September 2023

Digital Issue

Beyond the Machine: Total Solutions. Okuma America Corp., a world-leading builder of CNC machine tools, controls and automation systems, details how to get started and ramp up with automation in your shop. The company will also outline how best to optimize the automation once it is in place in your shop.

Subscribe View Digital IssueTechnologies available on wheels ensure safe and efficient wheel use, which saves your operation time and money, and increases your shop’s productivity.

In October, the American Gear Manufacturers Association heads to Detroit for three-action packed days, representing suppliers from across the supply chain including gear companies, machine tools suppliers, and electric drive solutions.

Power skiving has revolutionized the gear manufacturing industry by enabling the production of high-precision gears with complex geometries.

ERP software supports your shop in reaching maximum production goals and efficiencies.

Hybrid DED systems will advance and modernize manufacturing to quickly pivot and respond to demands.

Technologies available on wheels ensure safe and efficient wheel use, which saves your operation time and money, and increases your shop’s productivity.

Power skiving has revolutionized the gear manufacturing industry by enabling the production of high-precision gears with complex geometries.

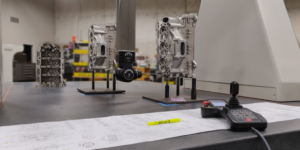

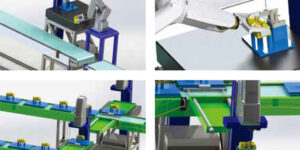

Six steps to successfully adopting CNC automation in your job shop. It’s important for shops to know their baseline productivity to seek out the benefits they’re looking for in order to make improvements.

Machinists are breaking new ground in their performances and processes thanks to the ability to work safely alongside cobots and realize shorter load/unload times.

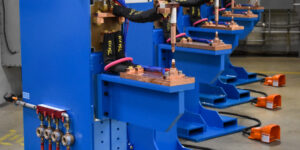

The latest power sources optimize a welder’s arc-on time, and monitor every weld, among other data, to keep up with your shop’s diverse needs.

Robotic cells and automated material handling systems provide compelling solutions to address your shop’s labor shortages.

As the company celebrates its 60th year in business, it is excited about the future of its products and its place in serving the metalworking industry.

Making the right choices when selecting filler metal, shielding gas, wire packaging and incoming material boosts throughput.

Power skiving has revolutionized the gear manufacturing industry by enabling the production of high-precision gears with complex geometries.

Leverage advances in coatings and other technologies and processes to achieve the highest process parameters and productivity.

Tool reconditioning can be an effective and sustainable tooling strategy. It rejuvenates every aspect of the product and returns it to its original manufacturing standard.

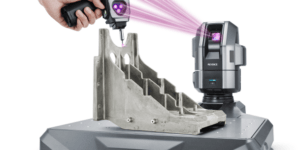

Software and measuring methodology is growing to capture more detail, organize data, and move faster than ever.

Consider migrating from 3-axis to 5-axis CMMs to compete in a digitized market where complex parts have become the norm.

Coordinate measuring machines can help smaller shops stay competitive in a digital age.