May 2020

Digital Issue

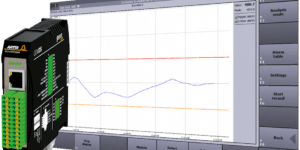

Convenience: The New Manufacturing Service. Machine failures delay orders, scrap parts, and cause costly downtime. Traditional service calls require expensive, time-consuming on-site visits by the equipment maker's technicians. Enter remote monitoring, an Internet of Things (IoT)-enabled post-sale service that can predict and prevent breakdowns. Machines collect and transmit operational data to the equipment maker via the cloud, where technicians can see, understand, and quickly troubleshoot the customer's equipment issue in near real-time.

Subscribe View Digital IssueTracking equipment purchases, labor hours, filler metal, and consumables is obvious and relatively straightforward. If you’re like many fabricators, though, you’re probably also budgeting for expenses you shouldn’t have to incur.

Metal-cored wire isn’t new, but there are often misconceptions about applications, cost, performance, strength, and workability compared to solid wire. Read on to learn how you might be missing opportunities to increase welding operation productivity for less cost.

Identifying the culprit can be complicated. Luckily, premature consumables failure, burnbacks, and bird-nesting are often easily resolved – so you’ll soon be welding again.

A global automotive wheels manufacturer worked with two industrial Internet of Things (IIoT) companies — IoTco LLC and Predictronics Corp. – to design and deploy a data-monitoring application that pinpoints potential future failures.

Manufacturer signs three-year service agreement that will transition the operation from fixing one robot at a time after a failure to monitoring the performance of 30 robots individually and as a fleet.

An estimated 10% to 20% of tools are changed out too soon to avoid failure during cutting. Edge computing is giving machine tool builders and manufacturers the tool they need to avoid such unnecessary expense.

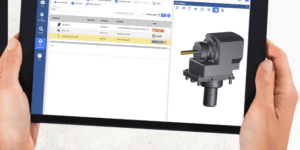

Trumpf makes remote support easier with an app and hardware that enables customers to more easily explain machine and software issues they’re encountering. The Smart Glasses enable the two parties to share and annotate photos and videos.

Tailored for the company’s M8, M7, and M6 Control Series, the CNC Total Care Package combines software backup, machine tuning, and preventive maintenance to minimize downtime. The goal is to make customers’ machines as productive as they were when new.

MachiningCloud fast-tracks a shop’s entire workflow by providing direct access to tooling data and speed-and-feed recommendations that can be read directly into CAM and simulation programs. In addition to enabling users to quickly configure the right tool for a job, the platform provides pricing and availability.

Standard on all new models of lasers, press brakes, and punch presses, LVD Strippit’s Teleservice is an Internet of Things (IoT)-enabled post-sale service that maximizes uptime by minimizing troubleshooting time. It’s also used to install control software and CADMAN software module updates.

Available in just one configuration, Trumpf’s TruBend 2100 is aimed at fabricators that don’t have enough volume to justify a high-end bending machine. Order the machine online directly from the company for $95,000.

Touted as the “E-standard of the future” for heavy-duty hydraulic press brakes, SafanDarley’s H-Brakes hydraulic press brakes range from 175 tons to 1250 tons in capacity and provide bending lengths from 3,100 mm to 6,220 mm.

MC Machinery Systems and Portuguese manufacturer Adira have formed a sales-and-service partnership to deliver press brakes with capacities ranging from 100 tons to more than 2,000 tons throughout North America.

With its 25-inch bending length and 30-inch table length, MC Machinery Systems’ 28-ton BB306 press brake fits just about any facility. AC servomotor and ball screw drive ensure high-speed productivity and repeatability.

LVD Strippit expands its Dyna-Press Series with the 40/15 Pro. The 40-ton press brake can be combined with an industrial robot to create an automatic Dyna-Cell bending cell.

Bystronic’s Xpert 40 press brake lets users automatically process large lots or manually bend small lots and individual parts. With a few simple steps, the Mobile Bending Cell’s robot aligns itself with the machine.

Bystronic’s Xpert 150-ton-to-320-ton press brakes automatically swap tools using a space-saving integrated tool changer. Users won’t bend a part using the wrong tool and tools aren’t incorrectly inserted into the machine’s upper or lower beam.

Available in three models with capacities ranging from 110 tons to 350 tons and numerous options, Bystronic’s Xpert Pro press brake offers a solution for virtually any sheet metal processing application.

Improvements in finishing tools over the last decade have opened the door to productivity-enhancing automation. Here are solutions manufacturers can confidently implement today.

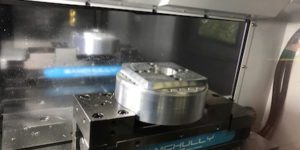

Featuring the newest CNC in Mazak’s Smooth Technology platform, the Variaxis C-600 simultaneous 5-axis VMC can optimize cutting via functions ranging from digital synchronization to artificial intelligence-powered machining modules. Optional robot interface enables automatic loading/unloading of parts.

Manufacturer signs three-year service agreement that will transition the operation from fixing one robot at a time after a failure to monitoring the performance of 30 robots individually and as a fleet.

In line with Industry 4.0, the rConnect central communications platform from GF Machining Solutions is one step closer to elimination of process downtime, improved machine performance, and fully predictive manufacturing process and product quality.

Tailored for the company’s M8, M7, and M6 Control Series, the CNC Total Care Package combines software backup, machine tuning, and preventive maintenance to minimize downtime. The goal is to make customers’ machines as productive as they were when new.

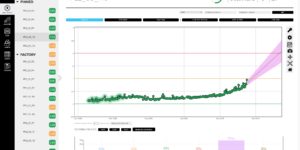

Predictive analytics diagnose pre-failure conditions before downtime occurs. Mazak’s Spindle Health Monitoring System uses edge computing and algorithms to model a spindle’s baseline signature against which anomalies that indicate developing alignment or balance issues are readily identifiable.

MachiningCloud fast-tracks a shop’s entire workflow by providing direct access to tooling data and speed-and-feed recommendations that can be read directly into CAM and simulation programs. In addition to enabling users to quickly configure the right tool for a job, the platform provides pricing and availability.

Hoffman Group’s Garant Xtric is available with a center jaw, gripper mounting holes, endutec automation interface, and four additional base lengths. The vice provides 25 kN of clamping force.

Palmgren’s 8.5-inch-by-27-inch vertical machining center (VMC) is an economical way to manufacture small parts. An automatic tool changer and 8-tool magazine make the machine suited for prototyping and short run shops.

Methods Machine Tools is offering four 3-axis vertical machining centers (VMCs) and a 5-axis bridge-type machining center made by Taiwanese tool builder Litz Hitech. Equipped with Fanuc controls, they provide an accurate and reliable mid-range machining solution.

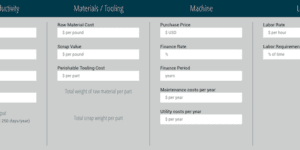

Find out using a free machine tool payback calculator created by the Copper Development Association Inc. (CDA). Visit https://highspeedmachiningbrass.com/profit/.

Designed for large-volume production of complex structural components for the automotive and aerospace industries, the FZ/DZ 25 series of two-spindle vertical machining centers (VMCs) from Chiron Group delivers 20,000 rpm in a small footprint.

The Tongtai VTX series from Absolute Machine Tools provide speeds up to 2,362 ipm in all axes and acceleration of 1.2 g. Two types of high-speed automatic tool-changing systems are available.

The Xpress press brake offers a competitive edge thanks to Bystronic technology.

Manufacturer signs three-year service agreement that will transition the operation from fixing one robot at a time after a failure to monitoring the performance of 30 robots individually and as a fleet.

Fabricators tend to operate by anecdotal evidence and company history. Data-management tools like ESAB’s Digital Solutions can help companies understand — and move the needle on — their true drivers of productivity.

Tracking equipment purchases, labor hours, filler metal, and consumables is obvious and relatively straightforward. If you’re like many fabricators, though, you’re probably also budgeting for expenses you shouldn’t have to incur.

Metal-cored wire isn’t new, but there are often misconceptions about applications, cost, performance, strength, and workability compared to solid wire. Read on to learn how you might be missing opportunities to increase welding operation productivity for less cost.

Mazak expands its line of multitasking machining centers with the VTC-300C FSW, a milling machine with friction stir welding (FSW) package for joining alloys with low melting points. Machine also features full traveling-column design, automatic tool changer, and 40-taper spindle.

Comprised of three scientifically balanced oxides that promote migration and evaporation rates, Diamond Ground Products’ thorium-free Tri-Mix tungsten electrodes are a cost-effective and safe alternative to Wolfram Industries’ 2% thoriated tungsten electrodes.

When used with the company’s PV-2 spark-arresting vent, the YZ102 from Best Purging Systems expedites purging by supplying, regulating, and monitoring gas supply to an enclosure. Available in three mounting positions.

The biggest challenge to achieving a strong bond when welding thick walls are discrepancies between the CAD drawing and the in-process weld. Pemamek’s laser scan-driven control system overcomes this difficulty by automatically correcting weld path based on groove geometry.

Identifying the culprit can be complicated. Luckily, premature consumables failure, burnbacks, and bird-nesting are often easily resolved – so you’ll soon be welding again.

Improvements in finishing tools over the last decade have opened the door to productivity-enhancing automation. Here are solutions manufacturers can confidently implement today.

Predictive analytics diagnose pre-failure conditions before downtime occurs. Mazak’s Spindle Health Monitoring System uses edge computing and algorithms to model a spindle’s baseline signature against which anomalies that indicate developing alignment or balance issues are readily identifiable.

A global automotive wheels manufacturer worked with two industrial Internet of Things (IIoT) companies — IoTco LLC and Predictronics Corp. – to design and deploy a data-monitoring application that pinpoints potential future failures.

Unlike boring tools that involve time-consuming benchwork and complicated measuring for proper part repositioning, Seco Tool’s JC898 rougher and JC899 hybrid stacker simplify CFRP-titanium and CFRP-aluminum hybrid material holemaking and milling operations by eliminating post-machining work.

Samchully power vises feature a mechanical multiplier booster system to provide high force with minimal input at the handle. Set the clamping force with the one-touch preset dial and the key stops turning when desired torque is reached.

Rohm’s Easylock system offers repeatability of less than 5 µm. Its draw bolt system creates a precision interface between the receiver unit and pallet carrier, which can be fitted with vises, stationary lathe chucks, collet chucks and customized fixturing solutions.

Kennametal’s chip-friendly fluke design keeps stainless steel, nickel, and cobalt-based alloys from sticking to the cutting tool in aerospace and energy applications. The B21*SGL’s low thrust level enables productive drilling in delicate workpiece geometries.

A sensor on JW Winco’s GN 817.6 indexing plunger reports visual and audible alerts when the plunger pin passes two-thirds of the plunger distance. A three-wire electrical signal is transmitted by cable, which integrates more easily than a wireless connection.

Offering flexibility and cost savings, the Preci-Flex modular toolholding system from Exsys Canada enables shops to capitalize on the ER collet pocket concept. Compact design enables maximum torque transmission for better machining accuracy.

Hoffman Group’s Garant Xtric is available with a center jaw, gripper mounting holes, endutec automation interface, and four additional base lengths. The vice provides 25 kN of clamping force.

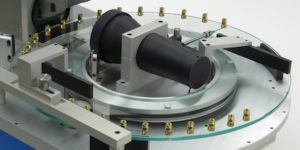

Parallelism of the axis of rotation and accuracy of its center are fundamental characteristics for a machine tool with rotary axes to properly function. AxiCheck software from Marposs enables users to quickly correct errors that could impact the workpiece and conduct proactive maintenance.

The TS8996 RSE from Rohde & Schwarz uses the company’s Elektra EMC test software, which has been upgraded with measurement and calibration routines for 5G development and compliance tests. The system enables fully automatic emission measurements on wireless communication equipment.

With four monitoring modules, the Artis GEMDS system from Marposs provides real-time feedback on spindle characteristics that’s critical to avoiding out-of-tolerance parts. The system easily integrates into existing controls, network environments, and Industry 4.0 solutions.

Monitoring drawbar force is fast and easy with JM Performance Products’ ClampForce gage. With gage heads available in four ft/lb configurations, the gage is sold as a complete kit in a heavy-duty toolbox.

The Heidenhain ERM 2203 is ideal for contaminated environments and applications that don’t require an optical encoder’s accuracy level. The magnetic ring encoder retains the 200 µm signal period, but with approximately 30% less graduation error.

Exact Metrology is distributing the German-made GOM CT scanner in the U.S. In addition to controlling the device, the scanner’s software analyzes and provides high-resolution internal as well as external component geometries in 3D.

Big Kaiser’s entry-level Speroni STP Essentia tool presetting system is efficient and easy to use. Operators measure and match cutting edges of tools to the job right next to the machine tool.

American Precision Gauge solves an age-old measuring limitation for shafting, piping, tubing, and other long components. Use the digital caliper for quality control or build it in as a setup gauge or touch-off.

A Michigan automotive component supplier finds the ideal tool for quickly and confidently ensuring 600 active parts meet zero-defects requirements. Two Resec Systems ShadowGage Sorters paid for themselves within six months.