September 2014

From product design and prototyping to metal fabrication and assembly, companies need an expert, all-in-one supply chain partner to help them take their business strategy to the next level.

The entire machining process chain can now be run in art-to-part simulation, with feedback and corrections made from end-to-end.

Knowing some basic details about fume extraction guns, as well as good technique for using them, can help welders gain the best performance from this equipment.

From product design and prototyping to metal fabrication and assembly, companies need an expert, all-in-one supply chain partner to help them take their business strategy to the next level.

The new P230B from Marvel Manufacturing is ideal for high production machine and features a 9 in maximum capacity on rounds and a 6.3 in maximum capacity on squares.

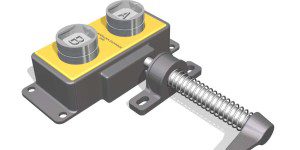

Along with adjustable piston stroke distance, central lubrication systems, electrical back gauges, working lights and five individual workstations each machine, these seven new ironworkers from Marvel Manufacturing offer punching and shearing tonnage ranging from 50-192.

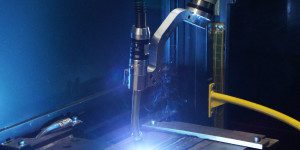

Intelli-CAM from OMAX seamlessly generates tool paths from 3D models and further simplifies the cutting of complex, precision parts.

Competitors in this demanding hotbed of manufacturing are being pushed to find new ways of producing more complex parts. Here are some systems that can help them meet their needs.

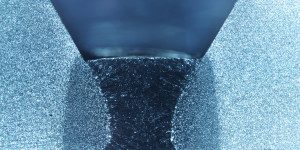

This shop shows how to strike an ideal balance between the powerful roughing and ultra-precise finishing that is required to make turbine blades by building a five-axis turn-mill center that combines robust machine construction with high-quality drive and control engineering.

The entire machining process chain can now be run in art-to-part simulation, with feedback and corrections made from end-to-end.

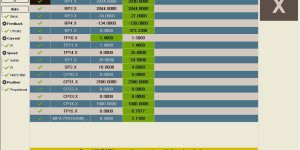

FactoryWiz DNC from Refresh Your Memory provides full simultaneous communication and full machine event/monitoring on every machine tool, with powerful remote-request and email capabilities from the machine control panel, mobile devices and more.

Built for the Cloud, Factory Track from Infor provides manufacturers with a comprehensive, easy to customize way to increase their operational efficiency and improve visibility across the warehouse and the shop floor.

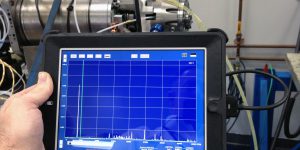

The Auto-Tuning program from Fagor Automation fine tunes machine tool servo drives one axis at a time, all axes automatically, or even multi-machine tuning.

In partnership with Sandvik Cormant, Gibbs and Associates offers GibbsCAM® software integrated with the Adveon™ Tool Library so that users can work with tools from any supplier with accurate geometric information.

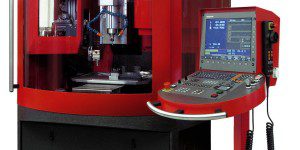

The Ultra Precision EVO CNC Machining center from KERN Precision is equipped for 3-5 axis nano-precision machining of medium to large production lot sizes.

Here are four key strategies that will help welding managers, particularly those new to the job, keep their shops competitive by increasing their production while keeping costs low and quality on par.

As an increasing number of jobs require electric preheat, the ability to use induction heating while welding rolled pipe can benefit productivity, quality and safety and provide fabrication shops a viable alternative.

Knowing some basic details about fume extraction guns, as well as good technique for using them, can help welders gain the best performance from this equipment.

The lightweight, highly portable MiniArc161LTS power source for GTAW/Stick welding and PowerCut® 400 manual plasma cutting system systems from ESAB are ideal for transport on or offsite as the job demands.

Not every welding application on a jobsite can be transitioned over to wire, but noticeable productivity and quality gains can result from switching some of them to wire processes.

A new algorithm uses the high processing power, large memory, extremely fast system bus and highly dynamic wire feed speed of the latest MIG/MAG power source platform to ensure an extremely stable arc with minimal spatter.

A diesel engine-driven welder/generator with dual-operator capabilities is one fuel-efficient machine that provides a full range of jobs and options for multiple users on the service truck or the jobsite — all without sacrificing arc quality or productivity.

Outsourcing preventive maintenance frees your staff to focus on core competencies while leaving this critical function to expert providers.

Here are six top tactics that will help your shop save money by preventing machine failure.

Regardless of the machine tool or system, it is wise to invest time in preventative maintenance as prescribed by the manufacturer. With proper care, it is easy to keep machine tools functioning at their maximum performance level – saving shops time and money in the long run.

A new 12-page brochure from Mencom contains detailed information on their latest industrial connectors.

CECOR offers the unique F23-S filter for the SA5-175PT Sump Shark® that removes garnet from accumulating in dead spots that drop-in hose systems miss or that settles too quickly for filtration systems to catch.

The broader view of business sustainability explores ways to reduce the carbon footprint, use resources more efficiently, and use less resources overall. But most important, it stops wasting precious time, money, and resources on processes that can hurt workers.

Trapped key interlocks for power isolation from Tapeswitch are configured for machine guarding and lock-out on hinged and sliding doors, gates and fences.

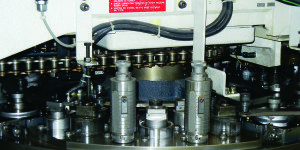

These technical reviews examine some of the latest innovations in quick change tooling and

workholding that can help improve the profitability of your shop.

Take a look at how this job shop uses a highly versatile modular quick change collet system to perform setups and changeovers in speeds of 15 seconds or less.

Tooling changeover is a priority for this sheet metal job shop, which achieves quick setups, extra durability and increased uptime by using advanced tooling that makes its turret presses “operate like new.”

By evaluating and tracking abrasive performance, combined with taking the time to select the best abrasive for a particular application, job shops and production operations can identify opportunities to significantly decrease grinding costs and increase productivity.

The Turbo-Burr from Heck Industries weighs only 3 lb and uses a standard carbide burr to remove burrs on very thin materials up to large blocks.

Vargus offers the TMSD Vertical tool for small diameter deep-hole thread milling applications and TMSD inserts for American Buttress.

Ideal for production machining, the OML Genius 5-axis vise from Lexair pulls jaws together at the top to clamp down the workpiece with a 9,000 lb force that eliminates issues faced with traditional vise jaws.

The RSX Radius Mill Cutter from Sumitomo is ideal for cutting costs in a wide variety of applications, including face milling, ramping, slotting, 3D interpolation and helical boring.

The free-standing Elbo Controlli 66B and 68B tool presetters from Koma Precision eliminate the need for adapters and the errors associated with their use.

New 60-grit premium red aluminum-oxide honing stones from Sunnen are a low-cost alternative to superabrasives for applications where fast, base-metal removal is critical to enlarging a bore in a short cycle time.

By linking CAM software into an advanced tool presetting system, this airline manufacturing unit efficiently manages a large tooling database and machining simulation on highly complex aircraft parts to quickly respond to market changes.

The new generation Artis CTM V6 system from Marposs monitors the machine tool, tooling, coolant flow and related process operations to safeguard and enhance complex machining applications, such as gear hobbing, deep hole drilling and more.