Touch Probes

Monitoring and Inspection Systems Enhance Analysis and Offer Flexibility

Inspect all of your important parameters and test parts with confidence thanks to enhanced measuring capabilities and products.

Inspect all of your important parameters and test parts with confidence thanks to enhanced measuring capabilities and products.

Automated measurements of workpieces in machines are progressively more important in today’s manufacturing processes, resulting in shorter production times and fewer interruptions. What’s more, there is more confidence when it comes to the measurement process.

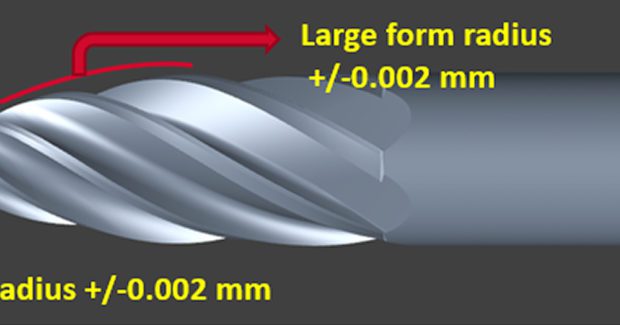

There are three important features to look for when deciding on a touch probe for in-process use.

To remain competitive, more shops are searching for ways to better utilize their quality workforce and supplement them with automation. But Ken Myers of Mitutoyo America explains that what automating metrology means to one person might not mean the same to another.

Here are some of the latest advances in automated measurement that can help improve the productivity and capability of your inspection processes.

Renishaw’s patented TEMPUS technology enhances the class-leading productivity of the RenAM500 series metal additive manufacturing systems with reduced build times, detailed build insights and advanced process monitoring.

Mahr Inc.’s LVDT style measuring probe features a shorter measuring span and higher accuracy for use in dedicated gaging fixtures.

Mahr Inc. introduces the new MarSurf M 410, which provides high precision and accuracy for surface roughness measurements on small and large workpieces.