October 2022

Digital Issue

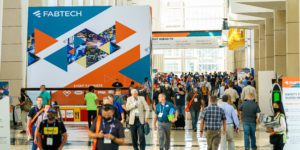

FABTECH 2022: Where Innovation Meets Opportunities. FABTECH is North America’s largest metal forming, fabricating, welding and finishing event. At this annual gathering attendees can view the latest machinery and software innovations and find the tools and new solutions that will assist them in improving productivity and increasing profits. Many exhibitors will unveil new or updated machinery or products and services at this event.

Subscribe View Digital IssueWelding, robotics and automation will be featured at Fabtech in Atlanta.

3D and additive manufacturing solutions will be displayed at FABTECH.

FABTECH 2022’s attendees can view the latest machinery and software innovations and find the tools and new solutions that will assist them in improving productivity and increasing profits. Many exhibitors will unveil new or updated machinery or products and services.

Disruption, good or bad, is a factor when conducting business. Ensure your shop is financially prepared to deal with the challenges and the opportunities.

Welding, robotics and automation will be featured at Fabtech in Atlanta.

3D and additive manufacturing solutions will be displayed at FABTECH.

AMADA’s sheet metal fabrication equipment assists end users in generating more product by utilizing their existing workforces.

From its worldwide leadership in metal band saw and cold saw technology to its long-term, driven employees, HYDMECH’s machines offer users a competitive edge.

These small but powerful machines help small fabrication shops leverage their workforce to be more productive, and they complement the big, advanced production systems found in more automated factories.

Welding, robotics and automation will be featured at Fabtech in Atlanta.

Taking the time to carefully plan for this investment is important. Look to a provider for assistance and for help determining the expected payback.

These small but powerful machines help small fabrication shops leverage their workforce to be more productive, and they complement the big, advanced production systems found in more automated factories.

Company utilizes JM Performance Products’ High Torque retention knobs, which eliminate the toolholder expansion responsible for costly CNC milling and boring issues.

3D and additive manufacturing solutions will be displayed at FABTECH.

![AMADA AMERICA, INC, AMADA AMERICA, INC., AMADA AMERICA, AMADA, Jason Hillenbrand, Joe Amico, EVS Metal, Michael Weiss, Weistec Engineering, advanced metalworking solutions, lasers, turret punch presses, press brakes, sheet metal fabrication equipment, turret presses, punching, punch laser technology, punch laser, punching machines, auto-tool changing press brakes, EVS Metal, HG 1003, Weistec Engineering, AMADA [VPSS]3i software, metal fabrication industry](https://neighborly-cakes.flywheelsites.com/wp-content/uploads/2022/10/Weistec_BREVIS_1212_AJ_Doors_Open1-300x150.jpg)