CAD/CAM Software

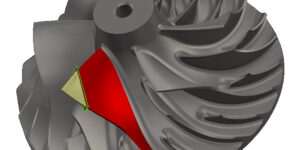

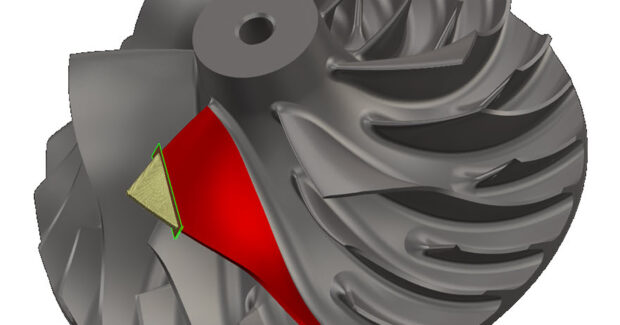

Computer-aided design (CAD) software and computer-aided manufacturing (CAM) software is used to design and manufacture prototype parts, finished products, and production runs. An integrated CAD/CAM system uses CAD software to design models and assemblies of a product and interface with CAM software that references and applies those models and assemblies created in the CAD software to program specific manufacturing processes, perform functional simulation that optimizes each process step, then drive the machine tools used to produce physical parts from the product designs.

The Sum of Its Parts: CAM Plus Additive Equals Powerful Hybrid Manufacturing

A manufacturer that has both subtractive and additive manufacturing capabilities may be better prepared for whatever jobs come along.

A manufacturer that has both subtractive and additive manufacturing capabilities may be better prepared for whatever jobs come along.

Davi Inc. continues to invest heavily in research and development to develop new solutions in plate roll and angle roll machinery.

Discover what’s next for machine tools. It may be just the time to update your shop’s metal removal technologies and processes.

With more than 20 kilowatts of power available, cutting thickness limits can be pushed to as thick as 2”, allowing fabricators to bring the speed, precision and cutting quality of the laser to a new range of parts and products.

Hall D: METALFORM, Finishing, Tube & Pipe of FABTECH 2023, North America’s largest metal forming, fabricating, welding and finishing event.

THOR F integrates plasma and oxyfuel cutting with an optional beveling system, and an optional tube and profile lathe. It also combines plate cutting with edge preparation and numerous mechanical machining operations, including milling, drilling, tapping, countersinking, marking, etc.

The Beamcut System 3D Robotic Profile Cutting Machine cuts any shape from mild steel, stainless steel, and aluminum with high repeatability and accuracy. It eliminates costly layouts and grinding, simplifies fabrication, minimizes errors, and boosts production speeds.

Velo3D’s Flow Developer: From black box to full transparency and control, the new product enables a pathway to migrate additive manufacturing knowledge to VELO3D’s fully integrated solution and print process optimization.