Sawing Systems

To separate components into two or more pieces or to cut off an unwanted section of a part, a continuous cutting (band or rotary) or a reciprocating type saw cuts a narrow slit into the workpiece using a saw blade with narrowly spaced teeth. While each tooth takes a cut as the blade moves past the work, the number of teeth cutting at one time varies from two to ten or more depending on the thickness or diameter of the work. In most sawing operations, the work is held stationary and the saw blade is moved for cutting. Typical machines include band saws, circular saws, cold saws and abrasive cut-off machines, each designed for cutting effectiveness in specific applications.

Corporate Profile: Pat Mooney Saws

Celebrating 75 years in 2024!

Real time monitoring systems track the performance of band saws, correcting the process to minimize disruptions.

Discover what’s next for machine tools. It may be just the time to update your shop’s metal removal technologies and processes.

DoALL Sawing Products provides the industry’s most comprehensive inventory of metal-cutting products. With its long history of metal-cutting expertise, the company continues as a leader in band saw innovations.

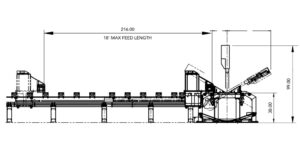

Fewer blade changes, one stop approaches, and automatic feeds and saws maximize productivity with little operator involvement.

Process Malfunction During Sawing: WIKUS Offers Digital Tool for Live Audiovisual Remote Service.

The cornerstone for Hunter Precision Tool is the sales, re-grinding and servicing of circular saw blades – a business division that continues to grow. At the core of this department is the VOLLMER CHD270 with an ND230 automation system. The company has recently invested in the VOLLMER VPulse 500 wire EDM machine.

Suhner USA, Inc.’s ROTOmax 2.2 offers applications in cutting machining, grinding, rust removal, brushing or polishing.