May 2021

Digital Issue

The New Chemistry of Clean: Over the next two to five years, the Environmental Protection Agency (EPA) will phase out or regulate 10 common solvents. Read this issue for more information on chemicals and/or processes to meet customer specifications and governnment requirements.

Subscribe View Digital IssueCollaborative-style robots combined with mobile robots are increasing shop capability and interacting more freely with their human coworkers.

Uncertainty is subsiding as the pandemic recedes, heralding business revival.

Solutions are automatically navigating through the shop floor to tend machines and perform tasks alongside human coworkers.

Uncertainty is subsiding as the pandemic recedes, heralding business revival.

Collaborative-style robots combined with mobile robots are increasing shop capability and interacting more freely with their human coworkers.

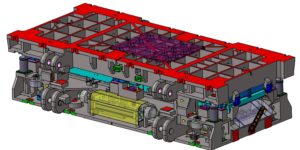

Tooling Tech Group can analyze incoming part files, fix clash and clearance violations, identify tool design changes, and make adjustments to achieve the highest strokes per minute (SPM) without going through trial and error on the stamping floor. This applies to servo, mechanical and hydraulic presses regardless of manufacturer.

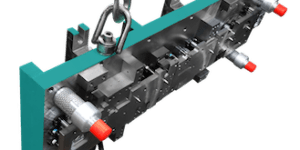

Throw out your rubber bands and twist-wire! Superior Die Set’s Cage Saver retracts ball bearing retainer cages during die-handling and maintenance and protects the assembly from water and detergent during pressure washing.

Murata Machinery’s Motorum M2044TS turret punch press uses a servo-electric punch drive system that incorporates the latest ram drive design. Large turret provides more stations for greater flexibility and increased productivity, and its smaller table is sized to accommodate limited floor space.

LVD’s Strippit PL provides a fiber laser cutter and punch press in one machine. The combination enhances efficiency by reducing production time and material handling, and lowers cost per part in both small lot sizes and high-volume runs.

Powered by a servo drive instead of a flywheel, Karl Klink’s RT-HLKK1000 ball cage punching machine improves cut quality by increasing cutting speed. Two die stations and streamlined retooling process also help shorten cycle times from 10 to 7 seconds.

Offering 22 and 30 tons of force, the Q5 CNC is the largest of Haco’s three turret punching machines. Automatic tool changer that rotates at a speed of 122 milliseconds eliminates wear common to traditional turret punching machines.

Fabricators can easily integrate Boschert’s Compact EVO CNC punching machine into their networks via the machine’s interface. Operators can program complex CAD parts with the company’s BG Cut software.

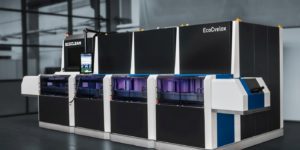

Combining high-pressure water jet deburring with low-pressure part cleaning and drying processes, the EcoCvelox from Ecoclean Inc. is a one-stop finishing solution. Highly configurable equipment enables highly flexible process design.

Multicyl’s Press in a Box and MultiPunch Linear Rail work together to add versatility to tooling applications and press solutions.

Houghto-Prep ZP5 phosphorus-free cleaner and self-limiting coating from Quaker Houghton is for ferrous, aluminum, and other non-ferrous components in preparation for paint and other organic coatings.

Specialized furnaces with integrated hydraulic press systems use superior control of pressure and temperature to create better diffusion bonds when joining similar or dissimilar metals for fuselages, actuator fittings, landing gear trunnions, nacelle frames, nuclear control rods, turbine blades, medical devices, heat exchangers, lithium batteries and more.

Does limited punching capacity and outsourcing lead times cause production delays in your shop? Here is a simple, affordable and effective system that can expand the capabilities of your press brakes, help streamline operations and eliminate the need for outsourcing or purchasing new equipment.

The two-cylinder/two-person operation of the MM Series Complete Five-Station Fabrication Center from Kalamazoo Metal Muncher allows the punch and shear end to be operated separately, independently and simultaneously at full capacity and speed. Their GB Series Hydraulic Punch Press can also be fitted with special tooling to allow shearing or forming.

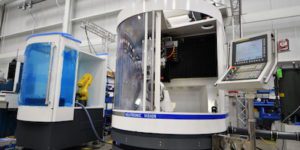

Vollmer’s 5-axis VGrind 340S machines carbide drills and milling cutters with diameters from 0.3 mm to 12.7 mm, sizes increasingly in demand in the automotive, electronics and medical sectors. Automation options enable unattended production around the clock.

Owners who rebuild their Walter Helitronic Power machine can get the same speed, functionality, and ease of use as new models without the expense of buying a new machine with standard automation features.

United Grinding’s Studer S41 (universal) and S131R (radius internal) are designed to produce large, heavy canning and die-forming components from the extremely hard metals commonly used in the packaging industry.

Star Cutter’s NXT runs the latest NUM tool-grinding software, provides automated marking, accommodates denser pallet arrays, and produces multiple profiles for tools up to 10 inches in diameter in a single run.

Palmgren claims its line of heavy-duty bench grinders provides four to seven times longer duty cycle under load and eight times less speed degradation than competing products. Wheel diameters: 6 to 12 inches.

Automatic phase, notch-position and effective-diameter adjusters along with automatic wheel in-feed position adjustment ensure Mitsui Seiki’s GSH 200A thread grinder delivers consistently repeatable precision.

Featuring a longitudinal feed rate of 975 inches/minute and vertical feed of 17 inches/minute, Kaast’s F-Grind AH Series is equally capable of achieving a high-quality surface finish or critical dimensions on cutting and threading tools, punches and gauges.

Glebar’s PG-9DHD centerless form grinder accepts a 10-inch-wide work wheel to produce multiple parts per cycle in a single infeed motion. It shapes spherical and cylindrical components 0.050 to 4 inches in diameter.

Both a grinding and a turning machine, EMAG’s VLC 350 GT speeds transmission component production by enabling multiple machining processes of chucked parts in a single clamping operation.

Get more life out of virtually any brand of tooling for turret presses, ironworkers, and rooftop punches as well as progressive and other dies with DCM Tech’s turnkey punch and die grinder (PDG) with 18-inch rotary table.

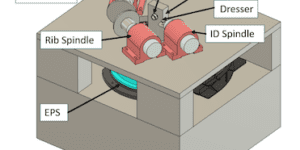

Almost any operation that requires a combination of high accuracy and high force can be improved with the Eccentric Positioning System (EPS) from Coventry Associates. The grinder uses three circular rotary tables on top of each other instead of linear slide systems.

United Grinding’s Blohm Profimat XT relies on a 80 hp spindle and 20-inch-diameter grinding wheels to fashion workpieces weighing almost 1,800 pounds. Control interface customized to visualize machine monitoring data.

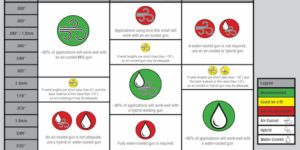

Many shops hesitate to incorporate abrasive finishing tools in CNC machines for fear of clogging coolant lines and damaging slides and bearings. However, finishing tools generate very little grit.

Weld Systems Integrators’ next generation of capacitive discharge (CD) welders monitors force in real time to ensure consistent-quality results. Throat depth provides room for automation options such as end effectors and fastener feeders.

Taylor-Winfield Technologies’ linear friction welders use solid-state bond welding to join parts of the same or different material in various geometries. Operators can adjust frequency and amplitude during the process.

Georgia-based Standard Resistance Welder products include Models RS1 and RS2. Offering a wide range of standard and optional features, the heavy-duty rocker arm seam welders are built around welded steel bases.

Financing, lease, rental, and recondition-to-new programs are available for all Seedorff ACME rocker arm, pedestal, bench, press-type, seam, butt-and-tee and multispot resistance welders. Automation options available.

The actuator’s dual linear bearings and a digital load cell enable Emerson Industrial Automation’s Branson GMX-20MA ultrasonic spot welder to deliver consistent quality from weld to weld by maintaining energy levels.

Solid state and resistance welding use pressure and/or electric current to fuse dissimilar metals, nonferrous metals, and composites without generating defects, like gas porosity and hot cracking, seen in fusion welding. Think things like bus bars and switches in automotive electric systems and appliances and nuts and fittings on various parts.

Proper cable and consumables selection and tool center point (TCP) control play go a long way toward improving quality and optimizing overall equipment effectiveness (OEE). Establish a thorough pre-implementation plan and monitor key issues to get the most of your investment.

Mazak expands its line of multitasking machining centers with the VTC-300C FSW, a milling machine with friction stir welding (FSW) package for joining alloys with low melting points. Machine also features full traveling-column design, automatic tool changer, and 40-taper spindle.

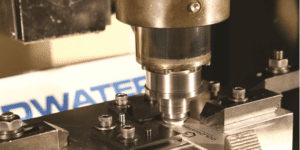

The automated SpinMeld friction spin welding system from Coldwater Machine is a very fast solid-state joining technology for steels, aluminum, cast or sintered metals, carbide materials, magnesium, nickel, molybdenum, and other exotic materials that normally may not be welded using other methods.

Owners who rebuild their Walter Helitronic Power machine can get the same speed, functionality, and ease of use as new models without the expense of buying a new machine with standard automation features.

Viking Blast & Wash Systems adds the model 48T shot blaster to its industrial line of table blasters. Airless blast cleaning is accomplished via one 15-horsepower VMax center-fed blast wheel.

Safechem’s Dualene 1601 S is the first pre-stabilized, pure and virgin-grade modified alcohol developed for a wide range of metal cleaning applications. Results are comparable to Dow Chemical’s Dowclene 1601.

Kyzen’s Metalnox M6314CP cleaner and corrosion inhibitor can be used in virtually any industrial cleaning system and process to remove manufacturing oils from machined and fabricated parts.

MAFAC machines from Jayco Cleaning Technologies can be programmed to rotate the basket with or against the spraying frame. Built-in oil separators and demisters eliminate the need for an external device and exhaust ducting.

Gosiger’s Kleen Power (KP) KP.HMA machines remove contaminants from hard-to-reach, small-diameter tapped holes, blind holes and deep counter bores. The energy-efficient vacuum washers increase productivity by continually separating, cleaning, and reusing solvent.

In multiple industry and OEM tests, Daubert Cromwell’s ClearPak 5000 earned the highest rating as a vapor corrosion inhibitor (VCI) for protecting aluminum, steel, and copper parts during storage and shipping.

Available as a bag or film, Cortec’s EcoSonic VpCI-125 guards against corrosion as well as damage from electrostatic discharge (ESD). Bonus: The vapor phase corrosion inhibitor (VpCI) product is recyclable.

By providing full immersion as well as spray cleaning, Ransohoff’s LeanDrum CF for high-volume cleaning and cold forming applications eliminates the heat loss common in traditional spray systems and lowers chemical consumption.

BHC’s one-product AquaVantage 3800 GD doesn’t contain any regulated ingredients. The mild formulation is safe and effective for cleaning steel, aluminum, and titanium parts for a wide range of manufacturing sectors.

Solvent-based vacuum degreasing is good for the environment, employees, and the bottom line. One machine cleans and dries parts by “sucking out” any remaining vapors before an operator touches them. Many systems also filter lubricant for reuse.

Madison Chemical’s phosphate-free Aluma-Cling Blue eliminates having to brush by hand to clean bright aluminum and stainless steel. Clean-Gard 83 is an alkaline detergent that produces low-to-moderate foam, making it ideal for cleaning via ultrasonic cavitation.

Houghto-Prep ZP5 phosphorus-free cleaner and self-limiting coating from Quaker Houghton is for ferrous, aluminum, and other non-ferrous components in preparation for paint and other organic coatings.

Here are some innovative industrial parts washing systems that effectively eliminate the manual aspect of cleaning so that your shop can reduce costs and increase profit.

Early adoption of JM Performance Products’ High Torque retention knobs helped a titanium machining company overcome deficiencies at the spindle to advance its aerospace production trajectory.

Seco Tools’ Turbo 16 square shoulder cutter inserts are the company’s first products with data matrix tags. The scannable codes store product and batch information, and can be read by the Seco Assistant smartphone app.

Four-edged inserts help Sandvik Coromant’s CoroMill 415 face milling cutter reduce cost per component and increase productivity via a high metal removal rate. An E-M30 geometry complements M-M30 geometry assortment.

Two tips on Lach Diamond’s CBN-Duo-power inserts are finished with type B610 or type B600 cubic boron nitride (CBN) to increase productivity when turning automotive components out of materials such as case-hardened steels and powder-metal alloys.

Kennametal is leveraging its experience with polycrystalline diamond (PCD) tooling for the automotive industry to provide cost-competitive and highly productive drills, reamers, and end mills for aluminum machining.

Featuring square double-sided inserts with eight cutting edges, Iscar’s Neodo family of 90-degree indexable milling cutters enables face and shoulder milling in steel and cast iron as well as milling close to shoulders where there are workpiece or workholding fixture constraints.

The Hoffmann Group’s Garant Master Tap INOX taps are available in inch sizes as well as metric threads with a longer design for increased reach and for all thread standards.

The phase-hardened ceramic substrate on Greenleaf’s XSYTIN-360 end mills provides ultra-high strength and wear resistance at twice the feed rate of carbide end mills when slotting, pocketing, and profiling high-temperature alloys and other difficult-to-machine materials.

A Tier 2 automotive supplier wasn’t getting the most possible out of its vertical machining center until the shop tooled up with the TOP-Cut VAR end mill and FPC milling/drilling chuck from Emuge.

Featuring the greatest number of cutting edges available for positive inserts, Dormer Pramet’s S450E double-positive 45-degree milling cutter allows the same cutter body to be used with octagonal inserts for face milling and round inserts for face/copy milling.

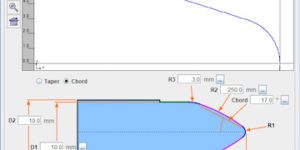

In addition to a user-friendly design wizard, ANCA’s ToolRoom enables cutting tool manufacturers to expand into new markets with barrel shape ballnose (BSB) and large-radii double corner radius (DCR) endmill tool types that increase productivity.

Throw out your rubber bands and twist-wire! Superior Die Set’s Cage Saver retracts ball bearing retainer cages during die-handling and maintenance and protects the assembly from water and detergent during pressure washing.

Powered by a servo drive instead of a flywheel, Karl Klink’s RT-HLKK1000 ball cage punching machine improves cut quality by increasing cutting speed. Two die stations and streamlined retooling process also help shorten cycle times from 10 to 7 seconds.

Many shops hesitate to incorporate abrasive finishing tools in CNC machines for fear of clogging coolant lines and damaging slides and bearings. However, finishing tools generate very little grit.

Multicyl’s Press in a Box and MultiPunch Linear Rail work together to add versatility to tooling applications and press solutions.

Jarvis Cutting Tools works directly with machine builders to develop exclusive high-performance taps that address current and future production requirements.

One simple, high-cycle punch and die operation automatically feeds, punches, inserts and locks the self-piercing FAS-NER from AKH to produce a solid joint in similar or dissimilar metals and thicknesses.

Does limited punching capacity and outsourcing lead times cause production delays in your shop? Here is a simple, affordable and effective system that can expand the capabilities of your press brakes, help streamline operations and eliminate the need for outsourcing or purchasing new equipment.

Renishaw’s multisensor REVO 5-axis measurement system provides highly accurate scanning, non-contact inspection and surface finish analysis at ultra-high speeds on one coordinate measuring machine (CMM).

The LEXT OLS5100 laser microscope from Olympus guarantees measurement accuracy that simplify experiment workflows. The software’s several smart features minimize error with push-button scanning and analysis.

Optical Gauging Products’ multisensor TeleStar Plus laser measures a wide range of materials and surface textures with extremely high accuracy. Its through-the-lens (TTL) design eliminates offset between the optical and laser sensors.

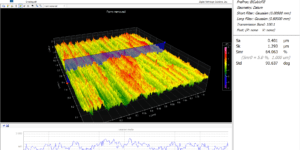

OmniSurf3D from Digital Metrology Solutions helps users understand and communicate about surface texture without requiring a great deal of mathematical interpretation or metrology knowledge. The software provides the ability to interact with data from virtually any surface measurement instrument.

Automated Precision’s portable vProbe performs CMM-style measurements on the shop floor and is more versatile than a portable-arm coordinate measuring machine (CMM).

Many shops hesitate to incorporate abrasive finishing tools in CNC machines for fear of clogging coolant lines and damaging slides and bearings. However, finishing tools generate very little grit.

Combining dimensional metrology and surface roughness measurement, the InfiniteFocus G5 from Bruker Alicona provides high repeatability and vertical resolution of up to 10 nanometers. An interface equips the system for fully automatic measurement during production.

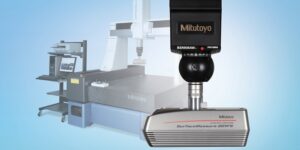

The Flying Spot SurfaceMeasure 201FS laser sensor from Mitutoyo uses a point scanning method to achieve high reproducibility, best-in-class scanning accuracy and a high data acquisition rate for inspection and reverse engineering of small components.

The Hommel-Etamic Toposcan system from Jenoptik can automatically measure the size of porosity and blow holes, stroke reversal radius, laser pocket structures, roughness of bore walls, torn and folded metal and cross-hatch angles.

The SR160 Surface Roughness Tester from Starrett is tough, shock tested, and capable of withstanding the demands of a shop environment.