Heat Treating

Heat treatment is the controlled heating or cooling of material to change its structure in order to obtain certain mechanical properties, such as hardness, strength or ductility. Heat treating processes include Annealing, which heats the material slightly above its critical temperature, then slowly cools it to reduce its hardness and increase its ductility. Normalizing cools the heated material in air to remove the effect of all previous heat treatment processes. Quenching heats the material to its critical temperature, then cools it rapidly in water or air to increase its hardness and wear resistance. Tempering reheats a quenched part to a point below its critical temperature, then cools it at a desired rate to increase its ductility and toughness.

Increase Your Productivity with Highly Precise and Accurate Solutions

The most innovative and updated features to today’s metal forming and fabricating machinery, additive manufacturing equipment, software, controllers and accessories result in efficiencies — both in production and cost savings.

The most innovative and updated features to today’s metal forming and fabricating machinery, additive manufacturing equipment, software, controllers and accessories result in efficiencies — both in production and cost savings.

Heat treating is an essential process in the development of components for a wide range of industries.

Take a closer look at how the uniform rapid quenching of the new Quintus QIH 122 URQ Hot Isostatic Press strengthens the capabilities of Lake City Heat Treating.

Ceramic fiber-lined furnaces are general purpose box furnaces for batch heat treating in air atmosphere.

A TITAN H2 vacuum heat treating system with two-bar gas quenching from Ipsen satisfies the strict legal requirements of the medical industry.

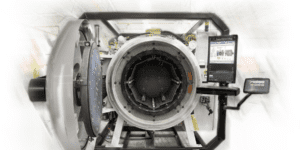

AMETEK Land has launched a retraction system for thermal imagers, safeguarding the instrument and preventing overheating or damage in the event of loss of power, purge flow loss or cooling.

AMETEK Land’s lightweight Portable Furnace Thermal Imaging System is ideal for performing regular inspections and surveys, leading to prolonged furnace lifespans, optimized burner efficiency, reduced energy consumption, and improved plant profitability.

L&L Special Furnace Co.’s XLE3436 box furnace will support the investment castings supplier’s tool and die production, along with tempering of finished castings.