November/December 2021

Digital Issue

Can You See Me? Augmented Reality for Maintenance & Training. By utilizing augmented reality for maintenance and training, users wearing headsets can see both virtual and physical realities simultaneously. By creating a digital overlay of equipment, manufacturers can immediately troubleshoot issues with technicians and experts located offsite, versus waiting for a technician to arrive. Augmented reality is also ideal when it comes to workforce training. This method keeps everyone in place at the shop and not on the road traveling to offsite training spots. Find out how augmented reality can assist your shop with not only maintenance and training but also mentoring and product development, among other functions.

Subscribe View Digital IssueCapital is available to support your company’s preparedness projects. Discover ways you can plan for financial success, even if a weather disaster strikes, and move your organization forward.

Magnetic lifting systems and control valves allow operators to make efficient use of their time when handling steel, which typically can be difficult and time consuming to job shops.

Tube and pipe inspections can be conducted quickly, with accuracy, and with one-stop solutions.

Capital is available to support your company’s preparedness projects. Discover ways you can plan for financial success, even if a weather disaster strikes, and move your organization forward.

Press breaks, stamping presses and shears facilitate productivity increases and cost savings.

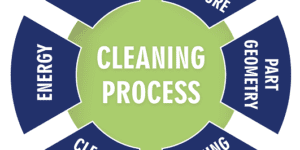

There are many choices when it comes to selecting cleaning processes and chemistries. Here are a few tips to assist in staying on top of changing technologies to meet your shop’s performance levels.

Avoid potential issues in additive manufacturing with high-performance materials such as Hastelloy X, which has become a material of choice due to its long-wear characteristics. Super alloys offer potential game-changing technology.

You will meet or exceed expectations by partnering with a press manufacturer that is an authorized systems integrator, and truly understands the scope of your goals by adding a fully integrated automation solution.

Rev up data transfer rates without impacting command of your procedures.

Digital data support allows your shop to pinpoint slowdowns in the production process because you can visualize the entire welding operation, down to individual weld parameters, for example.

The synergies vision guided robotics (VGR) bring to the shop floor are numerous. Learn about the types of VGR systems and the trending uses for robotic automation.

Following best practices and utilizing reliable, high-quality wire feeders and consumables will reduce issues and costs regarding wire feeding challenges.

By utilizing AR or VR, users with headsets or with smart glasses or smartphones can learn how to maintain machinery or troubleshoot pieces of machinery.

Fabricators can attain spotless and unsoiled parts and machinery in an environmentally responsible way.

Reduce machine downtime and improve efficiencies by using products designed to tackle the most demanding maintenance challenges.

Improvements to handheld tools and drills allow fabricators to work with more powerful and safer products to get the job done.

When grinding aluminum, aluminum oxide grain is the standard. Make the time to match the best bond for your application because the bond used in manufacturing an abrasive wheel has a remarkable impact on the wheel performance.

Toolholding considerations are often one of the last thoughts during a setup process, but the toolholder determines the success of how the cutting tool performs. When was the last time your shop reviewed your toolholders?

Tube and pipe inspections can be conducted quickly, with accuracy, and with one-stop solutions.

Laser weld inspection systems using 3D imaging can improve productivity and quality control of ERW and HFI tube welding by working in conjunction with other NDT testing.

The synergies vision guided robotics (VGR) bring to the shop floor are numerous. Learn about the types of VGR systems and the trending uses for robotic automation.

Dimensional measurement data provides operators with actionable decision making that first reduces, and then eventually eliminates defects.