Surface Roughness/Finish

This category includes systems used to inspect the surface integrity of a workpiece after it has been processed by any surface modification process, including forming, metal cutting, welding, surface treatment, or other surface alteration. In the fabrication process, a surface’s roughness is a measurement of the height of irregularities and asperities on a finished surface after machining. ‘Finish’ is not a measurable quality, but depend on the viewer’s perception and the requirements of the task. Devices used to measure the roughness of a workpiece’s surface are called profilometers; manual comparison can also be made against a sample of a known surface roughness.

Machined Metal Parts: Tips to Ease the Inspection Process

Selecting a videoscope with a suitable scope diameter along with ergonomics and durability can help inspectors stay comfortable and productive.

Selecting a videoscope with a suitable scope diameter along with ergonomics and durability can help inspectors stay comfortable and productive.

Uncover hidden defects before downstream processes are impacted with the latest 3D scanners, powerful software packages and portable measurement devices.

Many shops hesitate to incorporate abrasive finishing tools in CNC machines for fear of clogging coolant lines and damaging slides and bearings. However, finishing tools generate very little grit.

To remain competitive, more shops are searching for ways to better utilize their quality workforce and supplement them with automation. But Ken Myers of Mitutoyo America explains that what automating metrology means to one person might not mean the same to another.

This high-intensity, multidirectional lighting camera technology makes easy imaging of challenging part features on machined heads to provide a clear advantage for this automotive supplier.

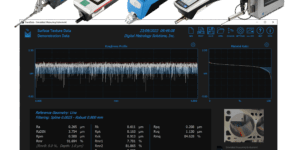

One click in TraceBoss configures the gage, initiates a measurement, and presents the results and graphics full screen and in high resolution.

The handheld device now features a metal housing and readings are from atmospheric oxygen level (20.94%), down to 100 ppm (0.01%) of oxygen.

Renishaw’s multisensor REVO 5-axis measurement system provides highly accurate scanning, non-contact inspection and surface finish analysis at ultra-high speeds on one coordinate measuring machine (CMM).