November/December 2023

Digital Issue

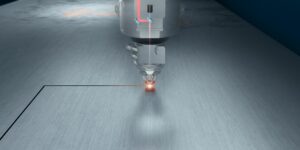

Redefining Laser Cutting: The future of laser cutting systems has arrived and the outlook is exciting. Fabricating & Metalworking asked leading suppliers of laser cutting equipment to share their insights and their responses provide a compelling and unique look into what's next for laser cutting. Advances include machine monitoring where lasers watch and listen to the process, with innovations that respond to material variations in real time. These systems also feature intuitive software that reduces scrap by maximizing nesting, as well as eco-friendly solutions to reduce energy use and emissions in the laser cutting process. High-speed automated cutting and sorting capabilities, robots and autonomous mobile vehicles further support your competitiveness and bottom line.

Subscribe View Digital IssueCollect data from all aspects of your abrasives operation to provide a full picture and uncover the solutions needed to deliver time and cost savings.

Robotic deburring and finishing solutions replace tedious manual processes, with precision.

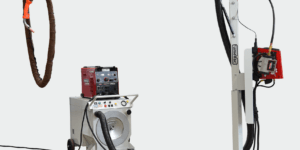

Greater weld fume extraction coupled with flexible and portable solutions improves working conditions and lowers the cost of extracting toxic weld fumes.

Collect data from all aspects of your abrasives operation to provide a full picture and uncover the solutions needed to deliver time and cost savings.

Robotic deburring and finishing solutions replace tedious manual processes, with precision.

The next generation of laser cutting systems require less operator intervention thanks to automation and robots, freeing up operators to do other tasks.

DoALL Sawing Products provides the industry’s most comprehensive inventory of metal-cutting products. With its long history of metal-cutting expertise, the company continues as a leader in band saw innovations.

Fewer blade changes, one stop approaches, and automatic feeds and saws maximize productivity with little operator involvement.

Panelists at Mazak Discover discussed job shops and the workforce: with automation you are not reducing labor but adapting the skill sets needed to thrive in the factory of the future.

Automated solutions and other advances on machining centers increase flexibility and productivity within your processes.

Panelists at Mazak Discover discussed job shops and the workforce: with automation you are not reducing labor but adapting the skill sets needed to thrive in the factory of the future.

Greater weld fume extraction coupled with flexible and portable solutions improves working conditions and lowers the cost of extracting toxic weld fumes.

Advanced technology joins dissimilar metal components on the same machine, resulting in high seam strength and capital savings.

Regardless of your skill level, using subpar equipment will put your work at risk or make it harder to optimize output.

Collect data from all aspects of your abrasives operation to provide a full picture and uncover the solutions needed to deliver time and cost savings.

Robotic deburring and finishing solutions replace tedious manual processes, with precision.

Enhancing machine utilization, reducing changeover time, and implementing modular systems all contribute to increasing the flexibility of machine shops.

Machine tool probing solutions add accuracy and eliminate further steps in the inspection process.