October 2011

The many applications of 3D laser processing systems make them a useful and economical tool for manufacturers everywhere. In this primer, Frank Geyer of TRUMPF not only examines their capabilities and limitations, but shares some useful tips for challenging applications and reviews some opportunities that you may not be familiar with.

Welding filler metal certification, documentation and accountability is frequently a step of the nuclear pressure vessel fabrication and military shipbuilding process. Regis Geisler of Lincoln Electric explains how to select the appropriate weld testing requirements to verify quality and attest that the products being supplied meet the constituents of the required specification.

Randy Pearson of Siemens Industry explains how innovative CNC technology can now operate sophisticated multi-task machine tools with seamless transitions from mill to turn or turn to mill or both; identical look-and-feel to screens, too!

The many applications of 3D laser processing systems make them a useful and economical tool for manufacturers everywhere. In this primer, Frank Geyer of TRUMPF not only examines their capabilities and limitations, but shares some useful tips for challenging applications and reviews some opportunities that you may not be familiar with.

Recent activities and events going on in the business of fabricating and metalworking.

People making recent headlines in the business of fabricating and metalworking.

German plastics specialist BBG enters a new market by manufacturing an automated bending/hardening system for the production of plows in India.

To meet tighter quality demands and shorter deliveries, John Bornhorst of AIRAM Press explains how this in-motion die-equipped pneumatic press eliminates secondary operations and reduces material handling up to 40 percent when fabricating parts for metal buildings, roofing, grain bins and elevators, as well as truck, automotive, appliance and HVAC applications.

It is useless to worry about whether the economy is getting better or worse. Instead, focus on out-marketing your competition. Here are several effective ways to do just that.

A TwinLap Welder from Taylor-Winfield has been selected for one of the most advanced continuous annealing processing lines in North America at PRO-TEC Coating Company, the joint venture between Kobe Steel and U.S. Steel.

Woven metal fabric from GKD-USA is the secret behind the display and the façade that hides the 1970s-era steel overlay of the Port Authority Bus Terminal, which once earned it the unflattering designation as one of the ten ugliest buildings in the world.

Randy Pearson of Siemens Industry explains how innovative CNC technology can now operate sophisticated multi-task machine tools with seamless transitions from mill to turn or turn to mill or both; identical look-and-feel to screens, too!

A large market has developed for low cost CNC plasma cutting machines used by hobbyists and homeowners, small welding shops, and even maintenance departments of larger companies to cut precise parts in house without breaking the bank. These machines can provide great performance at even better prices, but make sure they fit your needs. Jim Colt of Hypertherm examines what you need to look for.

A Better Idea: At one major aircraft manufacturer, production problems occur in all sizes. This flexible manufacturing system from Bertsche Engineering solves them all by handling parts up to 240 in long and replacing three machining centers – that’s right, three – in a difficult “one off” work environment.

Software developer for programming machine tools, GibbsCAM, reaches another landmark by developing its 1000th MTM (multi-task machine) post processor.

Changing Gears: A 13-year-old student visits gear manufacturer Forest City Gear to explore future career options and, while there, learns about the European education model along with some interesting insights from many women she meets that are already succeeding inside “a man’s world.”

One Stop Shop: By turning blanks and cutting gear teeth all in one setup, this multi-process machine tool from MAG increases productivity and return on investment by reducing setups, part transfers, processing time and space requirements. The system uses pallet changing and automatic tool changing for the highest productivity.

New products have expanded the right angle grinder’s use, but they have also added some complexity to the selection process to match the right product to the right material and application while meeting the criteria most important to the end user. Dave Long of Norton Abrasives shares some helpful selection tools to simplify the process.

Modern wire feeders remove the guesswork that leads to inconsistent welding results. They can simplify the welder’s job and improve productivity. If it has been some time since you last upgraded your welding equipment, Bob Bitzky of ESAB recommends that you examine these five areas of advancements before purchasing your next wire feeder.

Welding filler metal certification, documentation and accountability is frequently a step of the nuclear pressure vessel fabrication and military shipbuilding process. Regis Geisler of Lincoln Electric explains how to select the appropriate weld testing requirements to verify quality and attest that the products being supplied meet the constituents of the required specification.

A large market has developed for low cost CNC plasma cutting machines used by hobbyists and homeowners, small welding shops, and even maintenance departments of larger companies to cut precise parts in house without breaking the bank. These machines can provide great performance at even better prices, but make sure they fit your needs. Jim Colt of Hypertherm examines what you need to look for.

Fabricators often need to weld out-of-position when working with large/heavy weldments and with pipe, which requires adjusting the electrode angle, puddle manipulation, body position and equipment settings. In the conclusion of this two-part series, Ken Alrick of Thermadyne focuses on stick welding mechanics and shows operators the variables that can help them control weld puddle and weld bead profile.

The Tough Gun Reamer from Tregaskiss reduces automated MIG welding expense, speeds set-up and lowers downtime by quickly cleaning and removing spatter.

Here are some descriptions of common TIG mistakes and basic tips on how to prevent these errors from happening.

Deciding whether to convert manual or semiautomatic arc welding stations over to robotic welding is typically driven by the payback or return on investment achieved through labor savings. But Geoff Lipnevicius of Lincoln Electric explains that labor savings do not comprise the total anticipated savings and shows how they are generated from a variety of other process-related areas.

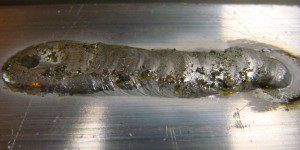

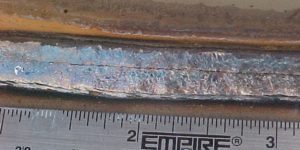

The best defense against weld cracking is to understand its causes and solutions. And he shows why the best place to start is by understanding hot cracking and cold cracking.

Because they affect both machining precision and the service life of the metalworking fluid, slideway lubricants are integral to the productivity of modern machine shops. Here are some tips from Mobil Industrial Lubricants on selecting the correct slideway lubricants for your application.

1PH8 induction motor drives and servomotors from Siemens Industry range from 2.8 kW to 1340 kW for excellent dynamic response, smoother operation and lower vibration levels.

When a machine spindle goes down, much more is involved than simply the bottom-line review of a repair bill or the purchase price of a new spindle. Additional underlying costs include more than dollars. Ed Zitney of SKF Machine Tool Services examines what you can do to help save time and money when a good spindle fails.

These safety systems from Omron STI, Tapeswitch, NoTrax and Pres-On maintain full visibility of and access to the work area while offering freedom, flexibility and reduced operator fatigue when compared with traditional guarding methods such as interlocked fences, pullback restraints or perimeter barriers.

Lock It Shut: The very compact D4SL 6-contact guard lock safety door switch from Omron STI combines simple and flexible installation with robust operation to satisfy the varying safety needs of today’s door access applications.

Properly engineered air collection and filtration systems not only improve plant air quality, they can help welders become more productive and reduce expensive welding mistakes and rework. Jorgen Brahm of Clean Air America examines a filtering technology that improves air quality at a low filter replacement cost for welding operations.

After a process is stable and compliant, safety should focus on worker and process capability by diverging into worker skills and equipment maintenance. Phil La Duke of Rockford Greene reveals why there is no need to spend lots of time trying to improve workplace safety through worker training and total productive maintenance when there are many other low-cost actions that can be quickly deployed.

When highly deformable workpieces need processing, conventional 3-jaw chucks quickly reach their limits. This primer from Schunk identifies different clamping tools and devices for deformation-free workpiece clamping and the criteria they should meet to demand efficiency and precision.

For larger, heavier work pieces that require beefier locating and clamping hardware from Stevens Engineering these tombstones, two-sided angle plates, angle plates for horizontal spindle applications and subplates for vertical spindle machines can all be sized to meet customer needs.

Super Turbo chamfer mills from Seco Tools provide high metal removal rates on steel, stainless steel, cast iron, hardened materials, high-temperature alloys and non-ferrous materials while reducing production costs, allowing manufacturers to increase the versatility of their operations without additional spare parts.

Cimtech 310® low-PH synthetic metalworking fluid from Cimcool Fluid Technology meets the strict requirements of automotive and aerospace manufacturing and is ideal for creep feed grinding on non-ferrous or ferrous metals.

Explore how advances in on-machine measurement technologies from FARO Technologies have helped Ontario aerospace supplier Express Manufacturing realize a full and quick return on investment.

An RMP600 strain-gauge machine-tool probe from Renishaw has the right touch for form measurement of 5-axis aerospace parts and enables a portal mill that uses on-machine verification software to double as a CMM at Triumph Fabrications.

Instead of dedicating a static CMM located away from the point of manufacture, BMW combines the portability of Zett Mess inspection arms with PowerINSPECT software from Delcam to make many more prototype inspections possible.

This direct connection between MoveInspect HR from AICON 3D Systems GmbH and PowerINSPECT from Delcam offers a great advantage: before beginning data collection, a measurement plan can be created in the analysis software to prescribe the measurement procedure in a detailed way, guiding even inexperienced users through the measuring-process smoothly.

When a rebuilt CMM from the 1970s that was being used for gear inspection lost its repeatability, specialty transmission manufacturer Cotta Transmission replaced it with a Wenzel bridge-type CMM from Xspect Solutions that was equipped with inspection software and a level of basic gear measuring capability that optimized the inspection process and improved measurement variation by over 200 percent.