Other Gauges and Gauging Equipment

Metalworking necessitates a wide variety of gauges and measuring equipment, ranging from simple hand tools to precision digital technology. Along with the other measurement and inspection tools listed in this section, this category includes gauges and other instruments used to measure angles, depths and diameters, material hardness and other physical properties, conductivity, pressure and temperature, fatigue and wear, to compare a finished piece against a prototype, and other applications.

Machined Metal Parts: Tips to Ease the Inspection Process

Selecting a videoscope with a suitable scope diameter along with ergonomics and durability can help inspectors stay comfortable and productive.

Selecting a videoscope with a suitable scope diameter along with ergonomics and durability can help inspectors stay comfortable and productive.

Uncover hidden defects before downstream processes are impacted with the latest 3D scanners, powerful software packages and portable measurement devices.

Leading edge equipment, technologies and software provide a detailed look into the health and condition of cutting tools.

Some manufacturers shy away from conducting gage repeatability and reproducibility (GR&R) studies because the results are inconsistent. But because variability is unavoidable, your goal is to calibrate that measuring device to consistently return an acceptable range of results.

ColeTech used a Radian 6DoF tracker from API to correct errors in joint angles and link lengths for deflashing molded parts.

Efficiency-optimizing enhancements unveiled by Evident Corp. on its MapROVER™ and SteerROVER™ corrosion and weld inspection scanners.

With the launch of its Inspector83x 2D vision sensor, SICK has enabled out-of-the-box Artificial Intelligence machine vision inspections for common inline inspection tasks in demanding high-speed production. The no-stress teach-in capability of the SICK Inspector83x can be used by non-specialists…

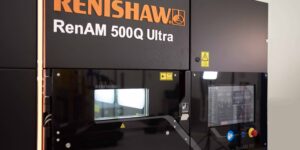

Renishaw’s patented TEMPUS technology enhances the class-leading productivity of the RenAM500 series metal additive manufacturing systems with reduced build times, detailed build insights and advanced process monitoring.