September 2020

Digital Issue

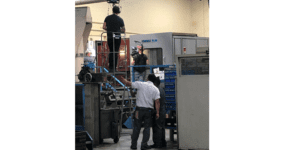

Ready for the Rebound: Decision-Making in Uncertain Times. The global coronavirus pandemic is forcing manufacturers to reconfigure processes and procedures in favor of on-the-fly problem-solving. Faced with a wicked competitive environment before the crisis, this fastener manufacturer and distributor isn't wasting this opportunity to restructure products and services to come out ahead.

Subscribe View Digital IssueWhen the pandemic hit, many companies used the downtime to make data-driven automation, process, and employee training improvements. As global supply chains reconfigure, those investments are paying off.

Contact tips may be tiny, but using the wrong type or replacing them too soon can have a huge impact on productivity. Here’s what to consider to improve results and save money by properly matching tip type to application.

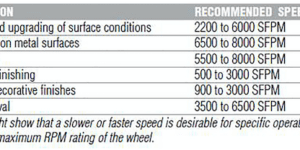

Finding people who are willing and able to press metal against an abrasive belt all day long can be challenging. Nonwoven belts make the job more appealing by increasing productivity without increasing effort.

When the pandemic hit, many companies used the downtime to make data-driven automation, process, and employee training improvements. As global supply chains reconfigure, those investments are paying off.

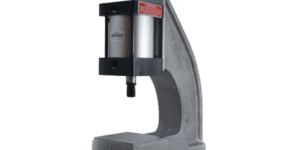

Pneumatic, hydraulic, and electric presses are available in a wide range of models that offer an ever wider range of force, position accuracy, and speed capabilities. Bimba technical experts outline the pros and cons of each press type to make your decision easier.

Nuts, screws, and bolts comprise one of metal manufacturing’s most competitive product niches. As it works to gain market share by capitalizing on pandemic-driven supply chain disruptions, this Illinois fastener manufacturer and distributor illustrates the art of decision-making in uncertain times.

Shaving every second possible from each process is a key objective for high-speed, high-volume manufacturers. Laser marking on the fly helps by recording data on a moving target in milliseconds. Pryor Marking Technology’s Alastair Morris explains.

Dapra Marking Systems introduces the part-marking technology of Spanish manufacturer Datamark Systems to North America. Headlining the new offerings is a series of truly portable dot peen markers.

Walter Helicheck Plus and Helicheck Pro machines from United Grinding North America use robotics to increase the speed and efficiency of cutting tool production and inspection.

SIC Marking’s extremely compact i-speed with pneumatically integrable system uses continuous vibrating dot peen technology to mark up to 10 characters per second in extremely high-speed production environments.

The control unit for the all-in-one Markator FlyMarker mini-Station dot peen marking system from Rocklin Manufacturing is integrated in the housing. Electromagnetic-driven marking pin eliminates need for compressed air supply.

In addition to greater data-processing capability, Pryor Technology’s updated 4000 series embedded controller integrates security features that allow different levels of access and use.

Kwik Mark’s X Series markers improve overall operation and streamline every aspect of product marking. Smarter design boasts high performance for the most demanding applications.

The low-volume Handy Andy X part-marking machine from Columbia Marking Tools (CMT) features wide-ranging advances. Just hook the system up to a PC, load the software, connect an air line, and you’re ready to go.

In addition to faster cycle times and easier setup, Columbia Marking Tools (CMT) bottle- and cylinder-marking machines reduce the need for secondary marking of serial numbers or tare weights. New design also allows more complex operations.

Less expensive than dot peen and laser marking systems, Columbia Marking Tools’ Mite-E-Mark plug-and-play air impact stations come with all required valves, marker mounts, and a part rest to facilitate automated production.

Coherent’s EasyMark XL has a small footprint (770 mm by 540 mm by 750 mm), but a large marking field (240 mm by 240 mm). Beam-delivery optics with 120-mm range of motion on a precision rail for focus adjustment.

What can’t they do? An MC Machinery spokesman demonstrates how press brakes and press brake tools are so multifunctional and adaptable, manufacturers can creatively use them in applications beyond sheet metal and stamping dies.

Sandvik Coromant -RM inserts for CoroCut QD for Y-axis parting enables profiling with long overhangs in narrow grooves, external profiling, the generation of recesses and undercuts, and the potential to use nonlinear turning and grooving with a full radial bottom.

Nine C Series flatbed CNC lathes from Romi Machine Tools are designed for heavy applications in the mining, aerospace, steel mill, and oil-and-gas industries. All key components are manufactured in-house to ensure quality.

Platinum Tooling Technologies expands its product line with Heimatec live and static tools for most Citizen lathes. Designed to optimize the machine’s parameters, the precision tools are efficient and cost-effective.

Available in 5- and 8-inch models, Palmgren’s CNC slant bed lathe offers helpful features and top performance at an attractive price. The turning center’s small footprint makes it an excellent option for shops that need a second-operation machine or additional chuck.

Methods Machine Tools, the exclusive U.S. importer of Nakamura-Tome multitasking turning centers, introduces the Nakamura-Tome MX-100 with multiple ‘smart’ functions that ease programming and operation. Design eliminates need for positioning fixtures and clamping devices.

The Quick Turn 250SMY with GR100 gantry robot is one example of how Mazak’s flexible Quick Turn 200/250 Series of CNC turning centers can be configured to achieve high throughput. Main turning spindle serves as a full-functioning C-axis.

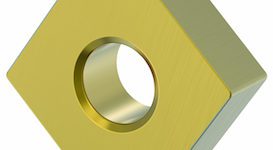

Polycrystalline cubic boron nitride (PcBN) mini-tipped inserts are a great way to lower per-part cost when turning hardened steel components. Kennametal´s two grades of double-sided PcBN inserts increase productivity and extend tool life when machining materials up to 65 HRC.

With its precision interface for fast tool changeover and direct drive for high-power milling of complex workpieces, Emco’s Hyperturn 45 G3 with two Turn/Mill-Assist automation options provides a flexible drilling and milling solution for a wide range of workpiece geometries and weights.

Soft- or hard-machine a bevel gear in 25 to 40 seconds with EMAG’s VL 1 Twin, a pick-up turning machine that simultaneously machines two identical bevel gears at high speed within the same machining area. Automating the loading process lowers cycle time to 4.5 seconds.

Dormer Pramet targets turning center and lathe applications with an insert, two geometries, a grade, blades, and tooling that support parting-off and grooving. Double-edged insert supports 60% capacity over the LCMF16 insert.

DMG MORI and igus spent two years developing the Multisprint, the first machine to combine the efficiency and precision of a turning machine with the complexity of a universal turning machine.

Shaving every second possible from each process is a key objective for high-speed, high-volume manufacturers. Laser marking on the fly helps by recording data on a moving target in milliseconds. Pryor Marking Technology’s Alastair Morris explains.

Dapra Marking Systems introduces the part-marking technology of Spanish manufacturer Datamark Systems to North America. Headlining the new offerings is a series of truly portable dot peen markers.

Walter Helicheck Plus and Helicheck Pro machines from United Grinding North America use robotics to increase the speed and efficiency of cutting tool production and inspection.

SIC Marking’s extremely compact i-speed with pneumatically integrable system uses continuous vibrating dot peen technology to mark up to 10 characters per second in extremely high-speed production environments.

The control unit for the all-in-one Markator FlyMarker mini-Station dot peen marking system from Rocklin Manufacturing is integrated in the housing. Electromagnetic-driven marking pin eliminates need for compressed air supply.

In addition to greater data-processing capability, Pryor Technology’s updated 4000 series embedded controller integrates security features that allow different levels of access and use.

Kwik Mark’s X Series markers improve overall operation and streamline every aspect of product marking. Smarter design boasts high performance for the most demanding applications.

The low-volume Handy Andy X part-marking machine from Columbia Marking Tools (CMT) features wide-ranging advances. Just hook the system up to a PC, load the software, connect an air line, and you’re ready to go.

In addition to faster cycle times and easier setup, Columbia Marking Tools (CMT) bottle- and cylinder-marking machines reduce the need for secondary marking of serial numbers or tare weights. New design also allows more complex operations.

Less expensive than dot peen and laser marking systems, Columbia Marking Tools’ Mite-E-Mark plug-and-play air impact stations come with all required valves, marker mounts, and a part rest to facilitate automated production.

Coherent’s EasyMark XL has a small footprint (770 mm by 540 mm by 750 mm), but a large marking field (240 mm by 240 mm). Beam-delivery optics with 120-mm range of motion on a precision rail for focus adjustment.

McAfee Tool & Die is successful because it’s always ready to take a leap of faith with new technology. When owner Gary McAfee bought a 5-axis machine, he realized it was time to update the shop’s CAD/CAM software.

New York-based Globe Grinding faces the same skilled-workforce gap as other manufacturers. To meet the requirements of demanding aerospace customers, the company is deploying technology current employees can easily learn to program and operate.

With a CE model and 20 additional languages, Lincoln Electric’s PIPEFAB welding system can be used anywhere in the world. Software enhancements including HyperFill mode expand utility and usability for operators and shop managers tracking overall performance.

Huntingdon Fusion Techniques HFT’s blue-tipped MultiStrike tungsten electrodes eliminate the health risk related to radiotoxic thoriated tungsten electrodes without compromising welding performance. They also last longer and offer better arc-striking characteristics.

Amada Weld Tech’s MM-L300A laser weld monitor improves weld performance by giving operators real-time feedback on production errors such as gaps between parts, missing parts, over-penetration, incorrect focus, and cover gas absence. The unit’s software simplifies setup and analysis.

Contact tips may be tiny, but using the wrong type or replacing them too soon can have a huge impact on productivity. Here’s what to consider to improve results and save money by properly matching tip type to application.

Two certified welders who work for a Midwest custom fabricator that designs and manufactures premium architectural systems and components share their tips for avoiding common mistakes that contribute to weld failure.

With the proper process, oil and gas industries that require components to maintain corrosion or cracking resistance can have peace of mind that elevated service temperatures or multiple repair cycles won’t cause damage.

Heating the base metal adds time and money up front, but can save time and money by minimizing potential for weld failure. Here’s how to determine the best preheating method – convection ovens, induction, open flame, or resistance heating – for your application.

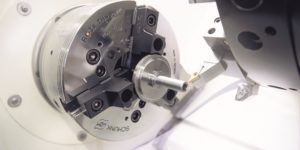

SMW Autoblok’s versatile four-in-one Centco4 2+2 self-centering and compensating chuck minimizes downtime by reducing changeouts and minimizes waste by reducing part deformation.

Sandvik Coromant -RM inserts for CoroCut QD for Y-axis parting enables profiling with long overhangs in narrow grooves, external profiling, the generation of recesses and undercuts, and the potential to use nonlinear turning and grooving with a full radial bottom.

Platinum Tooling Technologies expands its product line with Heimatec live and static tools for most Citizen lathes. Designed to optimize the machine’s parameters, the precision tools are efficient and cost-effective.

Polycrystalline cubic boron nitride (PcBN) mini-tipped inserts are a great way to lower per-part cost when turning hardened steel components. Kennametal´s two grades of double-sided PcBN inserts increase productivity and extend tool life when machining materials up to 65 HRC.

Dormer Pramet targets turning center and lathe applications with an insert, two geometries, a grade, blades, and tooling that support parting-off and grooving. Double-edged insert supports 60% capacity over the LCMF16 insert.

Finding people who are willing and able to press metal against an abrasive belt all day long can be challenging. Nonwoven belts make the job more appealing by increasing productivity without increasing effort.

Featuring a compact outer diameter and shorter than conventional compensating chucks, MicroCentric’s chuck has a collet with a floating seat that enables the holder to compensate up to 0.060-inch (1.5 mm).

EXSYS expands the Eppinger Preci-Flex modular tooling system with a chuck that doubles the machining capability of Mazak’s Quick Turn turning centers. For instance, a tap-and-drill or spot-and-drill combination is easy to set up.

Emuge addresses the increasing complexity of workpieces with a line of FPC Slim Line mill/drill chucks that provide easier access, especially in confined areas and for challenging angles, to maximize machining productivity.

Dillon Manufacturing’s chuck jaws provide multiple radiuses for both inside and outside clamping, making them ideal for any size run. Four jaw and/or accessory options lower tooling costs by increasing productivity and extending service life.

Just as the right workholding can improve your bottom line, inappropriate workholding can eat into profits. Make sure the chuck that came with your lathe isn’t keeping the machine from delivering the throughput and increased capacity it’s capable of.

Amada Weld Tech’s MM-L300A laser weld monitor improves weld performance by giving operators real-time feedback on production errors such as gaps between parts, missing parts, over-penetration, incorrect focus, and cover gas absence. The unit’s software simplifies setup and analysis.

Developed to support both Fanuc and Siemens CNC systems, Marposs Corp.’s software package improves machining operations by automating measurement processes and reporting for the company’s optical and radio touch probes.

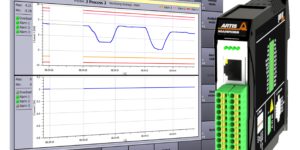

Marposs Corp.’s C-THRU4.0 software collects, processes, and integrates data from a fleet of machine tools via a single hub that integrates with manufacturing execution system (MES) and enterprise resource planning (ERP) software.

Install Marposs Corp.’s Artis GEMGP in electrical cabinets, robots, and handling systems to prevent damage to machines, reduce scrap, and improve productivity by detecting process anomalies during metal cutting.

Hexagon’s cloud-ready HxGN SFx | Asset Management software provides easy-to-understand views of real-time data from coordinate measuring machines (CMMs) with intuitive navigation and a customizable alert system.

The latest version of Faro’s flagship software, BuildIT Metrology, is brand-agnostic to streamline manual and automated workflows regardless of what arms, trackers, scanners, imagers, and/or projectors your shop uses.

A manufacturer’s ability to create a comprehensive, cost-effective digital thread is hindered by legacy and proprietary communications standards. Fortunately, the International Standards Organization is expected to approve the Quality Information Framework (QIF) by the end of the year.