May 2023

Digital Issue

Embrace Disruption: The Supply Chain. Being able to respond to customers' needs in a timely manner is essential — and the ability to respond logistically continues to be challenged. Enhanced supply chain management practices enable your shop to meet a variety of goals. We review logistics considerations metalworkers should be concerned with and ways to mitigate any challenges. Enterprise Resource Planning (ERP) systems are one method of addressing your shop's unique needs. We also learn how reshoring and nearshoring of manufacturing and supply operations is impacting the flow of goods.

Subscribe View Digital IssueMake certain your products are marked with devices and systems that ensure reliable and dependable part traceability.

New and exceptional workholding products assist you in navigating the road to success.

Steady wire feeding promotes better weld quality. New equipment protects wire integrity.

The supply chain is forging stronger links, driven by trends in ERP systems, digitalization, as well as newfound opportunities thanks to reshoring and nearshoring initiatives.

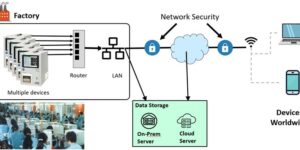

Ensure people, process and culture are part of your technology initiatives.

The supply chain remains affected by the challenges ushered in with the global pandemic. Take steps to triumph over delays and hold ups.

Make certain your products are marked with devices and systems that ensure reliable and dependable part traceability.

Variations in machinery allow users to create unique designs and applications to support the emerging small tube segment.

How tolerances are used in tube bending and why they matter.

Stocked with metal fabrication machines ranging from entry level to custom designed, and full parts and service departments, Trilogy Machinery collaborates with customers to determine the best solutions for their applications.

The throughput gains offered can be intoxicating. But is it for everyone?

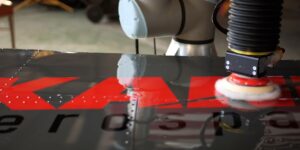

Workers at an aerospace company were attracted to cobots primarily because of the unique collaborative element that enables humans and robots to work together.

Make certain your products are marked with devices and systems that ensure reliable and dependable part traceability.

Workers at an aerospace company were attracted to cobots primarily because of the unique collaborative element that enables humans and robots to work together.

Get the most from your robotic welding investment through careful planning and continued monitoring.

Laser systems remove residue, corrosion, and existing coatings from metal weld surfaces quickly, with less preparation and mess than traditional techniques.

Artificial Intelligence (AI) and Machine Learning (ML) algorithms are widely used in our modern, digital society to monitor our habits, serve “appropriate” advertising, suggest which new television series to watch, and more. AI/ML is also being implemented, less visibly, in…

New and exceptional workholding products assist you in navigating the road to success.

Solid carbide drills support innovative manufacturing, and due to their higher metal efficiencies contribute to and maximize a shop’s productivity levels.