September 2018

Digital Issue

Right now, the U.S. construction market is a great location to be in for metalworking business. And there’s no end in sight – which is good news for suppliers of heavy equipment, assemblies, parts and services used in construction projects and the off-road machinery market sector that includes bulldozers, concrete mixers, cranes, dredging machinery, pavers, power shovels, forestry equipment and more. Also inside: A special Sneak Preview of FABTECH 2018.

Subscribe View Digital IssueNot all conveying systems are suited for every scrap-handling application. By using the proper conveyor to quickly transfer scrap and coolant from the machine tool for separation and processing, high volume machine shops can increase part production with less downtime between jobs, create more value for their scrap, and improve revenue by recycling coolant.

What if you could obtain high quality welds outdoors without the productivity slowdowns associated with changing stick electrodes? Self-shielded flux-cored wires allow welders to continue working without interruption. These wires have changed and improved from what was available several years ago, but you must understand how to select the best wire for the job.

Sheet metal has a high strength-to-weight ratio and good malleability that can provide form and structure to products, but because it is flat and bends easily, it doesn’t always work. Here are some ways to increase the structural strength of flat sheet stock without adding gussets or increasing the weight of the product.

The 2018 edition of FABTECH is on track to be one of the largest metal fabrication events ever at the Georgia World Congress Center in Atlanta from November 6-8. This special sneak peek provides technical reviews of some of the machinery, tooling, systems and accessories that will be exhibited to help you get a head start on navigating the show floor and managing your time while you’re there.

Right now, the U.S. construction market is a great location to be in for metalworking business. And there’s no end in sight – which is good news for suppliers of heavy equipment, assemblies, parts and services used in construction projects.

Spotting a trend in online shopping very early, this Dutch steel wholesaler and contract manufacturer now uses automated ordering, in-line storage and tower systems for continuous flow operations that have built a unique reputation for fast deliveries of custom-made steel, Inox or aluminum parts in small quantities, with a comprehensive array of services.

In the custom installation of this five-story work platform, the biggest challenge facing WB Industries was not in the design, fabrication and assembly of the platform itself, but installing it inside a secure area with only a single lift point.

Sheet metal has a high strength-to-weight ratio and good malleability that can provide form and structure to products, but because it is flat and bends easily, it doesn’t always work. Here are some ways to increase the structural strength of flat sheet stock without adding gussets or increasing the weight of the product.

Press operation requirements, inspection needs, improved die technology, tool room utilization and lean initiatives are all transforming the way shops compete. But what if you can’t keep the die in the press because of cheap tooling?

The popular 8-Mark-III vertical tilt-frame bandsaw from Amada Marvel now has optional full stroke hydraulic vises to out-perform the competition.

The No. 1045 oven from Grieve safely reaches 1,250 deg F for heat treating, with inner and outer door gaskets, inner gasket seals directly against the door plug and outer gasket seals directly against the front face of the oven.

This machine shop took an unconventional approach to growing into one of the most dependable parts suppliers for a major manufacturer of construction and mining equipment, and now they enjoy a niche that most shops are unable to compete against.

Battery technology that is powerful enough for useful and functional structural steel welding has not been available – until now.

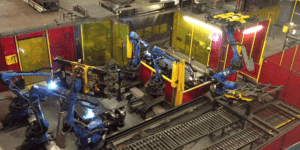

WireCrafters faced a dilemma: Manually welding their stock products had become too difficult to maintain during peak seasons. Hiring temporary welders was expensive. They needed smaller batch sizes and better inventory returns. What could they do?

In the custom installation of this five-story work platform, the biggest challenge facing WB Industries was not in the design, fabrication and assembly of the platform itself, but installing it inside a secure area with only a single lift point.

What if you could obtain high quality welds outdoors without the productivity slowdowns associated with changing stick electrodes? Self-shielded flux-cored wires allow welders to continue working without interruption. These wires have changed and improved from what was available several years ago, but you must understand how to select the best wire for the job.

You’ve got a job that demands high weld quality and appearance. TIG welding will provide you with a greater level of control to achieve those desired results, but don’t overlook the importance of using the correct shielding gas.

Excellence in welding automation relies heavily upon the capabilities of the positioner being used for the application. Selecting the right positioner technology requires a clear understanding of the positioner options and features that are available to gain the flexibility you need to improve weld quality and decrease cycle times.

The Soft Grip Super Air Scraper from EXAIR is perfect for removing caulk, sealant, adhesives, tape, paint, stickers, labels, grease, lubricant and difficult to sweep metal chips, flakes or discs.

Not all conveying systems are suited for every scrap-handling application. By using the proper conveyor to quickly transfer scrap and coolant from the machine tool for separation and processing, high volume machine shops can increase part production with less downtime between jobs, create more value for their scrap, and improve revenue by recycling coolant.

The multiple beam SGS Safety Grid System from Banner Engineering creates a grid of two, three, or four light beams that protect personnel from injury and equipment from damage by detecting a body or torso entering a hazardous area.

To eliminate human error and prevent a worker from performing an unauthorized or unsafe operation when machinery is engaged, trapped key interlock safety systems are an advanced method of Lockout/Tagout machine guarding that protect the operator and other employees in the machine area from hazards.

Bent Engineering successfully threaded 60 holes in shale gas blocks made of 17-4PH 900H stainless steel. How did they do it?

An entrepreneurial spirit and vision fuels the innovative drive behind the aggressive growth strategy of this manufacturer of surface treatment technologies.

As the structural steel market looks for ways to make more parts in less time, some shops are finding a better way to manufacture steel beams with bolt holes.

Sheet metal has a high strength-to-weight ratio and good malleability that can provide form and structure to products, but because it is flat and bends easily, it doesn’t always work. Here are some ways to increase the structural strength of flat sheet stock without adding gussets or increasing the weight of the product.

Even though it has been around forever, does the vise have limitations for shops in a competitive marketplace? Do you need to reinvent the wheel to reduce some of its limitations? To evaluate the vise’s viability in today’s manufacturing operations, we need to uncover the most efficient way to apply it.

Press operation requirements, inspection needs, improved die technology, tool room utilization and lean initiatives are all transforming the way shops compete. But what if you can’t keep the die in the press because of cheap tooling?