May 2017

Digital Issue

A prescription is a recommended set of instructions that govern the diagnosis and improvement of a condition. In this issue, we prescribe some of the latest metal forming and fabrication, welding, metal cutting, tooling and inspection technologies that can help shops diagnose and improve their current operations, including:

- Roll Forming: The Pre-Cut Vs. Post-Cut Dilemma

- Signs Your MIG Gun is Overheating – and How to Prevent It

- NAFTA Renegotiation: Are You Prepared?

- EASTEC 2017

Sometimes it’s equally as important to know what not to do as it is to know what to do. When it comes to investing in roll forming equipment and accessories, quality roll tooling designers must consider the possibilities for each customer.

Gun overheating can be a symptom of numerous problems, and it can result in catastrophic failure if ignored. Here are some common signs and causes of MIG gun overheating to be aware of that can help you prevent or quickly remedy the problem.

Knowing how to utilize the increased flexibility gained through laser welding can enable a fabrication shop to tackle tough challenges and creatively solve them.

The CE60H3 angle roll from Ercolina increases the distance between lower shafts and interaxes to accommodate a wider range of profiles and increases roll shaft rigidity and radii accuracy with individual tie bar supports for each shaft.

New England’s premier manufacturing exposition returns May 16-18 to the Eastern States Exhibition in West Springfield, MA. Here are some technical reviews of the metal forming and fabrication equipment and systems that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Here are some of the latest advances in press operations that can help shops increase their productivity, improve quality and safety, and reduce their operating costs.

New applications from Global Shop Solutions help shops to simplify time and attendance and routine inventory processes.

Sometimes it’s equally as important to know what not to do as it is to know what to do. When it comes to investing in roll forming equipment and accessories, quality roll tooling designers must consider the possibilities for each customer.

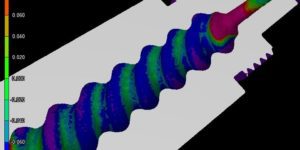

Direct metal deposition (DMD) with a coaxial powder nozzle can feed metal powder into a laser beam onto an existing three-dimensional surface to enhance surfaces, modify shapes, and restore damaged forming, punching, and injection molding tools and dies to like-new condition.

Understanding the specific alloy and how it will interact with different finishing processes can help guide you to choose the best finishing method for your application. Here are four key factors to keep in mind when finishing stainless steel.

The agenda is being set and manufacturers have an opportunity to get the issues that matter to them on the table. Now is the time to consider how NAFTA benefits or harms your business. Analyze what might happen if those benefits or burdens are changed or eliminated, monitor developments and participate in the process. To get started, here are some of the significant issues likely to be on the agenda, and some ways to ensure that your business’ interests are represented at the negotiating table.

New England’s premier manufacturing exposition returns May 16-18 to the Eastern States Exhibition in West Springfield, MA. Here are some technical reviews of the metal cutting equipment and systems that will be exhibited to help you navigate the show floor and manage your time while you’re there.

New England’s premier manufacturing exposition returns May 16-18 to the Eastern States Exhibition in West Springfield, MA. Here are some more technical reviews of the metal cutting equipment and systems that will be exhibited to help you navigate the show floor and manage your time while you’re there.

New England’s premier manufacturing exposition returns May 16-18 to the Eastern States Exhibition in West Springfield, MA. Here are some more technical reviews of the metal cutting equipment and systems that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Targeted at various welding industries, this new 52-page catalog from Dynabrade features a diverse line of air tools, abrasives and accessories for all types of grinding, blending and finishing needs.

New applications from Global Shop Solutions help shops to simplify time and attendance and routine inventory processes.

The agenda is being set and manufacturers have an opportunity to get the issues that matter to them on the table. Now is the time to consider how NAFTA benefits or harms your business. Analyze what might happen if those benefits or burdens are changed or eliminated, monitor developments and participate in the process. To get started, here are some of the significant issues likely to be on the agenda, and some ways to ensure that your business’ interests are represented at the negotiating table.

Using the RC-17 Fly-By-Wire Welding process from Weld Mold, operators can perform totally remote floodwelding from the safety of a temperature-controlled environment while maintaining total control of the welding operation and best welding procedures.

Take a closer look at some of these innovations in welding operations that can help fabricators increase their productivity, improve quality and safety, and reduce their operating costs.

Gun overheating can be a symptom of numerous problems, and it can result in catastrophic failure if ignored. Here are some common signs and causes of MIG gun overheating to be aware of that can help you prevent or quickly remedy the problem.

Knowing how to utilize the increased flexibility gained through laser welding can enable a fabrication shop to tackle tough challenges and creatively solve them.

Shops can now create a welding lab experience without a lab by using new technology that simulates various welding processes and blends real-world and computer-generated images into an augmented reality environment for a realistic welding simulation that closely resembles live arc welding – and provides them with an objective means of measuring the skills of each applicant.

New England’s premier manufacturing exposition returns May 16-18 to the Eastern States Exhibition in West Springfield, MA. Here are some technical reviews of the maintenance systems, tools and accessories that will be exhibited to help you navigate the show floor and manage your time while you’re there.

How can a shop reduce their operating costs when they face the challenges of machining difficult-to-cut metals and temperature-resistant super alloys, improving employee safety, and being more environmentally friendly? One solution lies in proteins . . . yes, that’s right, proteins.

The Safety LiftLok System

for vertical reciprocating conveyors from Wildeck includes passcode-protected digital keypad or key switch options to prevent lift operation by unauthorized personnel.

Starrett not only provides mechanics and technicians on the racing circuit with high precision tools, they also support the NASCAR Whelen Modified Tour.

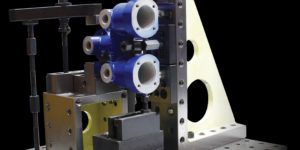

New England’s premier manufacturing exposition returns May 16-18 to the Eastern States Exhibition in West Springfield, MA. Here are some technical reviews of the tooling and workholding systems and accessories that will be exhibited to help you navigate the show floor and manage your time while you’re there.

New England’s premier manufacturing exposition returns May 16-18 to the Eastern States Exhibition in West Springfield, MA. Here are some more technical reviews of the tooling and workholding systems and accessories that will be exhibited to help you navigate the show floor and manage your time while you’re there.

New England’s premier manufacturing exposition returns May 16-18 to the Eastern States Exhibition in West Springfield, MA. Here are some more technical reviews of the tooling and workholding systems and accessories that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Targeted at various welding industries, this new 52-page catalog from Dynabrade features a diverse line of air tools, abrasives and accessories for all types of grinding, blending and finishing needs.

Think zero-point clamping workholding systems are only applicable to machining processes like milling? Think again. Because these systems can solve two of a shop’s toughest problems – repeatability of location from one fixture or workpiece blank to another, and quick transfer of work from one work area of the floor to another – the savings in setup time plus increased accuracy adds up quickly in a variety of operations.

Here are some ways to avoid six pitfalls that shops must keep in mind when considering a switch from manual deburring to automated brush deburring.

Starrett not only provides mechanics and technicians on the racing circuit with high precision tools, they also support the NASCAR Whelen Modified Tour.

New England’s premier manufacturing exposition returns May 16-18 to the Eastern States Exhibition in West Springfield, MA. Here are some technical reviews of the gaging, measuring instruments and inspection systems that will be exhibited to help you navigate the show floor and manage your time while you’re there.

This technology can inspect the interior structure of injection molded, cast, forged or fabricated parts made from metal, plastic, polymers, composites and 3D printed products, without causing any harm or destruction to the objects themselves. And that’s only the beginning.