November-December 2014

Quantifying and adapting the “feel” of the abrasive against the part is a critical step toward successfully automating this labor intensive offhand operation.

Returning your machine or a program to its original condition can now be as simple as saying “big data.”

In considering which weld fume management solution is right for your shop environment, be aware that it may be necessary to implement multiple solutions from the agency’s outlines to achieve the desired exposure limits for each individual metal, metal oxide or gas found in the weld plume. Here are the steps to follow.

As part of the Ford College Alliance, qualified students will be awarded $10,000 in Ford Blue Oval Scholarships.

A yearend review of some of the current advances and application capabilities in each of these metal cutting technologies.

Evolving from a rough and cranky process to a reliable and productive technology, high-density plasma cutting has become a metal fabricating success story.

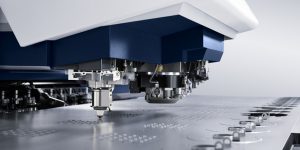

You may discover a whole new profit method in a combination processing machine that can produce all of the geometries you need at the same cost, regardless of the number of parts required.

The MILLHOG APS-438 Air Powered Saw and steel WrapTrack System from ESCO is a rigid pipe cutting system suited for cutting stainless steels, Inconel®, and other highly alloyed pipe without leaving a heat affected zone.

As part of the Ford College Alliance, qualified students will be awarded $10,000 in Ford Blue Oval Scholarships.

Take a look at how this automated machining cell from Makino gave Superior Machining & Fabrication the tools to grow their capacity and increase into volume production.

Take a look at how this gear specialist and machine shop used new Swiss grinding technology with an advanced CNC to cut their cycle time on one gear from 40 minutes down to six minutes.

Returning your machine or a program to its original condition can now be as simple as saying “big data.”

The SPRINT 20|5 from DMG MORI is ideal for the high volume production of simple to medium complexity parts machined from bar.

The flexible G7 Grinder 5-axis horizontal machining center from Makino grinds, drills and mills aerospace blades, vanes, turbine disks and other complex components.

Step-by-Step Improvements: Understanding the Value of Advanced Welding Information Management Systems

With VideoTo achieve big cost savings, quality improvements and productivity enhancements, advanced data management systems can manage and control almost any factor – before, during and after the actual welding process.

In considering which weld fume management solution is right for your shop environment, be aware that it may be necessary to implement multiple solutions from the agency’s outlines to achieve the desired exposure limits for each individual metal, metal oxide or gas found in the weld plume. Here are the steps to follow.

An advanced CNC retrofit package gives a new lease of life to hob sharpeners by doubling accuracy and immensely increases machine productivity.

Since retrofits, rebuilds or remanufactures typically cost between one-third to two-thirds the price of a new machine, many shops are choosing this route to improve their uptime and availability. Here are some re-cent examples.

Canyon Hydro sped up deliveries by two months – without raising machining costs – with a last minute processing switch and a new multipurpose mill that roughs out 4,500 lb of chips in one-third the time of conventional face mills.

This new modular interface for carbide cutting tool heads provides maximum stability, load capacity and high runout precision based on an innovative thread design with a proprietary double cone connection and an additional third supporting area in the back of the interface.

A twelve-tooth groove milling tool bites 19 hours off the 80-hour cycle time on a tough-to-machine part and keeps potentially outsourced work in-house – with greater profit.

Quantifying and adapting the “feel” of the abrasive against the part is a critical step toward successfully automating this labor intensive offhand operation.

Pneumatic 6-jaw front-end LVE chucks from Röhm are ideal for machining the ends of especially large and long pipes used for extracting crude oil or natural gas.

The Morse 811 portable band saw blade from M. K. Morse combines an aggressive tooth with a variable tooth pattern to reduce vibration and increase cutting speed.

Multicyl combines the standard Multicyl MC series, the HZ frame, and the HZ unit from Unipunch to punch angles, tube edges, and hard to reach extrusions.

The CoroMill 176 range of full profile hobs from Sandvik Cormant is ideal for roughing, semi-finishing and finishing operations on both hobbing machines and multi-task machines/five-axis machining centers.

The CoroDrill 870 from Sandvik Cormant makes holes more efficiently and closer to required specifications required so they are better equipped for subsequent operations.

The PWS Shoulder Milling Cutting Series from Sumitomo is an excellent roughing tool that takes heavy depths of cut and punishment in various materials and still provides excellent tool life.

CoroCut QD from Sandvik Coromant ensures predictable and consistent tool life for reproducible parts in high volume bar feeding applications.

With space in short supply on complex welding and assembly fixtures, the 8700 series pneumatic lever clamp from DE-STA-CO provides superior holding power for any type of tooling.

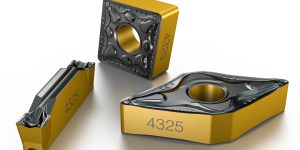

Grades GC4315 and GC4325 with Inveio from Sandvik Coromant are ideal for soft stage turning that comes before case hardening.

A review of some of the current advances and application capabilities in measurement and inspection technologies.