October 2023

Digital Issue

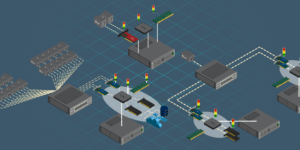

Prepare for the Future with Robotics & Automation. Exploring the addition of automation to your metalworking operation can be an intimidating task. With the growing ease of use and affordability of this equipment, more operations are becoming interested in automation, especially for high-mix, low-volume applications. In this issue, FANUC's Larry Marino explores the top 10 questions to ask when considering the purchase of a machine tending cobot for your facility. The cover story also includes the latest from robotics and automation product suppliers regarding their innovative products and cloud platforms and the role they will play in the future of metalworking.

Subscribe View Digital IssueAdopt technologies that handle market pressures and empower workers to ensure your long-term success.

Ten questions to ask when considering a machine tending cobot.

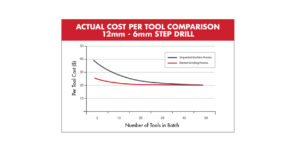

Save time with continuous production from bar stock to finished tool.

The value and importance of Industry 4.0 equipment and technologies results in efficiency, accuracy and happy customers.

The advent of turnkey and completely integrated coil-fed laser processing systems promises to enable serious reductions in part costs.

Save time with continuous production from bar stock to finished tool.

Leading-edge CAD and CAM software solutions optimize machining processes and decrease waste.

Adopt technologies that handle market pressures and empower workers to ensure your long-term success.

Innovative welding processes empower your shop to do more with your existing workforce.

Understand the truth about the following seven robotic welding myths.

Machine tending solutions safely expand the reach and payload capability of cobots.

The use of compliant and innovative safety systems and equipment minimizes hazards in your operation and keeps employees safe.

For shops looking to convert to coolant-through tooling, retrofittable systems are one way to go.

Powerful, precise and reliable shrink-fit tool holders secure cutting tools to enable highly accurate and top speed machining.

Enhance your cobot’s versatility with lightweight, automatic tool changers that include several configuration options.

Versatile and fast video inspection systems speed up the process of peeking into your processes, while maintaining maximum efficiency.