October 2019

Digital Issue

The 2019 edition of FABTECH will be one of the largest metal fabrication events ever at McCormick Place in Chicago from November 11-14. This special Show-in-Print provides technical reviews of some of the machinery, tooling, systems and accessories that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Subscribe View Digital IssueWithout a means to accomplish certain in-house machining easily and consistently, this handrail manufacturer was sending out a huge chunk of work – leaving their commitment to ship dates, lead times, costs and overall project control out of their control. A trip to FABTECH changed all that.

Filler metal used in welding pressure vessels must provide the appropriate impact toughness to meet strict design temperature requirements. Let’s examine the challenges of finding filler metal combinations, along with obtaining necessary documentation or testing to support welding procedures that can meet the mechanical properties of A516 Gr 70 plate.

Building the Smart Factory starts with digital processes and automated machines, but it ends with intelligent connections between resources and tasks. Linking together people, machines and software inside a plant enhances the capabilities of each and creates a system that is more valuable than the sum of its parts.

Here are some of the forming and fabricating tools, machinery and systems that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Here are some of the metalforming tools, machinery and systems that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Here are some more of the metalforming tools, machinery and systems that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Here is some of the tube and pipe fabrication equipment that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Here are some of the finishing tools, systems and accessories that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Here are some of the additive manufacturing systems that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Here are some of the robotics and automation that will be exhibited to help you navigate the show floor and manage your time while you’re there.

The Model No. 841 from Grieve is a 650 deg F universal oven that can be used for a variety of heat treatments.

Building the Smart Factory starts with digital processes and automated machines, but it ends with intelligent connections between resources and tasks. Linking together people, machines and software inside a plant enhances the capabilities of each and creates a system that is more valuable than the sum of its parts.

As you prepare for FABTECH 2019, you might ask: Is this event a good place to shop for software? Yes! Here’s why.

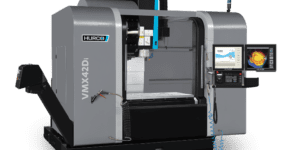

VMXDi Series vertical machining centers from Hurco feature a direct-drive spindle and boast a better surface finish, quieter spindle, less head growth and faster accel-decel rates.

Without a means to accomplish certain in-house machining easily and consistently, this handrail manufacturer was sending out a huge chunk of work – leaving their commitment to ship dates, lead times, costs and overall project control out of their control. A trip to FABTECH changed all that.

Here are some of the welding tools, machinery and products that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Here are some more of the welding tools, machinery and products that will be exhibited to help you navigate the show floor and manage your time while you’re there.

Filler metal used in welding pressure vessels must provide the appropriate impact toughness to meet strict design temperature requirements. Let’s examine the challenges of finding filler metal combinations, along with obtaining necessary documentation or testing to support welding procedures that can meet the mechanical properties of A516 Gr 70 plate.

Welding and fabrication are complex processes that can greatly benefit from robotic automation. While each application will differ in complexity, the consistent and effective use of certain weld functions can improve quality and enhance productivity while decreasing costs.

With its low surface tension, D-Greeze 500 from Solvent Kleene easily removes lubricating oils, grease and other contaminants from blind holes, small orifice openings and other tight surfaces after machining.

The new Model 1050 continuous-duty industrial vacuum cleaning system from Vac-U-Max effectively vacuums high-density materials, such as steel shot, grit, cement, foundry sand and other similar materials.

The versatile, economical Pramet ISBN10 cutter from Dormer Pramet is suitable for high feed milling, copy milling, ramping, helical interpolation, slotting and plunging. Its unique pocket design, in combination with the ANHX10 insert, also performs shoulder and face milling to provide a complete package for mold and die applications, from roughing to finishing.

Considering where a standard item’s functionality ends, there are endless possibilities. Yet even when budgets, and in some cases physics, get in the way, the only true limit is one’s imagination.

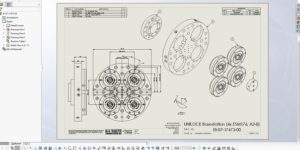

Part complexity, tougher quality requirements, and calls for 100% parts inspection are on the rise, straining the capabilities of conventional 3-axis coordinate measuring machines (CMMs). Adding A and B axes via the industry’s only multisensor probe to a CMM’s X, Y, and Z axes increases surface speed and shortens measurement cycles.