Laser Scanners

This category includes systems and machines that utilize lasers to survey an object, a building, or a landscape, and then translate the data into full three-dimensional digital models of the piece being surveyed. Laser scanners are used in the manufacturing process in rapid prototyping, precision alignment, in material processing such as engraving or laser welding, laser and 3D printers, and for precision inspection, among other uses. Laser printers commonly employ multiple moveable mirrors to steer the laser system, along with a software system to control the scanner’s motion and to collect the resulting data. When paired with a coordinate measuring machine (CMM), laser scanners can be used to record data from larger devices, like automobiles.

Solutions Guarantee Your Shop Passes Inspection and Stays in Balance

Leading edge equipment, technologies and software provide a detailed look into the health and condition of cutting tools.

Leading edge equipment, technologies and software provide a detailed look into the health and condition of cutting tools.

Automated measurements of workpieces in machines are progressively more important in today’s manufacturing processes, resulting in shorter production times and fewer interruptions. What’s more, there is more confidence when it comes to the measurement process.

With the introduction of groundbreaking innovations and first-of-their-kind developments, job shops will find no shortage of 3D metrology laser scanner technologies available to assist them with precision measurements, and the ability to scan parts faster and with greater accuracy.

ColeTech used a Radian 6DoF tracker from API to correct errors in joint angles and link lengths for deflashing molded parts.

Almost every major pipeline owner/operator now either uses a portable LIBS device for verifying their materials or requires their non-destructive testing contractors to use it. Almost every major refinery uses one for carbon testing, as do the inspection companies that support their PMI/NDT programs. Here’s why.

Efficiency-optimizing enhancements unveiled by Evident Corp. on its MapROVER™ and SteerROVER™ corrosion and weld inspection scanners.

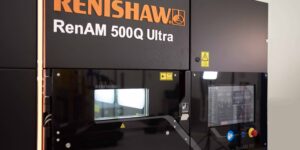

Renishaw’s patented TEMPUS technology enhances the class-leading productivity of the RenAM500 series metal additive manufacturing systems with reduced build times, detailed build insights and advanced process monitoring.

Automated Precision Inc. now offers Dynamic 9D LADAR mounted on an Autonomous Guided Vehicle for use in aerospace manufacturing inspections.