Spindle Repair and Rebuilds

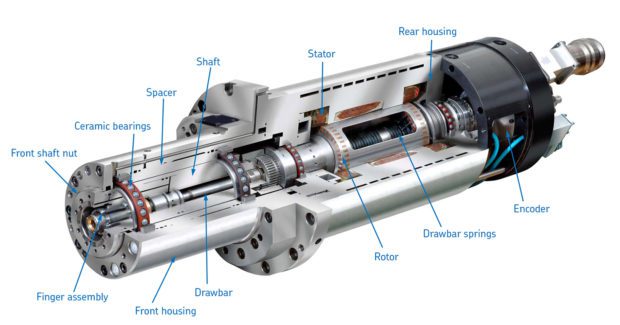

This category includes tools and systems used in the repair or rebuilding of spindles, the rotating axis of a machine, and associated rotating parts. In the fabrication process, this includes belt-driven or electric high-speed spindles used in CNC machines, moulder spindles and arbors. This process includes disassembling, inspecting, testing and rebalancing all rotating equipment, along with testing spindle tool retention and run-off procedure. Systems used in repairing or rebuilding spindles may be used to grind bearings back into proper tolerance or replace bearings, adding or replacing hard chrome, or rebuilding drawbars back to standard clamping pressures.

Prescription for Machine Tool Heart Failure

The spindle is the heart of the machine tool. Its reliability is critical. Should it fail, remanufacturing can enable a practical, quick and cost-effective return to service and productivity.

The spindle is the heart of the machine tool. Its reliability is critical. Should it fail, remanufacturing can enable a practical, quick and cost-effective return to service and productivity.

Industry 4.0 technologies, particularly given their recent price drops, are already shaping up 2018 to be the year where VR, AI and other new and exciting technologies make their way onto the plant floor.

If a spindle breaks down, what is your shop’s plan of action? Is it the most practical and efficient way to deal with a down spindle?

GTI examines the three main factors that must be considered for spindle replacement in critical high frequency ID grinding operations of aerospace and automotive parts.

Take a ‘walk’ around their shop, learn about their machines and in-house capabilities.

E-Z Lok now offers the E-Z Sonic™ with Threaded Insert Assortment kits.

Precision Drive Systems Launches VibeAid℠, where engineers will travel onsite to perform expert vibration analysis on any spindle make and model.

The CenterMaster from INDEX is a system that allows operators with no specialized knowledge or experience to set up a drill in two-to-three minutes. It also provides a repeatable accuracy of <5μm.