Calibration

In the machining process, calibration tools are used to monitor, assess, and improve both the dynamic and static performance of position-critical motion systems. To properly calibrate a device, it is measured under test and compared to a measurement value universally agreed upon as a national standard. While historic calibration techniques only measured displacement of a machine tool along its three axes, modern calibration equipment can detect errors in roll, pitch, and yaw, along with squareness errors, and vertical and horizontal straightness errors. Some modern calibration tools include laser and ballbar systems, multi-axis calibrators, rotary axis calibrators, and machine checking gauges.

Machined Metal Parts: Tips to Ease the Inspection Process

Selecting a videoscope with a suitable scope diameter along with ergonomics and durability can help inspectors stay comfortable and productive.

Selecting a videoscope with a suitable scope diameter along with ergonomics and durability can help inspectors stay comfortable and productive.

Uncover hidden defects before downstream processes are impacted with the latest 3D scanners, powerful software packages and portable measurement devices.

Automated Precision Inc.’s innovations mark a significant leap forward in machine tool calibration, delivering enhanced performance and user convenience.

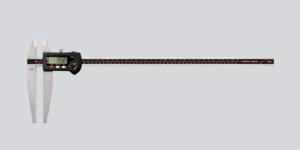

Mahr Inc.’s new MarCal 18 EWR(i) digital caliper features an expanded 800 mm measuring range and integrated wireless connectivity.

Gefran introduces TWIIST, which features a unique helical magnetoelectronic design that allows it to take multiple measurements simultaneously, with a focus on operator safety.