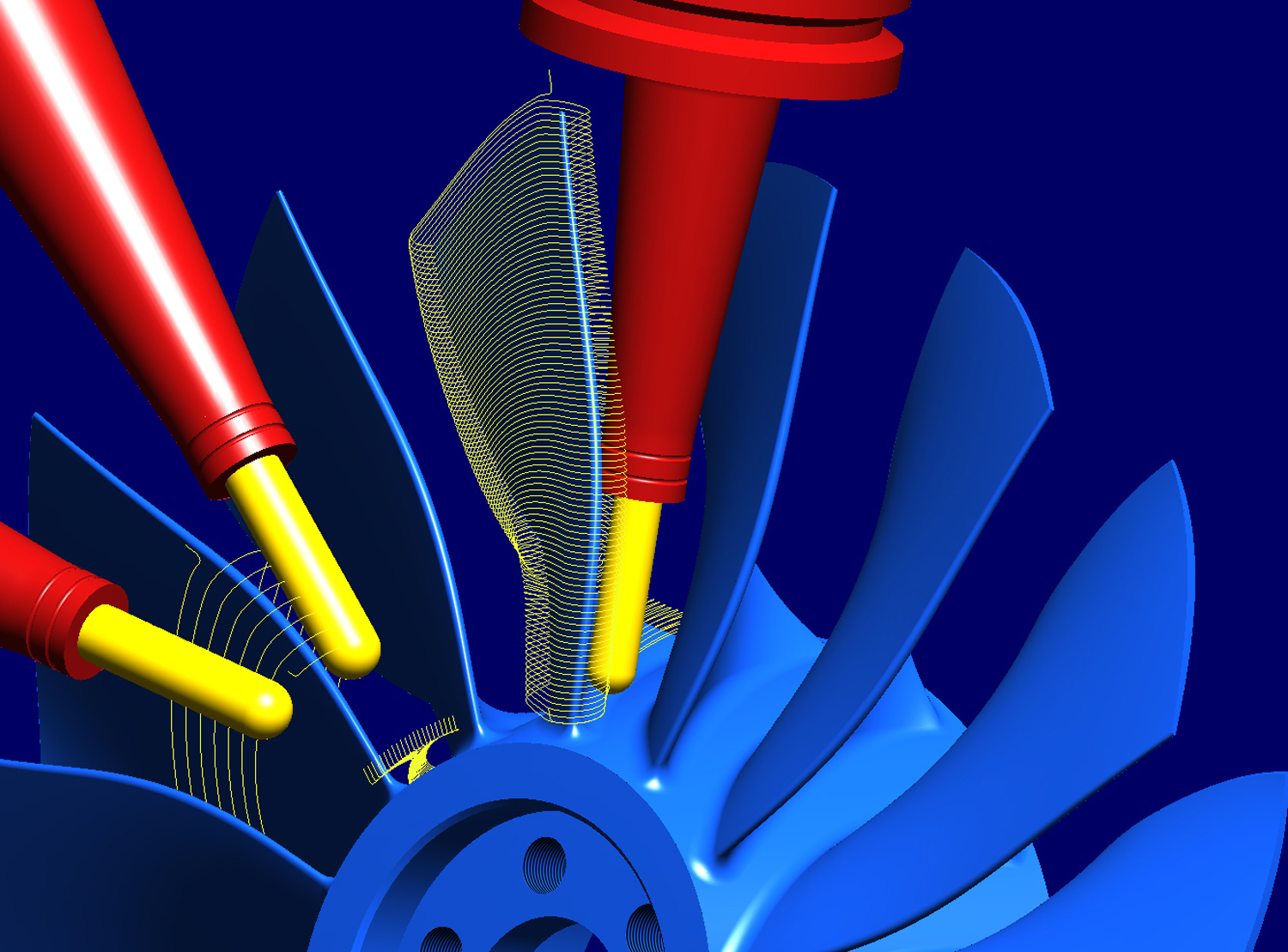

And what drives machining growth? Aerodyn Engineering uses intuitive 5-axis CAM software from OPEN MIND Technologies that “gets it.”

There is no place for certainty in a business world that is in a constant state of flux. Doing everything right today in marketing and sales offers no comfort . . . because the needs and opportunities of tomorrow will be even more demanding.

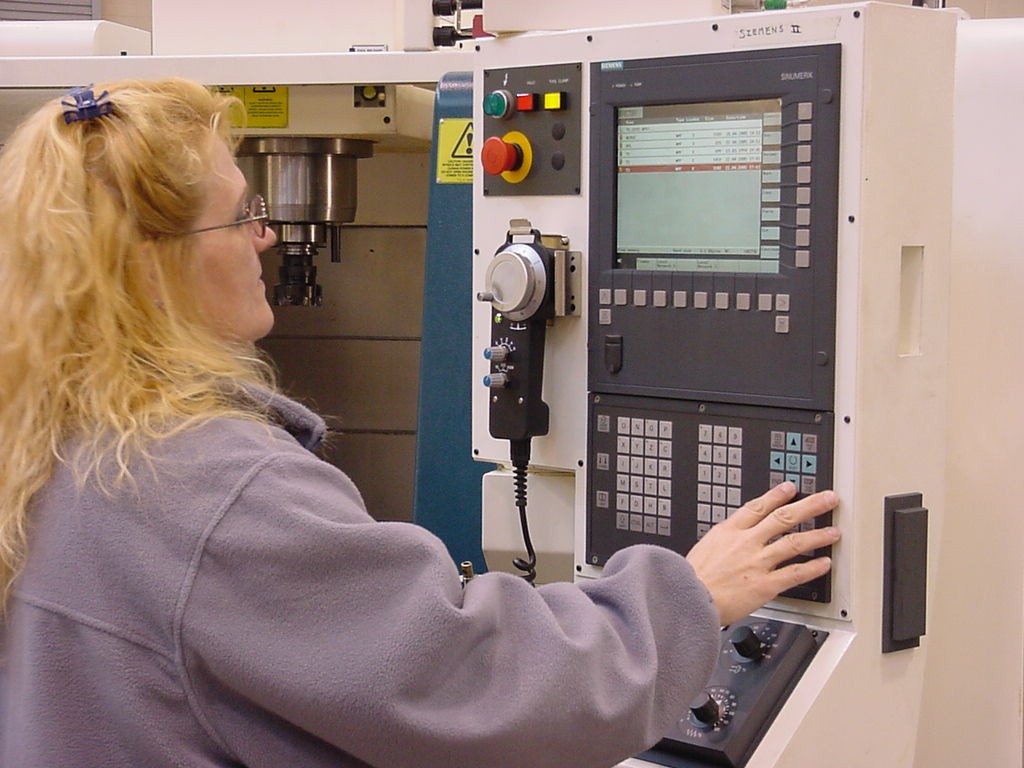

A Win-Win Situation: Machine tool builder EMAG uses the same Siemens Sinumerik 840D CNC and remote monitoring on all of the turning, grinding and turn/grind machines it sells to a major agricultural equipment manufacturer, resulting in substantial savings for both the customer and the supplier.

Defense contractor McNally Industries uses cost-estimating software from MTI Systems to better streamline their cost-estimating process, increase estimating speed, and enhance the accuracy of their quotations.

Ideal for manufacturing catheters, scalpels, saws, and screens, electropolishing systems from Technic Inc. process parts from millimeters up to 20 in square with superior part-to-part uniformity over batch methods, with better throughput on stainless steels, Monel®, Hastelloy®, titanium and related metals.

The number of experienced machinists in the U.S. is declining, but all shops that seek operator efficiency can still achieve it through the education programs offered by machine builders and control suppliers alike.

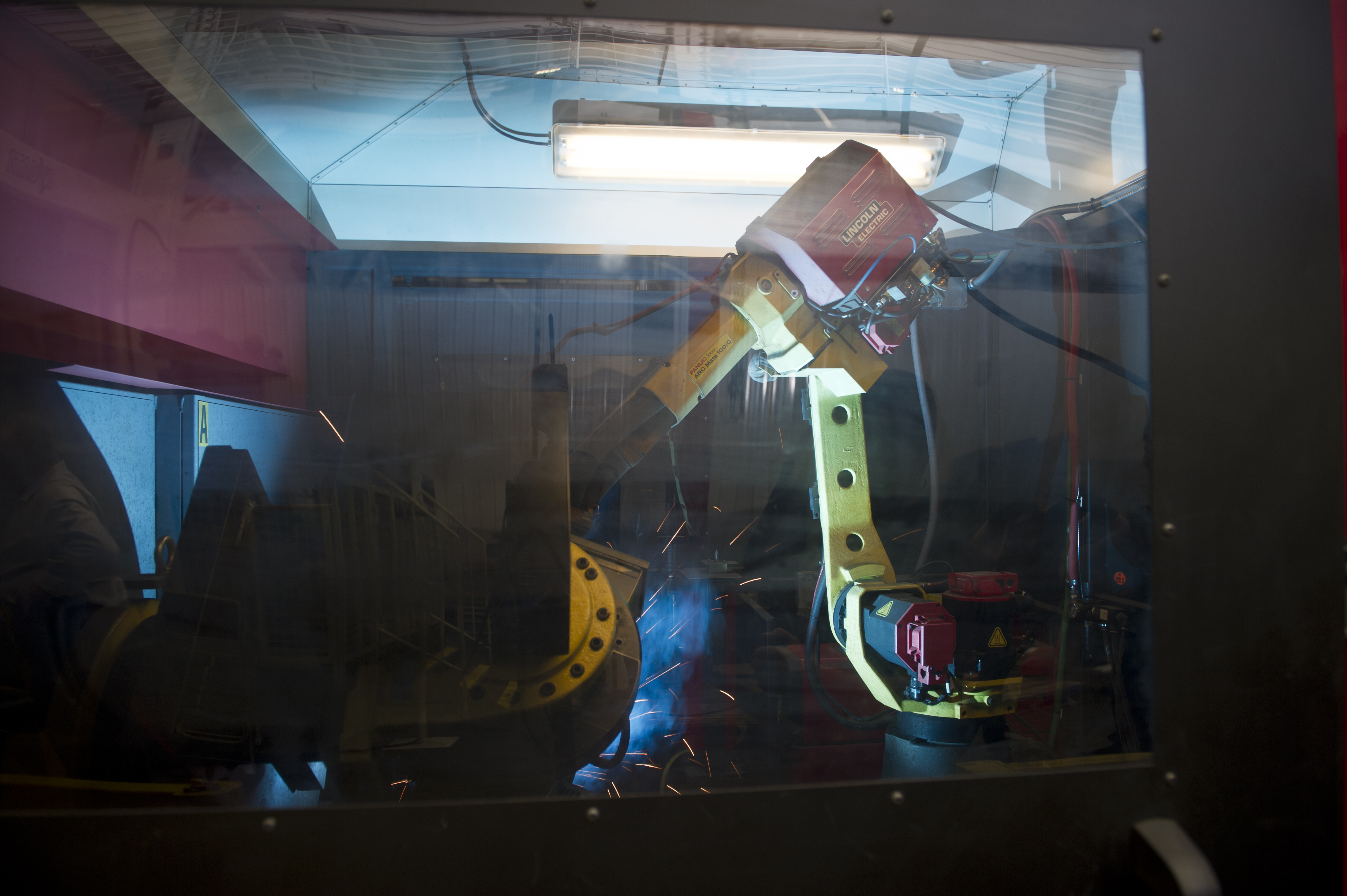

The Franklin plant of mining equipment manufacturer Joy Mining increased productivity and reduced costs in their bit block assembly by converting to automated welding systems from Lincoln Electric.

Georg Fischer Automotive uses an innovative resistance spot-welding process from Fronius to join die-cast aluminium parts in the vehicle door-frame on the Porsche Panamera.

Take a look at how contract manufacturer K-zell Metals can diversify and compete against global competition by bidding and planning fabrication work more aggressively with its increased capabilities and automation flexibility.

In developing this welding procedure, here’s how to look for the “keyhole” that is visible behind the arc and making sure that arc does not ride on top of the puddle.

TIG welding equipment from Lincoln Electric is used to reconstruct this vintage auto gem into a modern hot rod reincarnation at the hands of noted designer Murray Pfaff and his skilled crew.

More Power to You: When Helec Corporation retrofitted a workhorse MAG turning center with a new Fanuc CNC and AC digital axis drives/motors and spindle, it utterly brought new life to the entire shop floor.

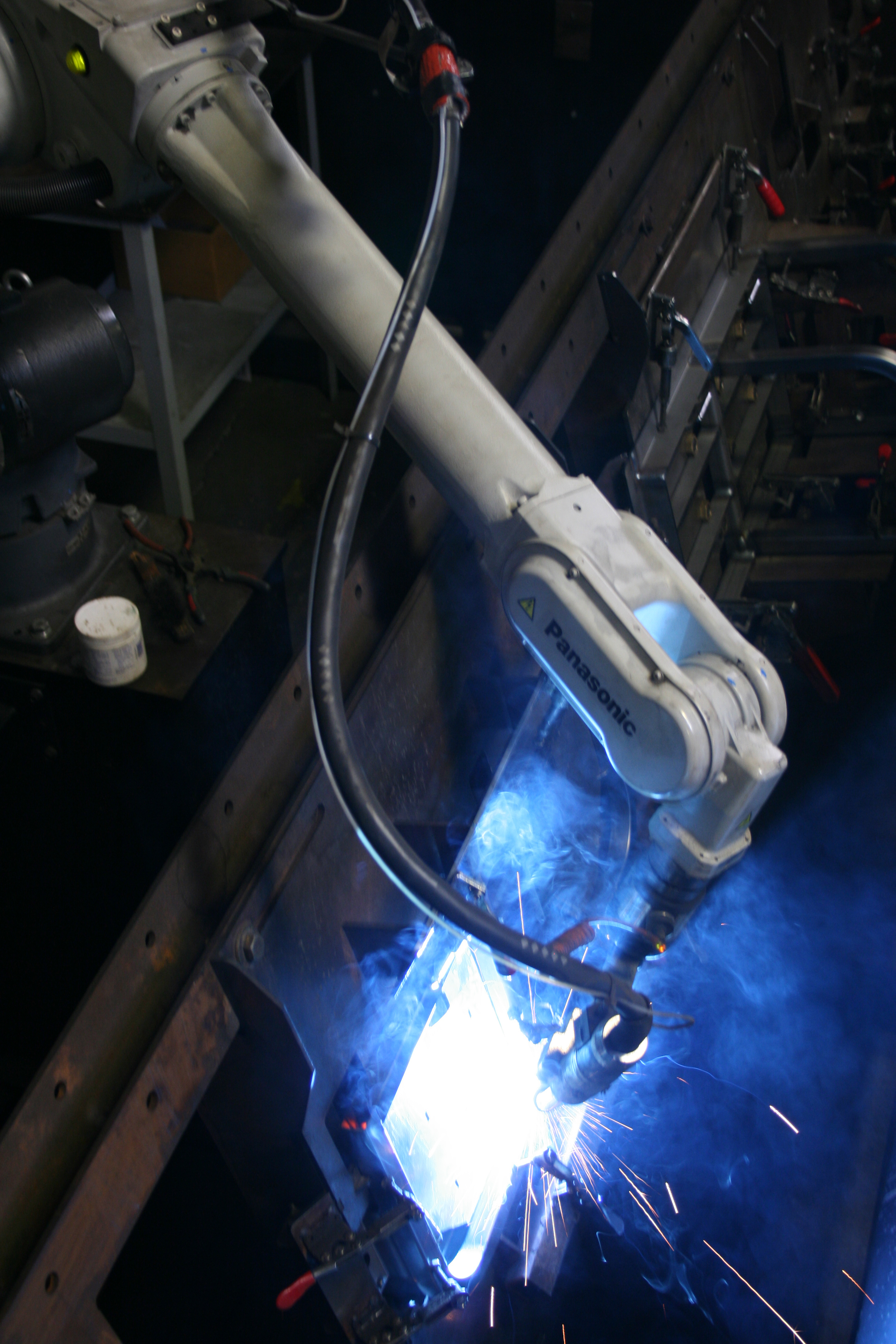

The robotic MIG gun and its consumables are frequently overlooked components in the system, but this maintenance primer from Tregaskiss shows that they are relatively easy to maintain and, by doing so, can positively contribute to the efficiency of the entire welding operation.

Steel distributor Aaron & Son used technology from Big Ass Fan Company in their New Jersey warehouse to overcome uneven ambient temperatures that created potentially disastrous condensation for their sweating steel inventory inside a non-air conditioned warehouse.

Phil La Duke of Rockford Greene International continues his look at the various specialties within the Safety function by exploring a role focused on maintaining regulatory compliance, protecting the workers, environment, and in some cases the products from coming into contact with hazardous chemicals.

CAM2 Gage 2.2 contact measurement software from FARO Technologies makes the FaroArm and FARO Gage even better, with more than 30 new features.

Let the Good Times Roll: At the Maryville plant of Kawasaki, Renishaw 5-axis scanning probes now collect data and reduce feedback to machining cells from hours to minutes and may ultimately eliminate the inspection systems for gears and cam lifts.