October 2020

Digital Issue

Safe Shops: Factory Operations in the Pandemic. Until there's a vaccine, fabrication and machining companies must continue taking extra precautions to protect the physical and mental health of employees and their families. We share best practices for floor layout, scheduling, sanitation, testing and monitoring, and communications.

Subscribe View Digital IssueA small Ohio company outpaces its market with new expertise and a new compensation system.

One of the fastest-growing sectors of North American metal manufacturing is laser processing of tubes and profiles. Design software and machines that automatically perform multiple manufacturing steps are making this complicated fabrication process cost-effective for smaller companies.

Being sprayed with searing-hot drops of melted metal is one aspect of the job no welder relishes. Following these five productivity, quality, and cost-saving tips will produce better-looking welds with less mess.

A small Ohio company outpaces its market with new expertise and a new compensation system.

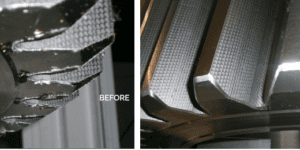

Unlike conventional grinding, wire EDM, and lasers, Tridex Technology’s SG-1645 and SG-2060 electrochemical grinders quickly provide a burr-free cut in one pass with no heat-affected zone, recast layer, or work hardening of the material. Arthroscopic shaver teeth are commonly produced by conventional abrasive grinding, wire EDM, or laser cutting, but each method has disadvantages.

With its 9-inch-wide footprint, Midwest Automation’s Mighty 9 finishing machine fits virtually anywhere on a shop floor. Fixed belt (FB), adjustable belt (AB), and top brush (TB) abrasive head assemblies provide flexibility by allowing multiple combinations.

Helios Gear Products adds CNC capability to Tecnomacchine (TM) deburring and chamfering machines to improve repeatability, programmability, and ease of use. The TM 1000-CNC’s 8 axes and two spindles handle parts up to 40 inches (1 meter) in diameter.

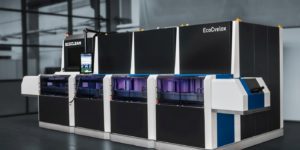

Combining high-pressure water jet deburring with low-pressure part cleaning and drying processes, the EcoCvelox from Ecoclean Inc. is a one-stop finishing solution. Highly configurable equipment enables highly flexible process design.

By rotating media instead of parts, Bel Air Finishing’s AutoHone robotic deburring machine eliminates scrapes and chips that occur when parts collide with each other in tumblers and centrifugal disk finishers. Parts are secured for deburring and polishing in an automated process.

One of the fastest-growing sectors of North American metal manufacturing is laser processing of tubes and profiles. Design software and machines that automatically perform multiple manufacturing steps are making this complicated fabrication process cost-effective for smaller companies.

Robotic welding cells with arc-monitoring and -reporting capability provide peace of mind in two ways. They ensure consistent production and automatically collect and store data a fabrication company can easily share with customers that impose traceability requirements.

Deburring ensures parts fit perfectly during welding or final assembly. This leads to higher-quality products and more efficient workflows that will save your shop time and money – and improve its bottom line.

Why buy a new machine when you can convert an existing piece of equipment for much less money? Somex MAX spindles and accessories can be added to transfer machines, special-purpose machines, and turning machines to perform deep hole drilling.

VFD and VFD Plus kits from Servo Products convert older step pulley mills and worn-out variable-speed mills to smooth, electronic speed control. Unlike early VFD kits, these provide full torque at the lowest RPM.

A line of machines from 101-year-old tool builder and workholding manufacturer Palmgren features Fagor Automation controls that make programming easy for any level of operator producing any size batch.

With its powerful performance, lightweight size, small footprint, and hole capacity, the HMD904 is the most popular model in Hougen Manufacturing’s line of magnetic drills. Upgrade improve safety and lower maintenance requirements.

Designed for turning machine tools with up to two axes, TURNPWR control by Heidenhain’s Acu-Rite brand of digital readouts, linear scales, and controls gives machinists the option to program via a conversational format or use G-code.

Understanding the application and being aware of common challenges can help make a difficult operation both productive and profitable. An ANCA product manager explains the different types of cutting tools for deep hole drilling and how to overcome common challenges.

Robotic welding cells with arc-monitoring and -reporting capability provide peace of mind in two ways. They ensure consistent production and automatically collect and store data a fabrication company can easily share with customers that impose traceability requirements.

Being sprayed with searing-hot drops of melted metal is one aspect of the job no welder relishes. Following these five productivity, quality, and cost-saving tips will produce better-looking welds with less mess.

Designed for use with submerged arc, TIG and MIG welding applications, Koike Aronson’s Cricket-II manipulator features a load capacity of 500 pounds, CAM roller guidance, and through-the-boom cable management.

Robotic welding is much more common for automotive applications than structural steel, where beam weight and variability vastly complicate handling and programming. To combat skilled-labor shortages, a North Carolina fabricator is using PC-controlled hardware that automates programming.

The Environmental Protection Agency (EPA) maintains a list of disinfectants that kill SARS-CoV-2, the coronavirus that causes COVID-19. Madison Chemical’s Madisan 75 kills a wide range of pathogens in addition to SARS-CoV-2.

Graphic Products’ PathFinder floor-marking tape is an easy and inexpensive way to reinforce best practices for minimizing the spread of infection on the shop floor and common areas. Unlike paint or permanent barriers, tape is applied within minutes and removed when needed.

The ANT-FR-Q9 from Antlia Systems combines facial recognition technology with no-contact temperature detection to provide a complete access-control health security system. It’s just one in the company’s suite of out-of-the-box screening systems.

Manufacturers no longer wonder when the pandemic is going to be over, but how to profitably interact with customers and suppliers in a way that protects the health of employees, their families, and the local community. As ever, U.S. metal fabricators and machining companies are highly resourceful.

The MC025 Advance and MD025 Supreme cutters from Walter feature high cutting speeds, exceptional reliability, and universal applicability.

With Solid Edge 2021, Siemens furthers expands the functionality of its product development software suite. Enhancements include new tools for cloud-based collaboration.

Improve roughing operations and achieve superior surface finishes without high machine power consumption with Seco Tools’ Double Turbo line of cutters. Double-sided inserts and superior milling grades significantly lower finishing cycle times.

Sandvik Coromant’s M5C90 milling cutter resolves the challenges of machining lightweight aluminium by roughing and finishing in one pass cylinder heads, cylinder blocks, and other automotive components formerly made from heavier cast iron alloys.

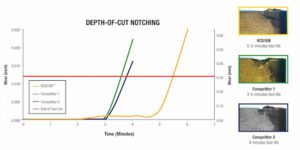

Armed with a special coating and proprietary sputtering technology, Kennametal’s KCS10B overcomes the most common challenges of machining superalloys — cratering and depth-of-cut notching — that often cause unexpected and even catastrophic tool failure.

Hoffmann Group expands its family of high-feed-rate milling tools with the Garant Power Q Double all-round system. Three-part cutting edge increases reliability and productivity by reducing cutting forces and optimizing chip evacuation.

The dual-contact grip of Big Kaiser’s fullcut mill contact grip is a threaded coupling system that achieves machining capacity close to that of integrated types. The taper and flange face make close contact for solid connection, and one holder allows selection from multiple heads.

Founded in 1896, Bico Steel prides itself on being a value-add supplier of steel plate and forged steel blocks. Switching bandsaw blades helped the Michigan company prove its worth when asked to quickly deliver product for ventilators early in the pandemic.

Shops can save time and money — and reduce safety risks — when products are used properly. Here’s what to look for and how to correct it to get the most life out of yours.

OmniScan phased array ultrasonic testing (PAUT) instruments are known for power, reliability, and ease of use. Whether inspecting pipes, welds, pressure vessels, or composites, the OmniScan X3 flaw detector from Olympus enables users to complete their work efficiently and interpret flaws with confidence.

Two NVision Inc. projects demonstrate the growing role of noncontact scanning/measurement technologies in the race to create new products that minimize exposure to the novel coronavirus.

Confirm tolerances without gauge remastering with the Aeroel MECLAB.T40 from Marposs. The benchtop laser measurement system doesn’t require a PC, so it’s ideal for use on the shop floor.

Equipped with a 16-bit high-dynamic-range (HDR) camera, Mahr’s updated MarSurf CM mobile optical surface metrology tool offers the highest-speed, highest-resolution confocal measurements on the shop floor and in the field.

The developer claims its Inspekto S70 is the first truly autonomous inspection system. Driven by artificial intelligence engines that use good samples to identify noncompliant parts, the Inspekto S70 installs in minutes and is about one-tenth the cost of traditional machine vision solutions.

As micro-processing quality requirements become more demanding, legacy systems don’t always meet accuracy and repeatability specifications. Built around ALIO’s 5-axis laser gimbal, 6D Laser’s integrated infinite field of view (IFOV) system increases processing speed while eliminating errors from field stitching.

The scalable 3D quality inspection (3DQI) joins the FlexArc and FlexLoader in ABB’s growing portfolio of smart and flexible solutions. Designed to accelerate testing of automotive, aerospace, heavy machinery, and construction workpieces, the hardware/software solution also enhances quality and reduces waste.

Part complexity, tougher quality requirements, and calls for 100% parts inspection are on the rise, straining the capabilities of conventional 3-axis coordinate measuring machines (CMMs). Adding A and B axes via the industry’s only multisensor probe to a CMM’s X, Y, and Z axes increases surface speed and shortens measurement cycles.